Nano treatment liquid for increasing yield and injection of oil-water wells

A technology for oil-water wells and treatment fluids, applied in the field of nano-treatment fluids, which can solve problems such as low success rate of measures, small acid penetration distance, and decline in oil well production, so as to improve oil recovery, improve seepage environment, and improve water flooding. Effect of Sweep Coefficient and Displacement Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

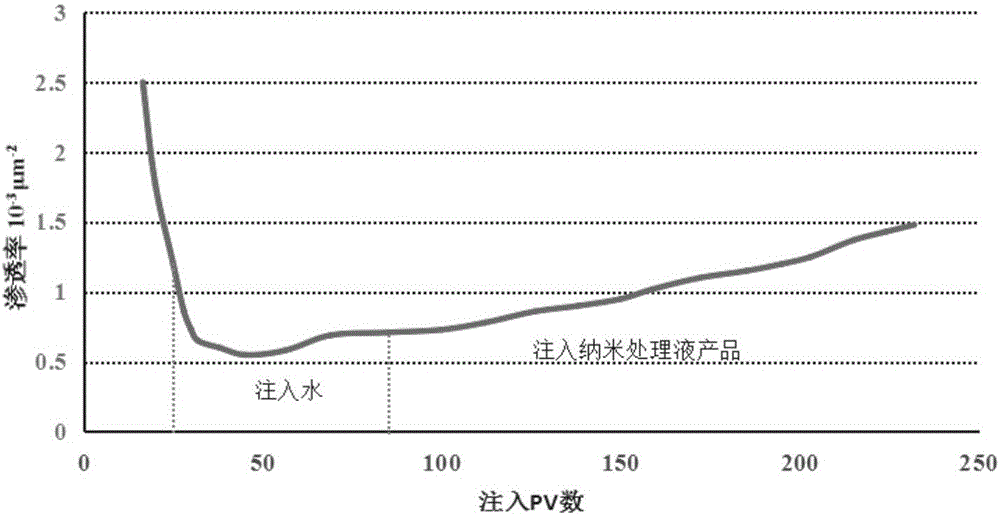

Image

Examples

Embodiment 1

[0021] A nano-treatment liquid for increasing production and injection of oil and water wells. The raw materials in parts by weight include: 3 parts of ammonium chloride, 10 parts of water-soluble demulsifier, 5 parts of methanol, 5 parts of sodium hexametaphosphate, 20 parts of hydrochloric acid, 20 parts of maleic acid, 10 parts of ethylenediamine tetramethylene phosphate, 2 parts of hydrofluoric acid, 1.5 parts of corrosion inhibitor soil acid, 0.5 parts of drainage aid, 30 parts of fatty alcohol, sodium dodecylbenzenesulfonate 3 parts, 3 parts of chelating agents, 2 parts of sodium diethylenetriaminepentaacetate, 2 parts of methanesulfonic acid, 12.5 parts of surfactants; the raw materials of described surfactants according to parts by weight include: 0.5 parts of nano silicon dioxide, 2 parts of zeolite, 3 parts of sodium carbonate, 2 parts of anionic surfactant, 5 parts of sodium silicate.

Embodiment 2

[0023] A nano-treatment fluid for increasing production and injection of oil and water wells. The raw materials in parts by weight include: 3.5 parts of ammonium chloride, 11 parts of water-soluble demulsifier, 6 parts of methanol, 6 parts of sodium hexametaphosphate, 22 parts of hydrochloric acid, poly 22 parts of maleic acid, 11 parts of ethylenediamine tetramethylene phosphate, 3 parts of hydrofluoric acid, 1.6 parts of corrosion inhibitor clay acid, 0.6 parts of drainage aid, 32 parts of fatty amine, sodium dodecylbenzenesulfonate 3.5 parts, 3.5 parts of chelating agents, 2.5 parts of sodium diethylenetriaminepentaacetate, 2.5 parts of methanesulfonic acid, 14.3 parts of surfactants; the raw materials of said surfactants in parts by weight include: 0.6 parts of nano silicon dioxide, 2.2 parts of zeolite, 3.5 parts of sodium carbonate, 2.5 parts of anionic surfactant, and 5.5 parts of sodium silicate.

Embodiment 3

[0025] A nano-treatment liquid for increasing production and injection of oil and water wells. The raw materials in parts by weight include: 4 parts of ammonium chloride, 12 parts of water-soluble demulsifier, 8 parts of methanol, 8 parts of sodium hexametaphosphate, 25 parts of hydrochloric acid, poly 258 parts of maleic acid, 12 parts of ethylenediamine tetramethylene phosphate, 4 parts of hydrofluoric acid, 1.8 parts of corrosion inhibitor clay acid, 0.8 parts of drainage aid, 35 parts of triethanolamine, sodium dodecylbenzenesulfonate 4 parts, 4 parts of chelating agents, 3 parts of sodium diethylenetriaminepentaacetate, 3 parts of methanesulfonic acid, 16.3 parts of surfactants; the raw materials of described surfactants according to parts by weight include: 0.8 parts of nano silicon dioxide, 2.5 parts of zeolite, 4 parts of sodium carbonate, 3 parts of anionic surfactant, 6 parts of sodium silicate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com