Method for preparing bone gelatin by ultrasonic assisted enzyme method

A technology of ultrasound and bone gelatin, applied in the field of gelatin preparation, can solve the problems of long enzymatic hydrolysis time, few enzymes, uneven raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

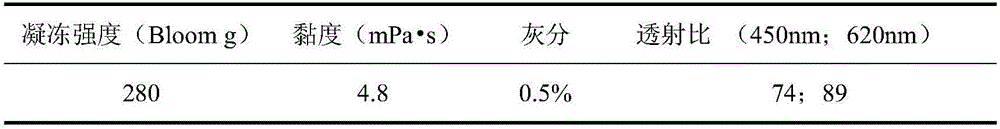

Examples

Embodiment 1

[0023] For specific implementation see figure 1 , the steps include:

[0024] (1) pulverizing the defatted bone particles into defatted bone powder with a particle size of ≤600 μm;

[0025] (2) 500 g of defatted bone powder with a particle size ≤ 600 μm obtained in step (1) was decalcified with 5 L of 0.5 molL hydrochloric acid for 12 hours, washed with water, and then separated into solid and liquid by a centrifuge;

[0026] (3) Add water to the decalcified bone powder obtained after the solid-liquid separation in step (2) and stir to obtain a slurry, then add hydrochloric acid to adjust the pH value of the slurry to 3, and add dry decalcified bone powder to the slurry with a pH value of 3 1‰ protease of the bone meal was subjected to enzymatic hydrolysis for 5 hours, and ultrasonic waves were applied at the same time of enzymatic hydrolysis. The ultrasonic power was 100W, and the ultrasonic time was 20 minutes.

[0027] (4) After step (3) enzymatic hydrolysis, the obtained...

Embodiment 2

[0032] For specific implementation see figure 1 , the steps include:

[0033] (1) pulverizing the defatted bone particles into defatted bone powder with a particle size of ≤600 μm;

[0034] (2) 500 g of defatted bone powder with a particle size ≤ 600 μm obtained in step (1) was decalcified with 5 L of 0.5 molL hydrochloric acid for 12 hours, washed with water, and then separated into solid and liquid by a centrifuge;

[0035] (3) Add water to the decalcified bone powder obtained after the solid-liquid separation in step (2) and stir to obtain a slurry, then add hydrochloric acid to adjust the pH value of the slurry to 3, and add dry decalcified bone powder to the slurry with a pH value of 3 1‰ protease of bone meal was subjected to enzymatic hydrolysis for 5 hours, and ultrasonic waves were applied at the same time of enzymatic hydrolysis. The ultrasonic power was 200W, and the ultrasonic time was 20 minutes.

[0036] (4) After step (3) enzymatic hydrolysis, the obtained slu...

Embodiment 3

[0041] The specific implementation is as follows:

[0042] (1) pulverizing the defatted bone particles into defatted bone powder with a particle size of ≤600 μm;

[0043] (2) 500 g of defatted bone powder with a particle size ≤ 600 μm obtained in step (1) was decalcified with 5 L of 0.5 molL hydrochloric acid for 2 hours, washed with water, and then solid-liquid separation was performed with a centrifuge;

[0044] (3) Add water to the decalcified bone meal obtained after the solid-liquid separation in step (2) and stir to obtain a slurry, then add hydrochloric acid to adjust the pH value of the slurry to 1.5, and add dry decalcified bone powder to the slurry with a pH value of 1.5 The 0.5% protease of the bone meal was subjected to enzymatic hydrolysis for 2 hours, and ultrasonic waves were applied at the same time. The ultrasonic power was 300 W, and the ultrasonic time was 20 minutes.

[0045] (4) After step (3) enzymatic hydrolysis, the obtained slurry is centrifuged to se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com