A kind of inorganic-inorganic nano-hybrid material with double mesoporous core-shell structure and its preparation method and application

A core-shell structure and hybrid material technology, applied in the field of nano-hybrid materials and their preparation, can solve the problems of component stability, insufficient consistency, cumbersome preparation methods, and difficult industrialization, and achieve biomedical application prospects. The effect of broad, few process steps and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

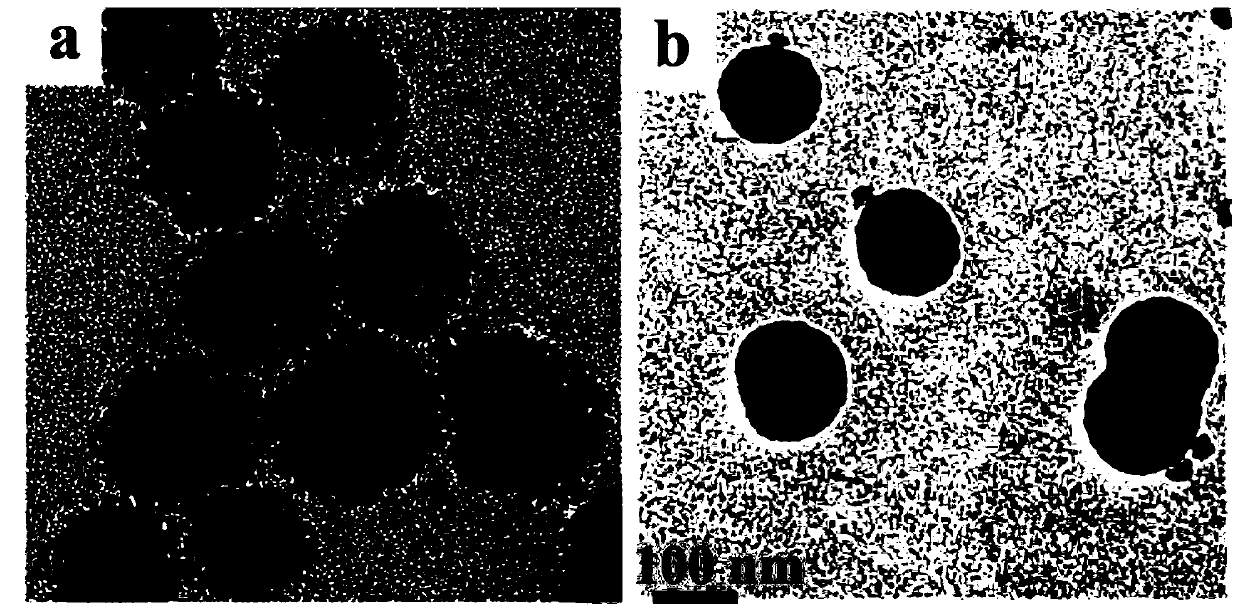

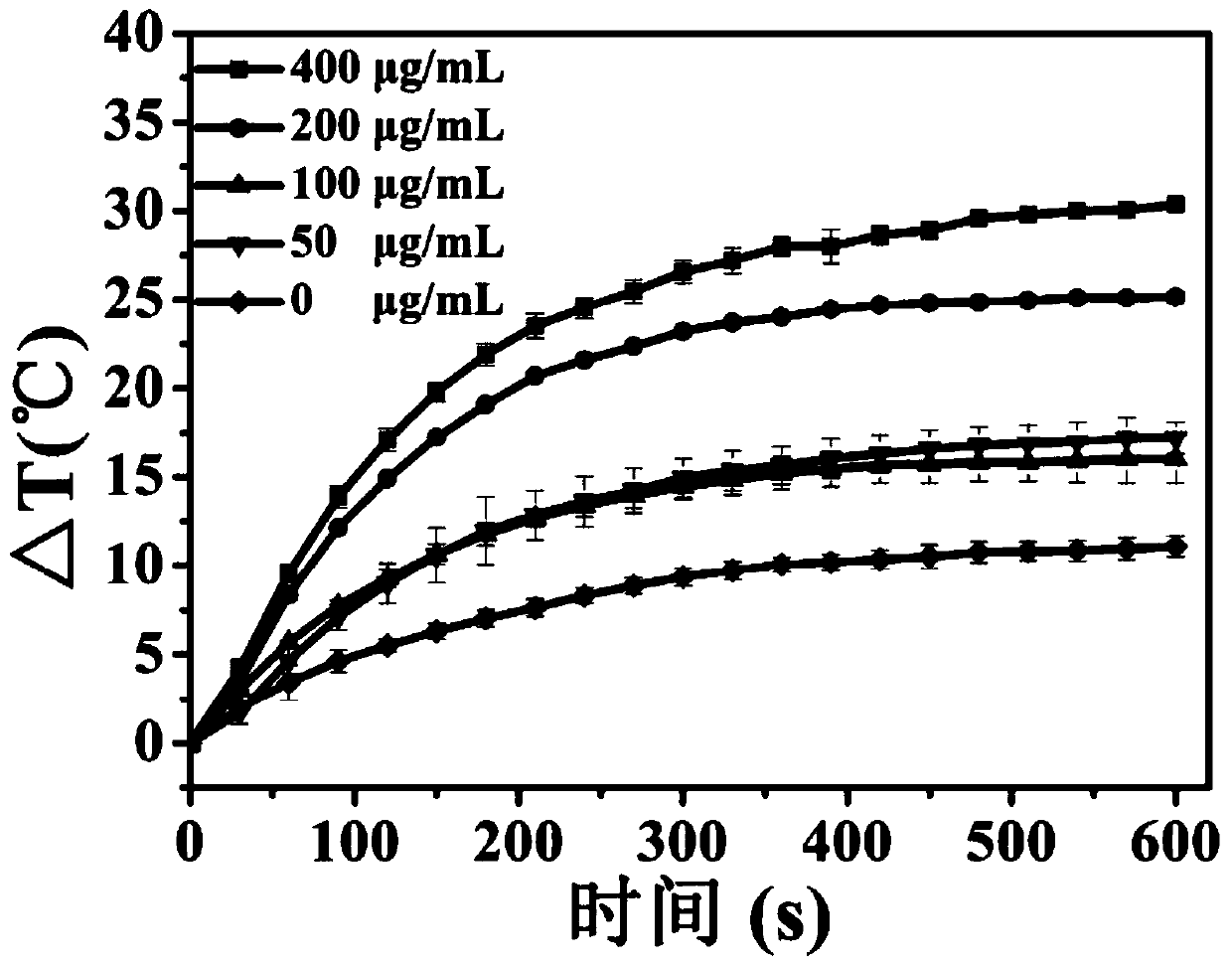

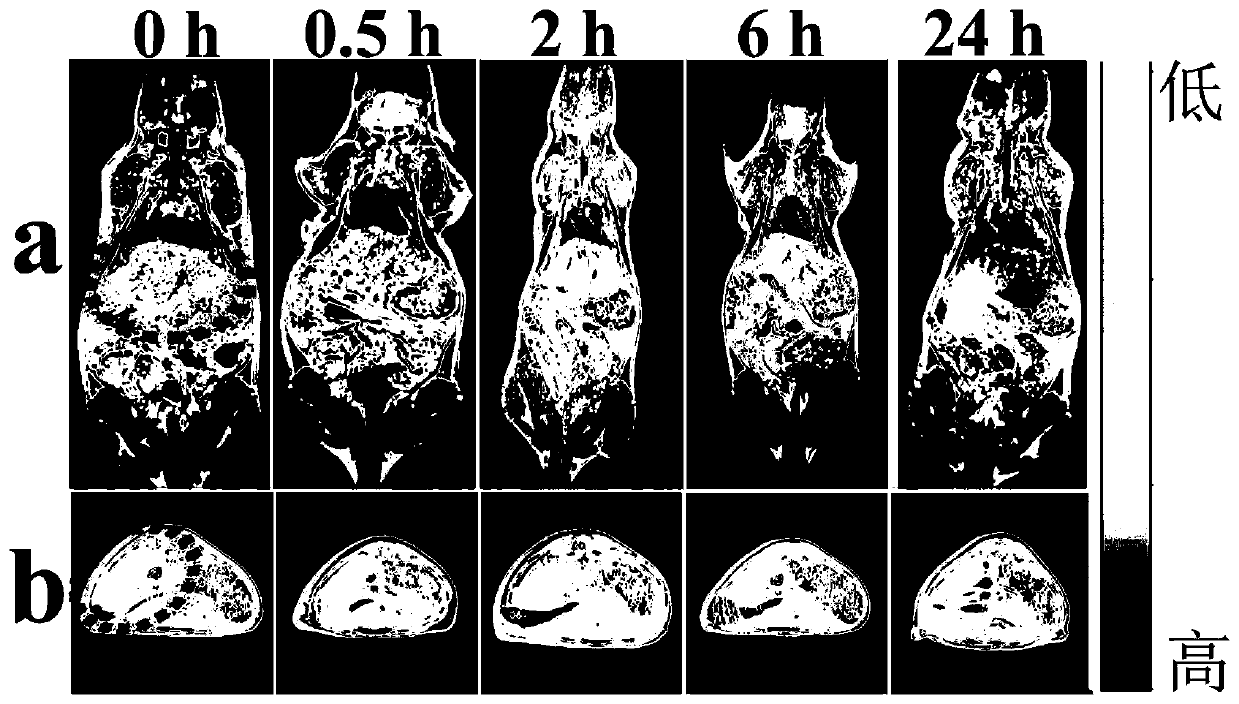

[0030] The platinum-gadolinium nano-hybrid material with dual mesoporous core-shell structure and its preparation method provided in this embodiment comprise the following steps:

[0031] (1) Using N, N-dimethylhexadecyl ammonium bromide sodium acetate (OTAB-Na) as a surfactant, using ascorbic acid to reduce chloroplatinic acid to synthesize mesoporous inorganic platinum nanoparticles: 80 mg surface Active agent N,N-dimethylhexadecyl ammonium bromide sodium acetate (OTAB-Na) was added to 10mL deionized water, heated to 70°C to dissolve, then added 2mL0.01mol / L chloroplatinic acid aqueous solution and 2mL0. 