Steam box and microwave oven integrated machine

A technology of microwave ovens and all-in-one machines, which is applied in microwave heating, household stoves/stoves, steam cooking utensils, etc., and can solve problems such as the impact of heater life, dry heating of heaters, and abnormal heat transfer of heaters, so as to increase safety and reliability, reducing depth space, and improving cooking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

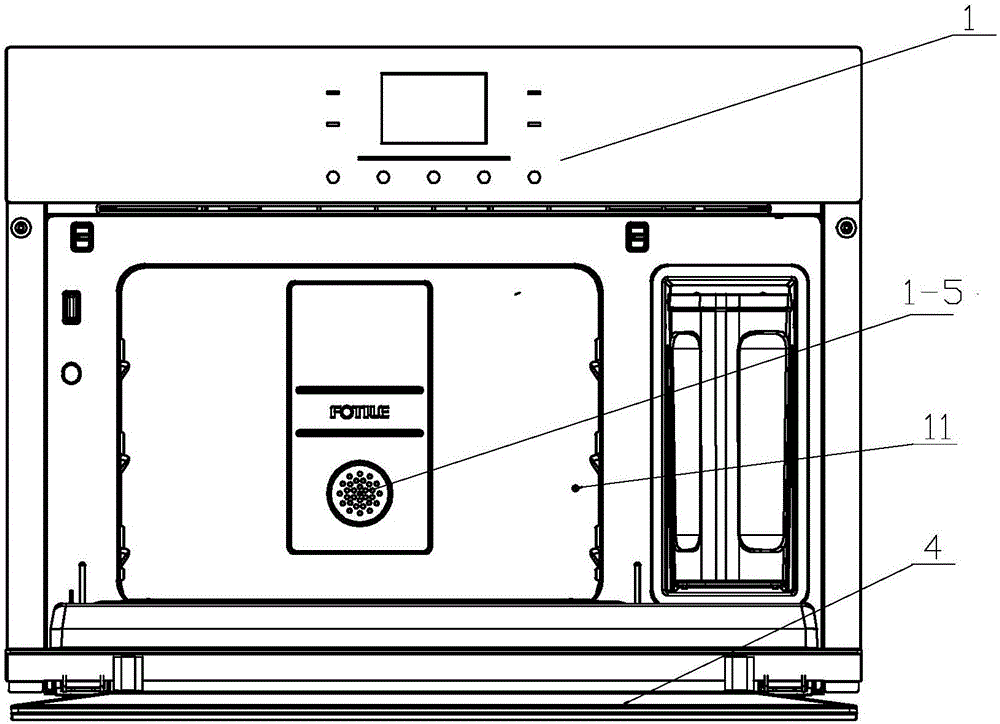

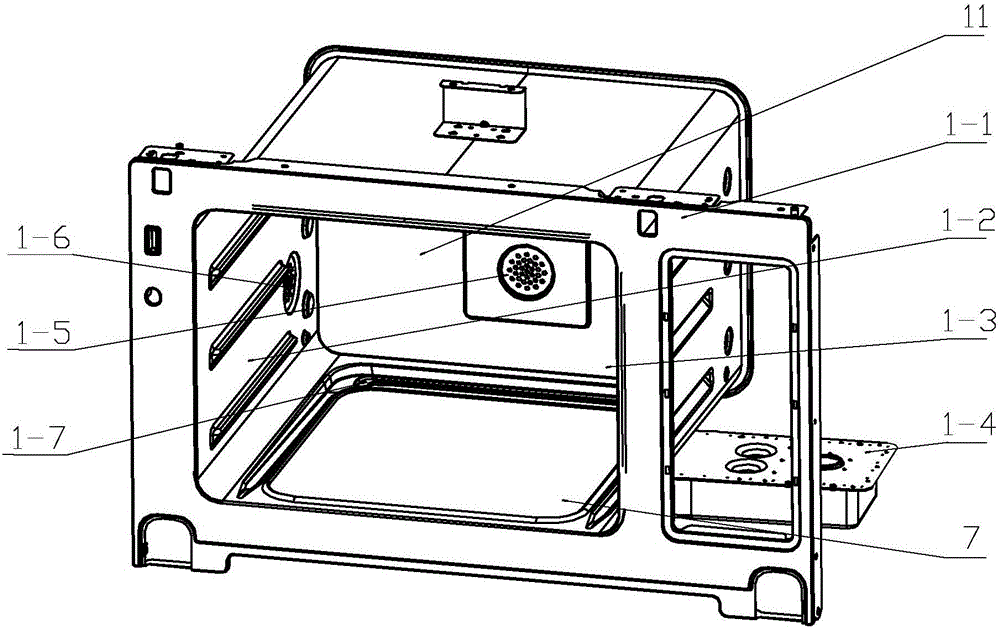

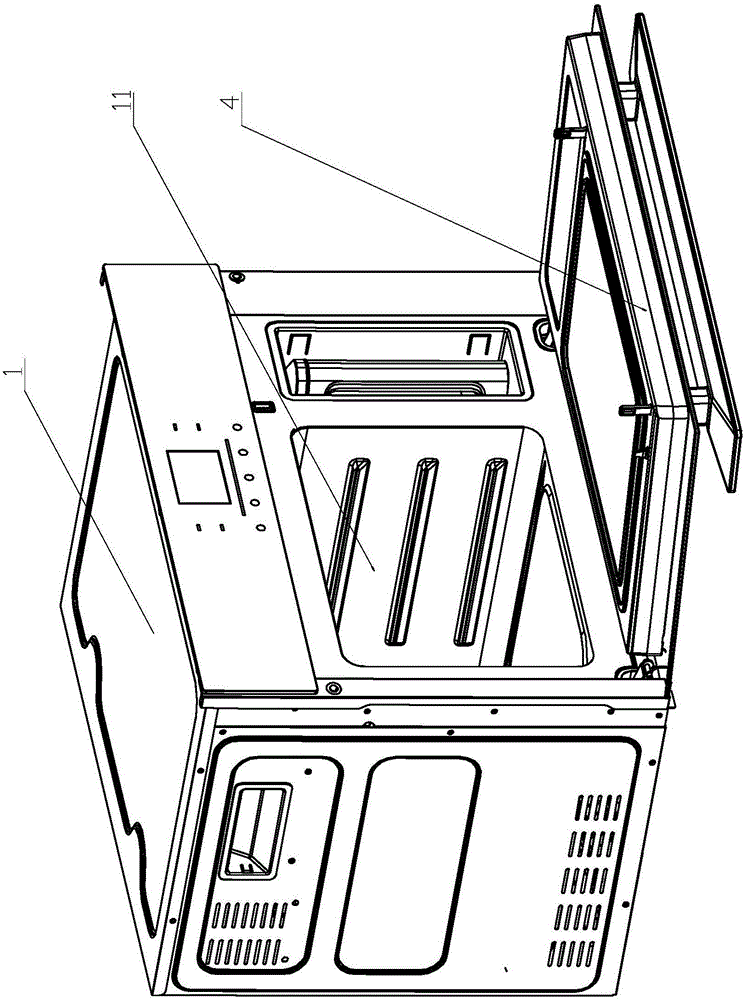

[0034] Such as figure 1The shown steam box and microwave oven integrated machine includes a box body 1, a cooking chamber cavity 11 arranged in the box body 1, and a steam generating system arranged in the box body 1 for providing steam to the cooking chamber cavity 11, which is arranged in The microwave generating system used in the cooking chamber cavity 11 to provide microwaves in the cabinet 1 is arranged on the front side of the cabinet 1 for sealing the oven door assembly 4 of the cooking chamber cavity 11, and is arranged in the cabinet 1 together with the steam generating system A control system connected with the microwave generating system.

[0035] Wherein said steam generating system comprises a steam generator 2 for generating steam, a water tank 2-1, a solenoid valve 2-3, connecting pipelines and a two-way water pump 2-4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com