A manufacturing method for producing industrial pure titanium plate by adopting the second-fire process of medium and heavy plate rolling mill

A technology of industrial pure titanium and manufacturing method, applied in the direction of metal rolling, etc., can solve the problems of low investment and production cost, high production efficiency, surface quality, poor structure performance, etc., to improve surface quality, improve performance quality, and improve products performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

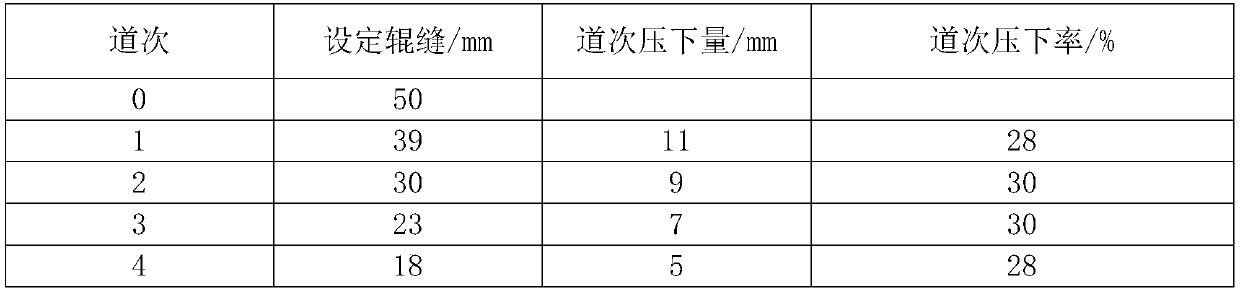

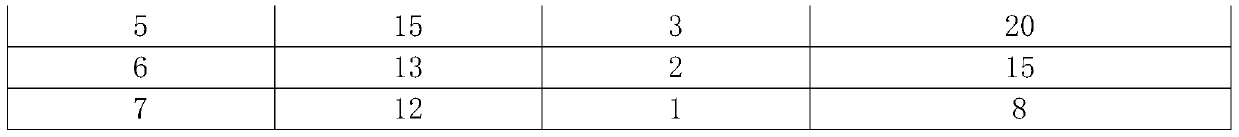

[0021] A manufacturing method for producing industrial pure titanium plates by adopting the second fire forming process of a medium and heavy plate rolling mill. The chemical composition and content of the forging blank are: Fe is 0.01wt%, C is 0.04wt%, N is 0.002wt%, H is 0.004wt%, O is 0.07wt%, P is 0.012wt%, S is 0.002wt% %, the rest is Ti and inevitable impurities. The hot rolling process is as follows: a forging blank with a thickness of 150mm and a width of 1200mm is placed in the preheating section of a heating furnace at 400°C, preheating for 60min, heating section 900°C, heating time 200min, soaking section temperature 920°C, soaking time 60min, In the soaking section, the lower surface temperature of the control blank is 10°C higher than the upper surface temperature, and the heating furnace discharge temperature is 910°C. After the heating furnace is discharged, high-pressure water dephosphorization is carried out, and the dephosphorization pressure is 12MPa. The re...

Embodiment 2

[0029] A manufacturing method for producing industrial pure titanium plates by adopting the second igneous material process of a medium and heavy plate rolling mill. The chemical composition and content of the forging blank are: Fe is 0.03wt%, C is 0.013wt%, N is 0.005wt%, H is 0.001wt%, O is 0.07wt%, P is 0.012wt%, S is 0.002wt% %, the rest is Ti and inevitable impurities. The hot rolling process is as follows: a forging blank with a thickness of 150mm and a width of 1200mm is placed in the preheating section of the heating furnace at 500°C, 40min in preheating, 950°C in the heating section, heating time 150min, soaking section temperature 940°C, soaking time 90min, The discharge temperature of the heating furnace is 935℃. In the soaking section, the lower surface temperature of the blank is controlled to be 10℃ higher than the upper surface temperature. After the heating furnace is discharged, high-pressure water dephosphorization is carried out, and the dephosphorization pre...

Embodiment 3

[0038] A manufacturing method for producing industrial pure titanium plates by adopting the second igneous material process of a medium and heavy plate rolling mill. The chemical composition and content of the forging blank are: Fe is 0.02wt%, C is 0.017wt%, N is 0.004wt%, H is 0.001wt%, O is 0.06wt%, P is 0.011wt%, and S is 0.003wt %, the rest is Ti and inevitable impurities. The hot rolling process is as follows: a forging blank with a thickness of 150mm and a width of 1200mm is placed in the preheating section of the heating furnace at 460°C, preheating for 50min, heating section 950°C, heating time 200min, soaking section temperature 930°C, soaking time 60min, The temperature of the heating furnace is 935℃. After exiting the heating furnace, high-pressure water dephosphorization is carried out, and the dephosphorization pressure is 12MPa. After dephosphorization, it enters the medium and heavy plate four-roll reversible rolling mill for 5 round-trip rolling, and the rolling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com