2 mol / L fresh ascorbic acid aqueous solution, stirred for 3 hours, centrifuged, washed, and the product was dissolved in deionized water to form a dispersion of mesoporous platinum nanoparticles.

[0032] (2) Using cetyltrimethylammonium bromide (CATB) as a surfactant, wrap mesoporous silica shell on the surface of mesoporous inorganic nanoparticles, and then remove CTAB to ...

Embodiment 2

[0040] The palladium-gadolinium nano-hybrid material with dual mesoporous core-shell structure and its preparation method, material and application provided in this example are basically the same as those in Example 1, except that it includes the following steps:

[0041] (1) Using N,N-dimethylhexadecyl ammonium bromide sodium acetate (OTAB-Na) as a surfactant, using ascorbic acid to reduce palladium chloride to synthesize mesoporous inorganic palladium particles: 100mg surface active The solution (OTAB-Na) was added to 10 mL of deionized water, heated to 50°C to dissolve, then 1 mL of 0.01 mol / L palladium chloride aqueous solution and 1 mL of 0.2 mol / L fresh ascorbic acid aqueous solution were added, stirred for 1 h, centrifuged, washed, and the product was dissolved. In deionized water, a dispersion of mesoporous palladium nanoparticles was formed.

[0042] (2) Using cetyltrimethylammonium bromide (CATB) as a surfactant, wrap mesoporous silica shell on the surface of mesopor...

Embodiment 3

[0046] The gold-gadolinium nano-hybrid material with dual mesoporous core-shell structure and its preparation method, material and application provided in this example are basically the same as those in Example 1 or 2, except that it includes the following steps:

[0047] (1) Using N,N-dimethylhexadecyl ammonium bromide sodium acetate (OTAB-Na) as a surfactant, using ascorbic acid to reduce chloroauric acid to synthesize mesoporous inorganic gold particles: 90mg surface active Add the agent (OTAB-Na) into 10mL deionized water, heat up to 100°C to dissolve, then add 1.5mL 0.01mol / L chloroauric acid aqueous solution and 1.5mL 0.2mol / L fresh ascorbic acid aqueous solution, stir for 2h, centrifuge, wash, The product is dissolved in deionized water to form a dispersion of mesoporous gold nanoparticles.

[0048] (2) Using cetyltrimethylammonium bromide (CATB) as a surfactant, wrap mesoporous silica shell on the surface of mesoporous inorganic nanoparticles, and then remove CTAB to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com