Baseplate of integral heat-preservation and energy-saving plate and preparation method thereof

An integrated board and substrate technology, applied in the field of building decoration materials, to save construction time and labor costs, and achieve the effect of excellent performance and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

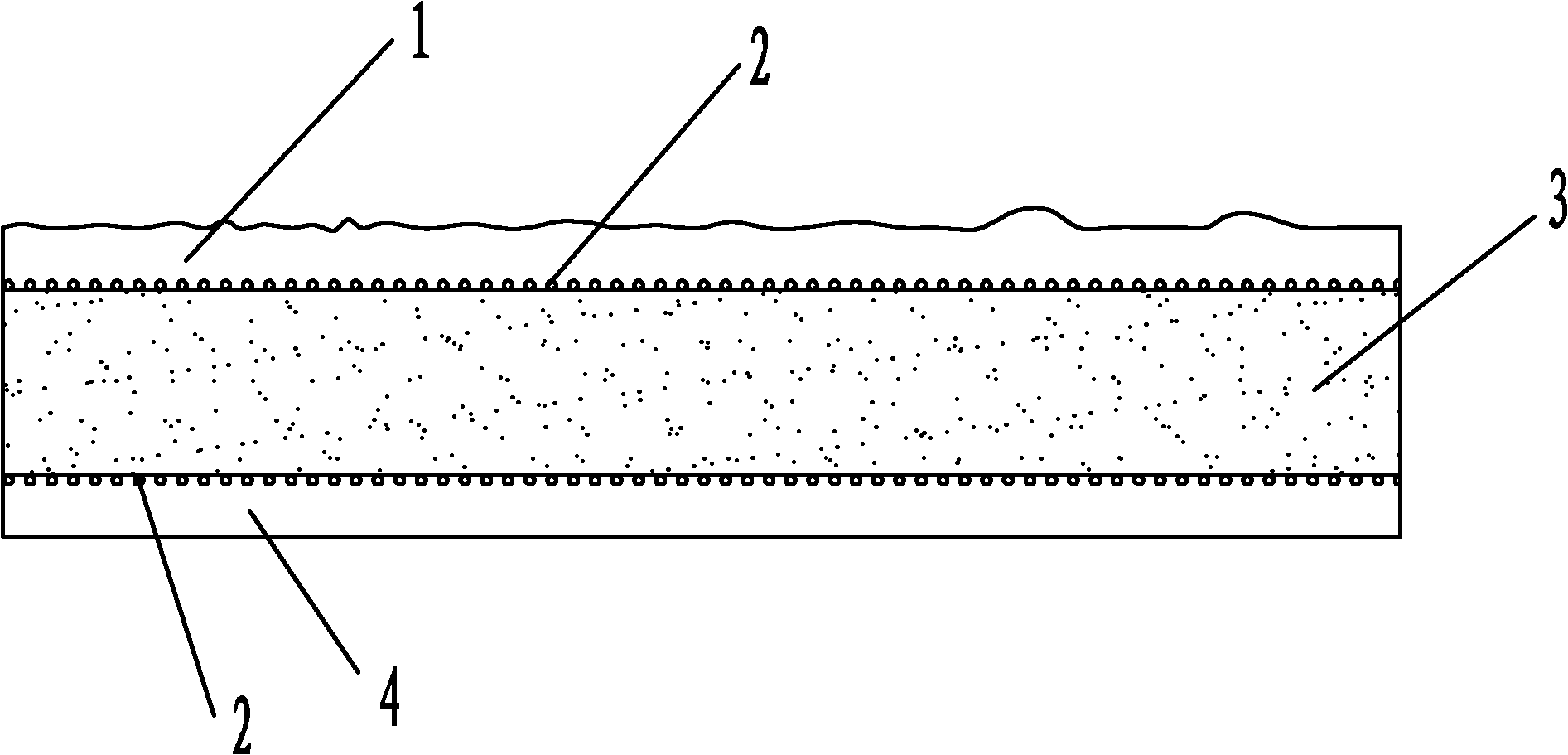

[0028] A thermal insulation and energy-saving integrated board substrate, which is characterized in that it is mainly composed of a surface layer 1, a structurally reinforced fiber mesh 2, an intermediate layer 3, a structurally reinforced fiber mesh 2, and a bottom layer 4 connected in sequence, wherein:

[0029] The surface layer is mainly composed of the following materials in parts by weight of 10g each,

[0030] 10g of aluminum magnesium silicate powder, 10g of lightly burned magnesium powder, 10g of magnesium gelling material regulator,

[0031] Silica fume powder 10g, phosphoric acid or sulfate powder 10g, ore tailing powder 10g,

[0032] 10g of mineral sand or colored quartz sand, 10g of iron oxide ore powder; 10g of mineral wool fiber;

[0033] Reinforced glass fiber 10g, polypropylene fiber 10g;

[0034] The middle layer and the bottom layer are mainly composed of the following parts by weight of each 10g material,

[0035] 10g of aluminum magnesium silicate powde...

Embodiment 2

[0048] A thermal insulation and energy-saving integrated board substrate, the surface layer is mainly composed of the following materials in parts by weight of 10g each,

[0049] 500g of aluminum magnesium silicate powder, 500g of lightly burned magnesium powder, 500g of magnesium gelling material regulator,

[0050] Silica fume powder 200g, phosphoric acid or sulfate powder 100g, ore tailing powder 700g,

[0051] 700g of mineral sand or colored quartz sand, 200g of iron oxide ore powder; 300g of mineral wool fiber;

[0052] Reinforced glass fiber 300g, polypropylene fiber 300g;

[0053] The middle layer and the bottom layer are mainly composed of the following parts by weight of each 10g material,

[0054] 500g of aluminum magnesium silicate powder, 500g of lightly burned magnesium powder, 500g of puffed granules for plastic industry; 300g of magnesium cementitious material regulator, 200g of blast furnace slag powder, 300g of fly ash, 100g of phosphoric acid or sulfate pow...

Embodiment 3

[0067] A thermal insulation and energy-saving integrated board substrate, the surface layer is mainly composed of the following materials in parts by weight, each part is 10g,

[0068] 200g of aluminum magnesium silicate powder, 50g of lightly burned magnesium powder, 50g of magnesium gelling material regulator,

[0069] Silica fume powder 20g, phosphoric acid or sulfate powder 10g, ore tailing powder 70g,

[0070] 100g of mineral sand or colored quartz sand, 20g of iron oxide ore powder; 30g of mineral wool fiber;

[0071] Reinforced glass fiber 30g, polypropylene fiber 30g;

[0072] The middle layer and the bottom layer are mainly composed of the following parts by weight of each 10g material,

[0073] 200g of aluminum magnesium silicate powder, 150g of lightly burned magnesium powder, 50g of puffed granules for plastic industry; 30g of magnesium cementitious material regulator, 20g of blast furnace slag powder, 30g of fly ash, 80g of phosphoric acid or sulfate powder, qua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com