Measuring system for particle moving trajectory of spray drier based on image method

A technology of spray dryer and running track, which is applied in the field of physical measurement, can solve the problems of sticking to the wall of the drying tower and the material cannot contact the air, etc., and achieve the effect of high degree of automation and accurate track measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

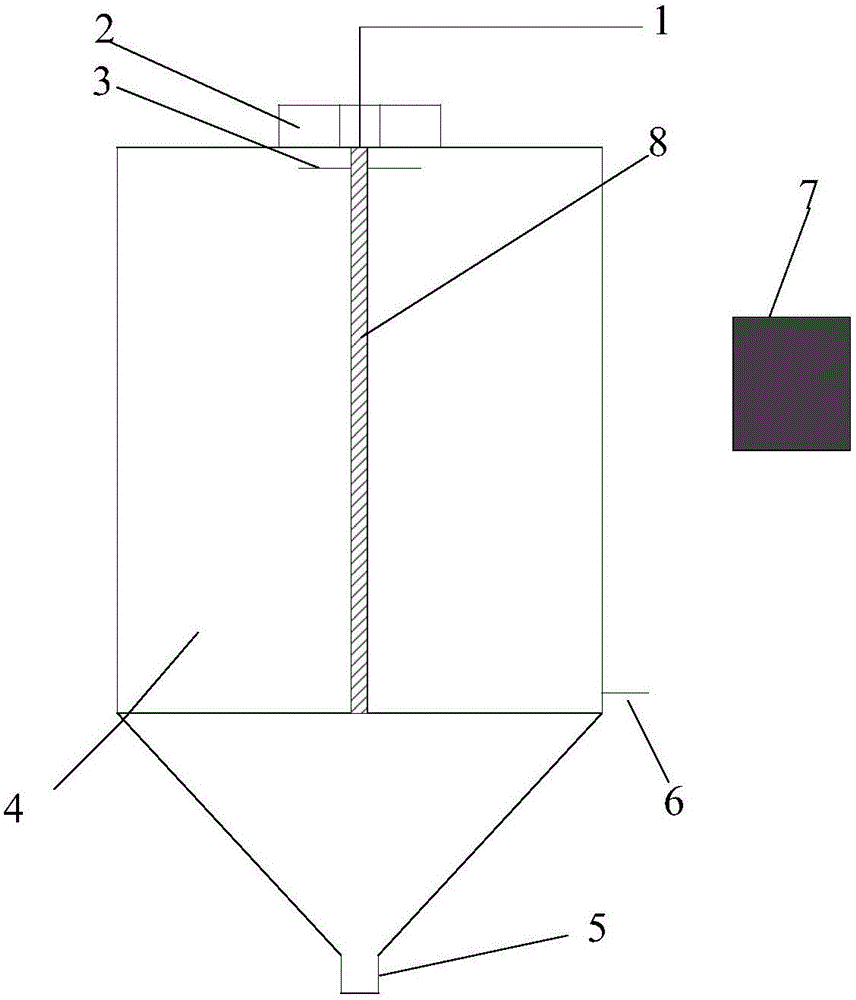

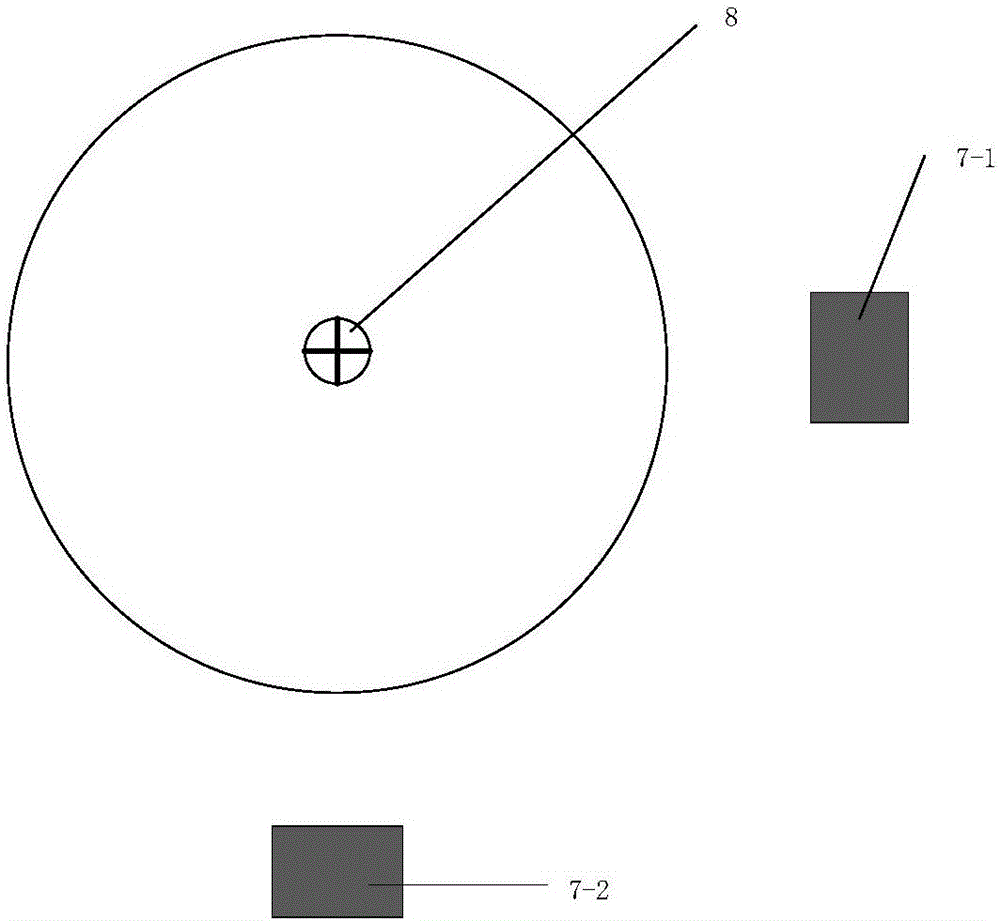

[0015] Such as figure 1 As shown, the spray dryer particle running trajectory measurement system based on the image method of the present invention includes a laser light source device 8, a CCD camera 7, an aluminum powder colloid and a spray drying device, and the spray drying device includes a volute hot air distributor 2, a fog Carburetor 3, raw material liquid inlet 1, drying chamber 4, heating medium circulation outlet 6 and material outlet 5.

[0016] Specifically, the drying chamber 4 is a closed chamber, the upper part is a cylinder, and the bottom is a cone, and a support device is provided at the boundary for installing the laser light source device 8, and the laser light source device 8 is located at the center of the cylinder b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com