Method for reducing the polysilicon surface roughness

A surface roughness and polysilicon technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of large leakage current of TFT, high surface roughness of polysilicon film, easy formation of parasitic capacitance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

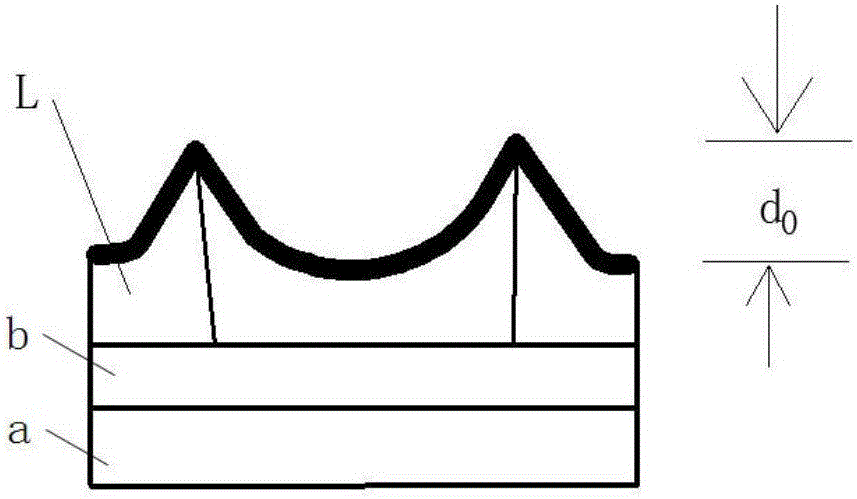

[0057] The method for reducing the surface roughness of polysilicon in this embodiment comprises the following steps:

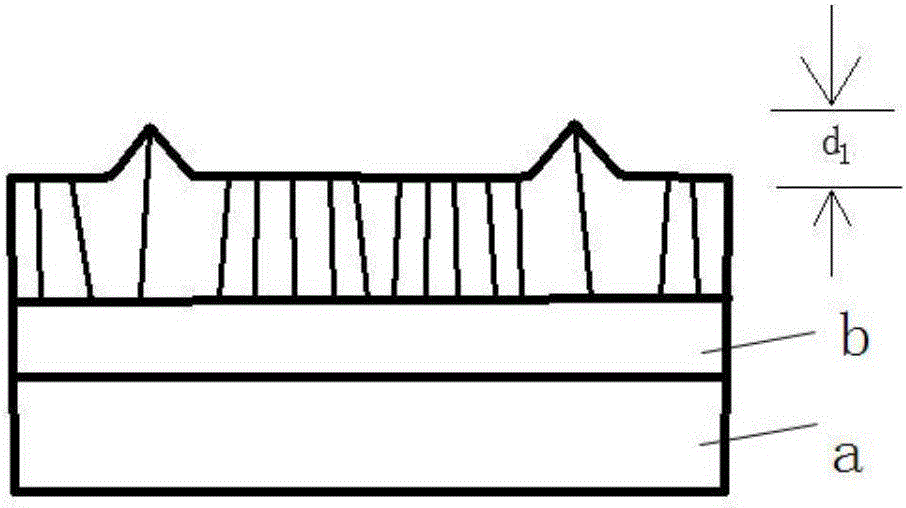

[0058] 1. Use O with a concentration of 5mg / L 3 Water contacts the surface of the polysilicon layer for oxidation treatment for 15 seconds, thereby forming a surface oxide layer;

[0059] 2. Contacting the surface oxide layer formed on the surface of the polysilicon layer with an HF solution with a concentration of 1 wt% for 40 seconds to obtain an oxidized and etched polysilicon layer;

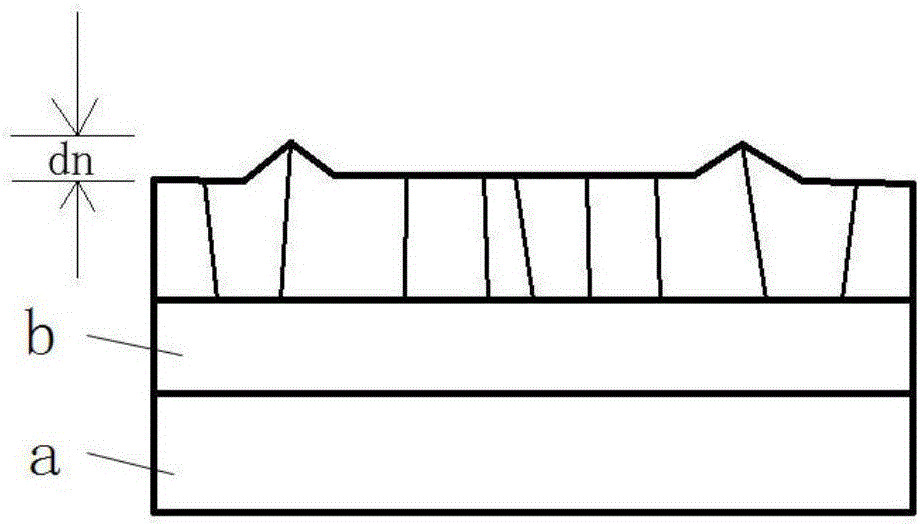

[0060] 3. Repeat the oxidation treatment of step 1 and the etching treatment of step 2 three times in sequence, thereby reducing the surface roughness of the polysilicon.

[0061] This embodiment controls O 3 The concentration of water is low, so that the thickness of the oxide layer on the surface after each oxidation treatment is also thinner. Subsequently, the polysilicon with the oxide layer on the surface is etched with a HF solution with a lower concentration. Due to...

Embodiment 2

[0064] The method for reducing the surface roughness of polysilicon in this embodiment is realized in the following steps:

[0065] 1. The buffer layer and the amorphous silicon layer are sequentially deposited on the glass substrate by PECVD method;

[0066] 2. Heat the amorphous silicon layer described in step 1 at 500° C. for 1.5 hours, and then carry out an excimer laser annealing treatment to the amorphous silicon layer to form a polysilicon layer;

[0067] 3. Use O with a concentration of 10mg / L 3 Water is contacted with the surface of the polysilicon layer formed in step 2 for oxidation treatment for 15 seconds, thereby forming a surface oxide layer;

[0068]4. Contact the surface oxide layer formed on the surface of the polysilicon layer with a concentration of 2wt% HF solution for etching for 50 seconds to obtain a polysilicon layer that has been oxidized and etched;

[0069] Fifth, repeating the oxidation treatment of step three and the etching treatment process of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com