Bionic bone repair material having good machinery performance and biological activity and preparation method thereof

A technology of bioactivity and mechanical properties, applied in medical science, prosthesis, coating, etc., can solve the problems of limited bioactivity improvement of PCL stents, uneven distribution of β-TCP, complex mixing process, etc., to improve biological Effects of activity, complete void connectivity, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment provides a method for preparing a bionic bone repair material with good mechanical properties and biological activity, including the following specific steps:

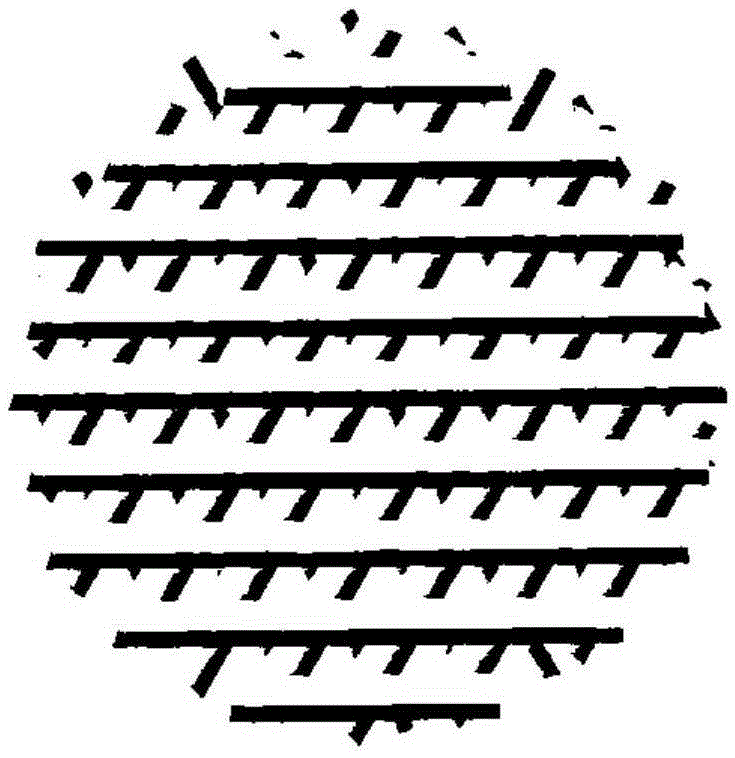

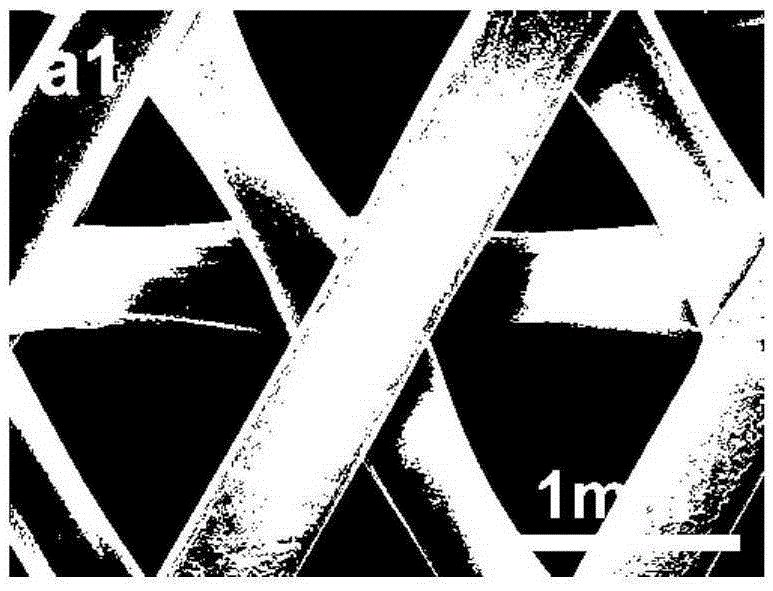

[0050] Step (1): Use rapid prototyping technology to 3D print large-aperture PCL scaffolds to obtain a primary structure, such as figure 1 ,

[0051] Establish a CAD model of a three-dimensional PCL bracket with a pore size of 100 μm through computer-aided design software, convert the CAD model into an STL. Printing, when the three-dimensional stent is printed, the direction of the nozzle shape is stacked layer by layer according to (0°, 60°, 120°);

[0052] The specific steps of 3D scaffold printing include:

[0053] A. Put the PCL granule raw material into the melter of the rapid prototyping machine and heat it to 50°C to make the PCL material flow;

