Plate heat exchanger-capacitor evaporator and method for cryogenic decomposition of air

A plate heat exchanger, heat exchanger technology, applied in heat exchange equipment, heat exchanger shell, indirect heat exchanger, etc., can solve the problem of reducing heat exchange area, and achieve improved heat exchange efficiency and good heat exchange efficiency. , the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

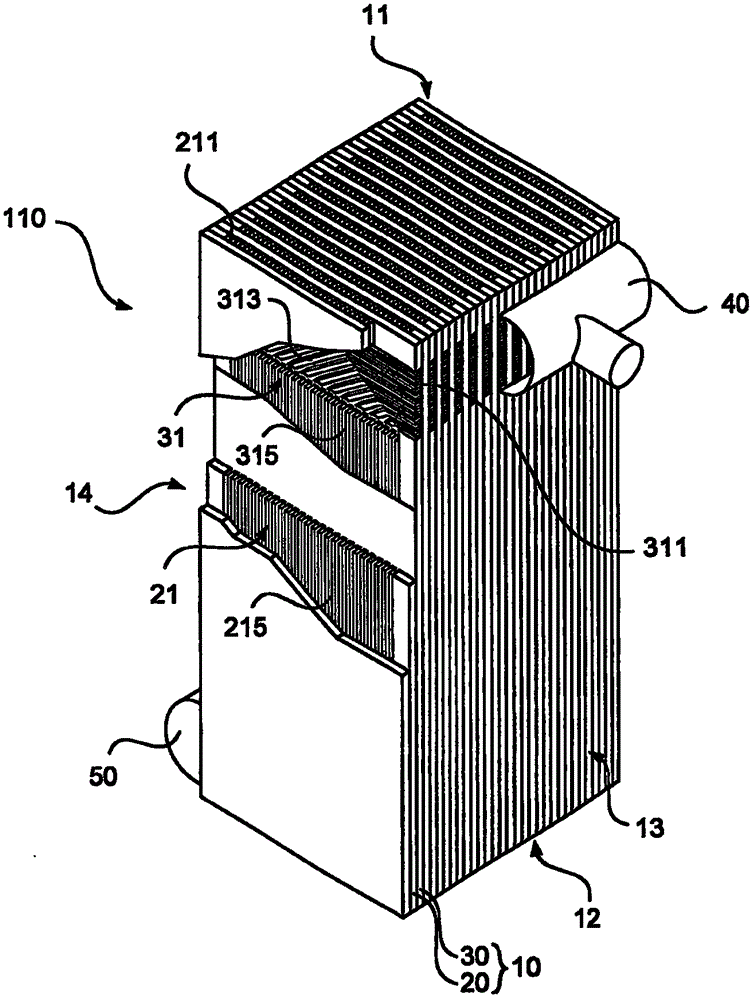

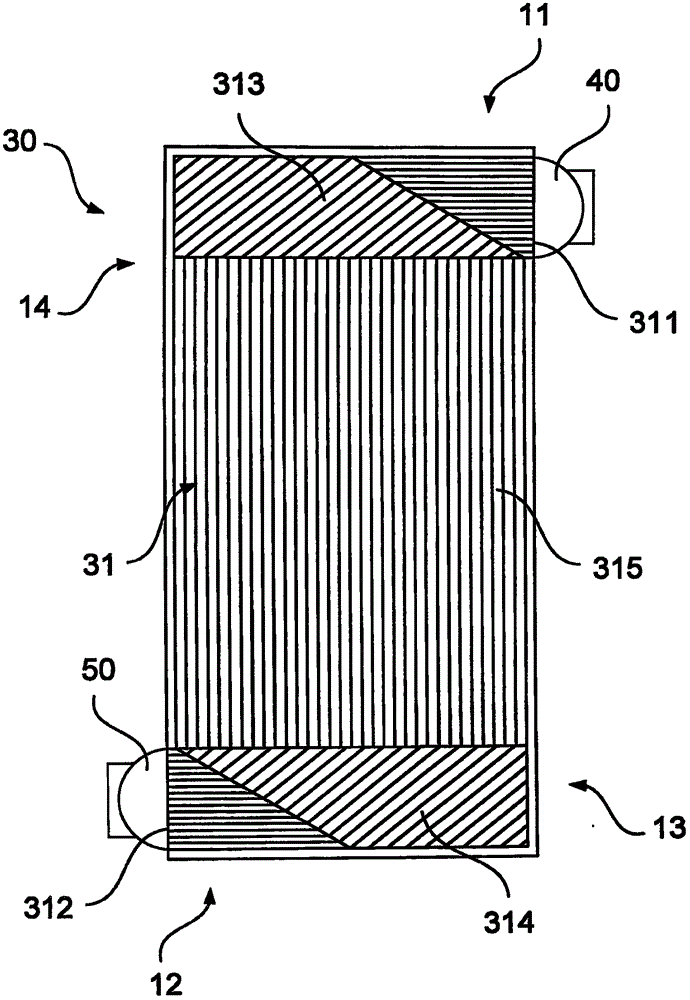

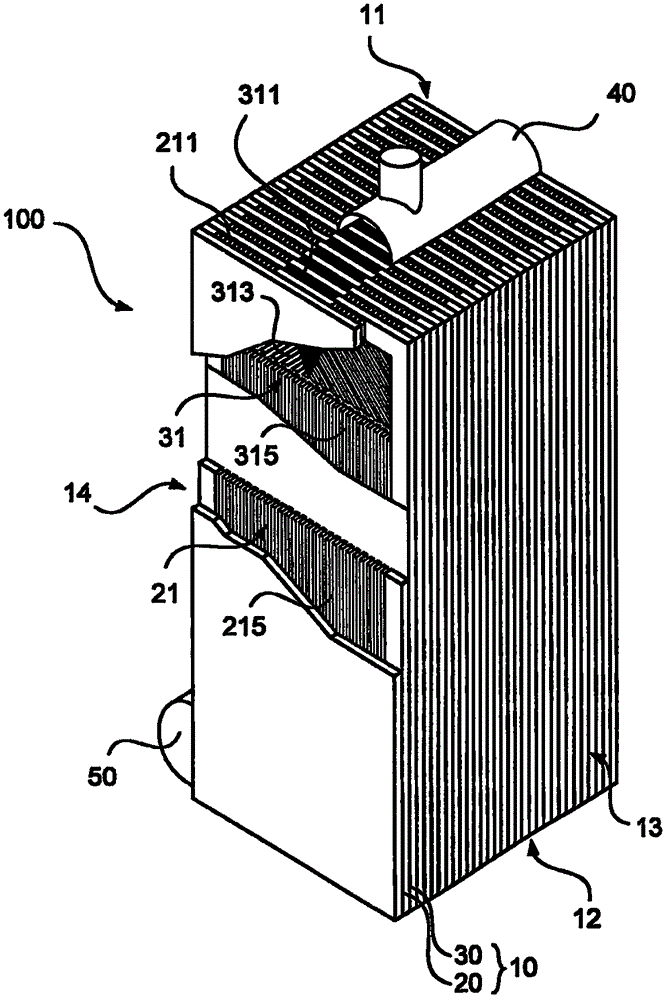

[0047] figure 1 A plate heat exchanger-condenser evaporator not according to the invention is shown schematically and partially opened. figure 1 The plate heat exchanger-condenser evaporator is indicated by 110 as a whole.

[0048] The heat exchanger block 10 of the plate heat exchanger-condenser evaporator is formed by an alternating arrangement of heat exchanger plates 20 and 30, wherein the heat exchanger plate 20 is hereinafter referred to as the "first" heat exchanger plate, and the heat exchanger The plate 30 is hereinafter referred to as the "second" heat exchanger plate. The corresponding heat exchanger plates are also described in more detail in the accompanying figures. Only two corresponding heat exchanger plates 20 , 30 are marked with reference symbols, however all heat exchanger blocks 10 are built up entirely from corresponding heat exchanger plates 20 , 30 .

[0049] Not only in the first heat exchanger plate 20 but also in the second heat exchanger plate 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com