Machining device for precise automobile tail gas exhaust pipe

A technology of automobile exhaust and processing equipment, which is applied in the direction of metal processing equipment, push-out equipment, perforation tools, etc., can solve the problem of inability to meet the environmental protection emission requirements of automobile exhaust, the inability to meet the environmental protection emission standards of automobile exhaust, and the unstable formation of the discharge hole of the exhaust pipe and other problems, to achieve the effect of good braking performance and balance effect, enough roundness of the hole, and no deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended purpose, the specific implementation modes of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

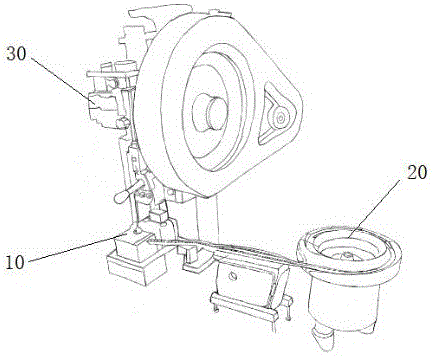

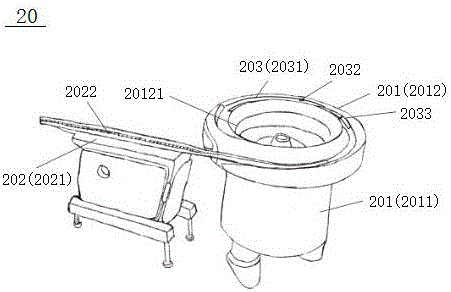

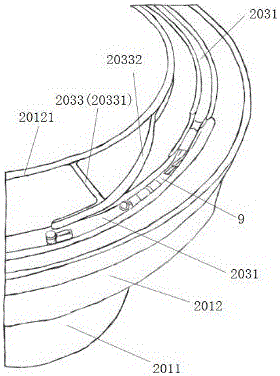

[0033] Please refer to figure 1 , the embodiment of the present invention provides a precision automobile exhaust pipe processing equipment, which is characterized in that it includes a feeding device 20, a stamping die 10, an automatic stamping transmission device 30 and a counting control device, wherein the feeding device 20 is connected to the stamping die The feeding port of 10 continuously conveys materials for the stamping die 10; the automatic stamping transmission device 30 is located above the stamping die 10 to provide power for the stamping die 10; the counting control device is electrically connected with the automatic stamping transmission device 30 for automatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com