Method for machining raw materials

A processing method and technology of raw materials, applied in the direction of electrical program control, digital control, etc., to achieve the effect of improving production and high material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

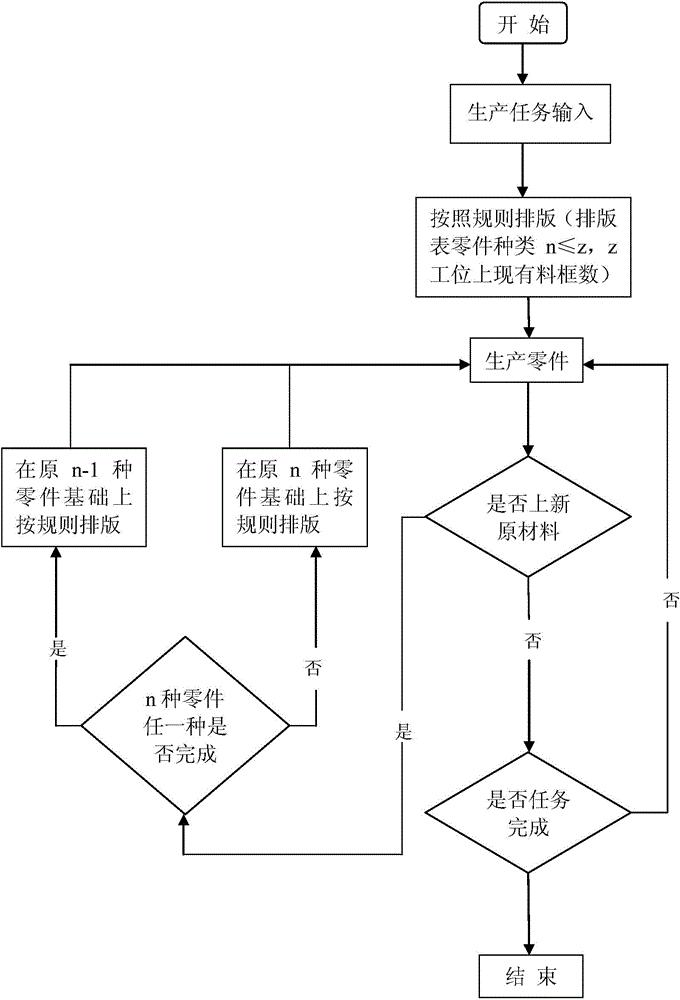

[0012] In order to overcome the contradiction between automatic sorting requiring fewer types of parts and the reasonable combination of different types of parts to improve the utilization rate of materials, and to solve the problem of requiring more material boxes due to the large number of parts, this raw material processing method adopts the automatic typesetting logic of the blanking equipment , not only improves the utilization rate of materials, realizes efficient automatic sorting function, but also achieves the function of automatic sorting of infinite kinds of materials through the recycling of limited material boxes. This raw material processing method is suitable for related blanking work such as plates and profiles. For plates, according to the needs of subsequent processes, the parts formed by blanking can be rectangles, parallelograms, trapezoids, irregular polygons, circles, etc. ; For profiles, the parts formed by blanking are mainly reflected in the difference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com