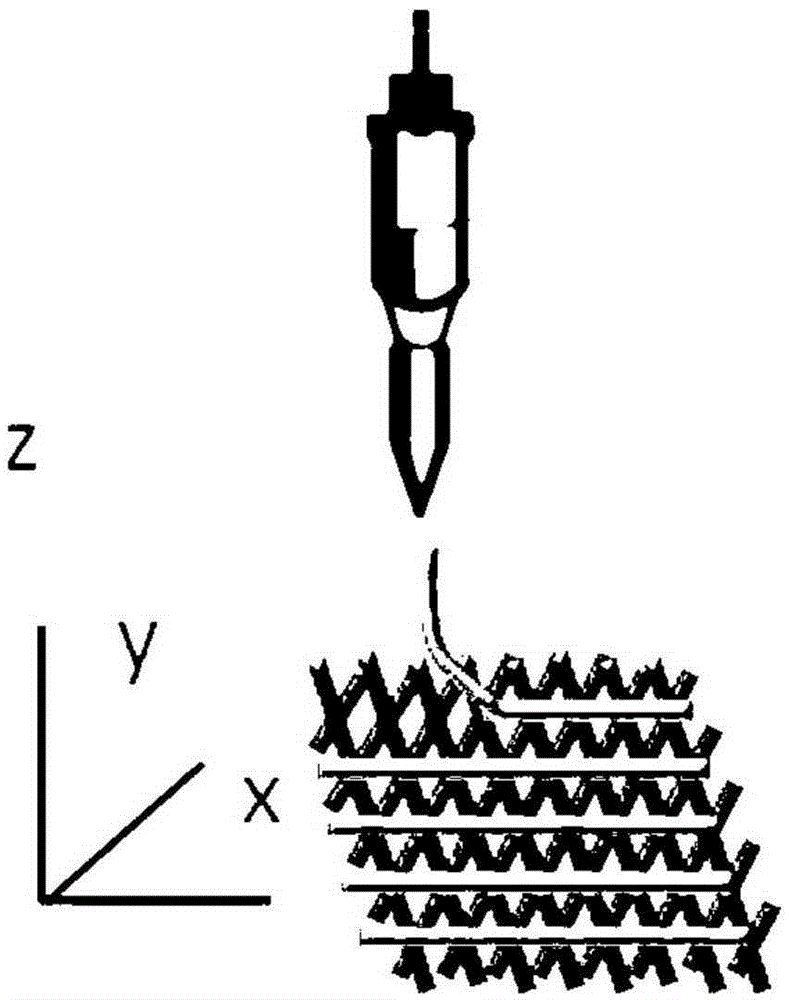

[0054] B. If figure 2 As shown, according to the CAD graphics in STL. format, under the control of the calculation, the flowing PCL material...

Embodiment 2

[0073] This embodiment provides a method for preparing a bionic bone repair material with good mechanical properties and biological activity, including the following specific steps:

[0074] Step (1): Use rapid prototyping technology to 3D print large-aperture PCL scaffolds to obtain a primary structure, such as figure 1 ,

[0075] The CAD model of the three-dimensional PCL bracket with a pore size of 1500 μm is established by computer-aided design software, and the CAD model is converted into an STL. format file, which is then input into the data processing software of the fusion molding machine after layering processing, and the three-dimensional bracket is made by using the 3DP molding system Printing, when the three-dimensional stent is printed, the direction of the nozzle shape is stacked layer by layer according to (0°, 90°);

[0076] The specific steps of 3D scaffold printing include:

[0077] A. Put the PCL granule raw material into the melter of the rapid prototypin...

Embodiment 3

[0097] This embodiment provides a method for preparing a bionic bone repair material with good mechanical properties and biological activity, including the following specific steps:

[0098] Step (1): Use rapid prototyping technology to 3D print large-aperture PCL scaffolds to obtain a primary structure, such as figure 1 ,

[0099] Establish a CAD model of a three-dimensional PCL bracket with a pore size of 1000 μm through computer-aided design software, convert the CAD model into an STL. Printing, when the three-dimensional stent is printed, the direction of the nozzle shape is stacked layer by layer according to (0°, 60°, 120°);

[0100] The specific steps of 3D scaffold printing include:

[0101] A. Put the PCL particle raw material into the melter of the rapid prototyping machine and heat it to 120°C to make the PCL material flow;

[0102] B. If figure 2 As shown, according to the CAD graphics in STL. format, under the control of the calculation, the flowing PCL mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com