High-density gadolinium and tungsten borate scintillation glass and preparation method thereof

A technology of gadolinium tungsten borate and scintillation glass, applied in the field of luminescent materials, can solve the problem of low density of scintillation glass, and achieve the effects of short preparation period, improved luminous efficiency, and easy adjustment of chemical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Preparation process

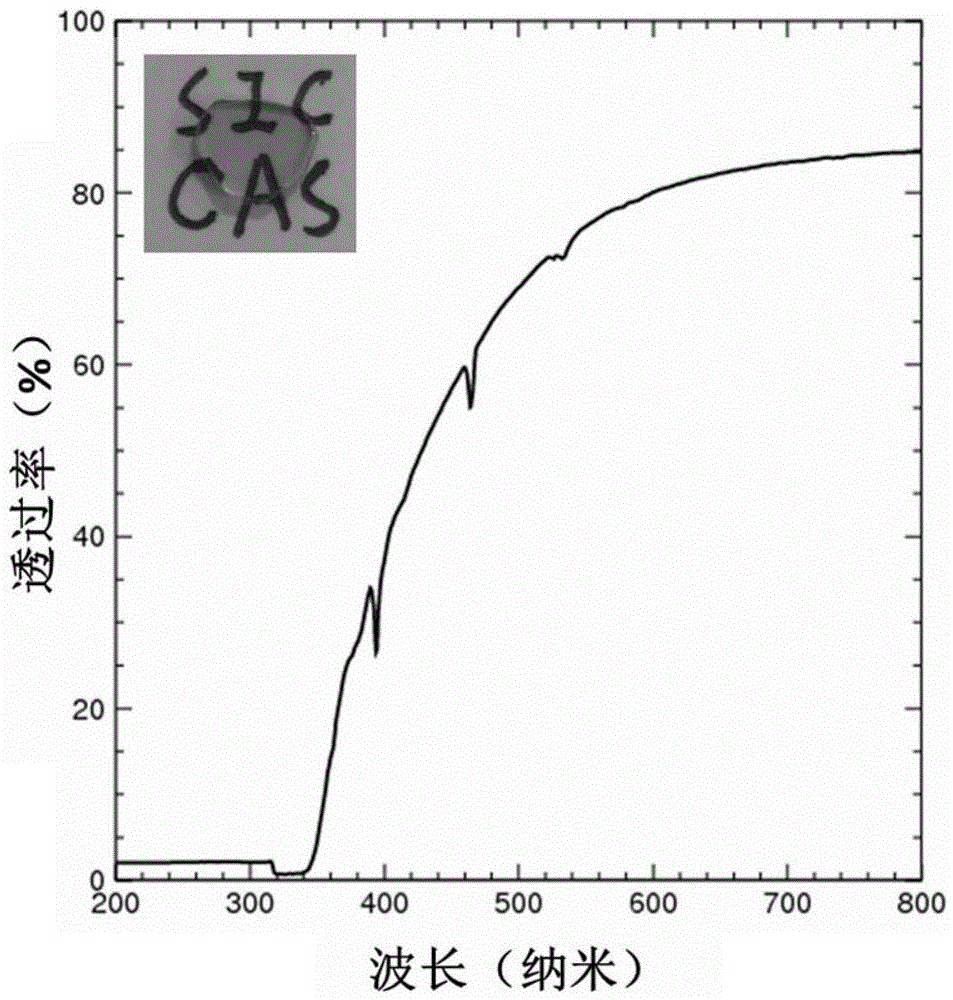

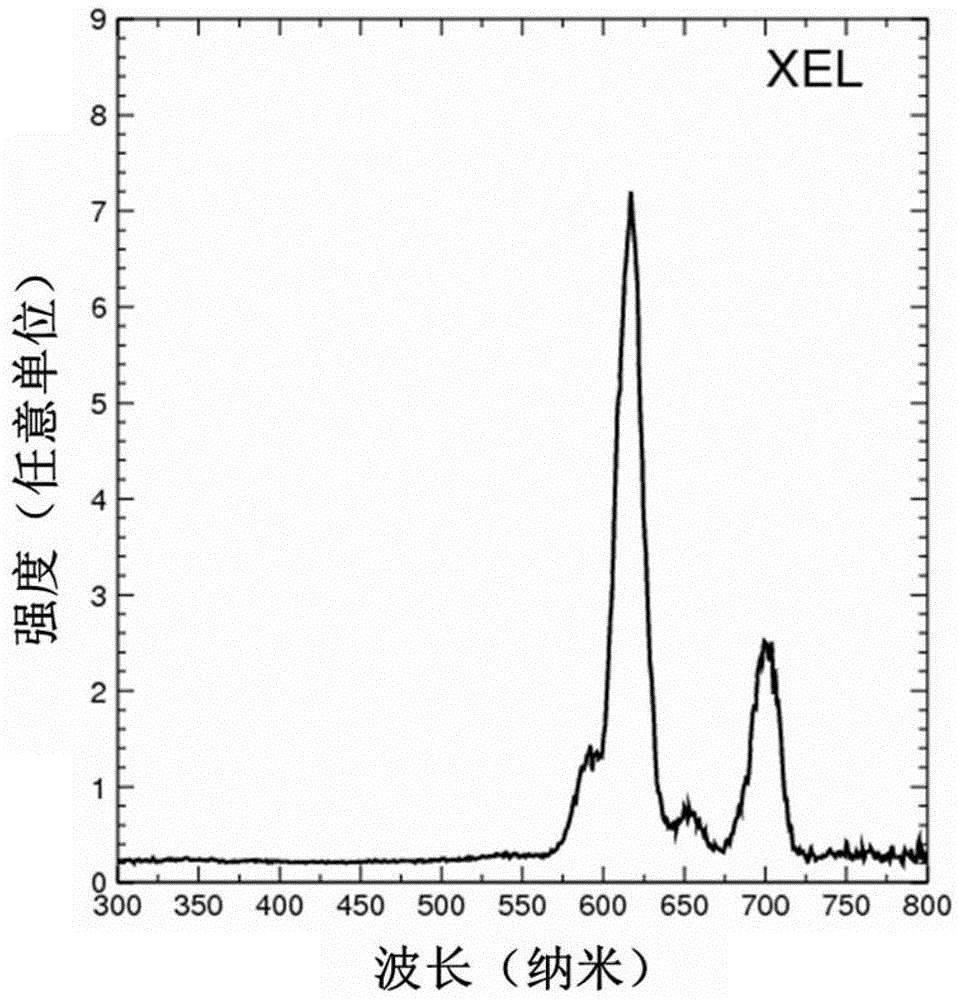

[0037] According to glass composition 20.5Gd 2 o 3 -47.5WO 3 -30B 2 o 3 -2Eu 2 o 3 (mol%) Accurately weigh the glass raw material, fully grind the glass raw material in an agate mortar for 15 minutes, pour the ground raw material into a platinum crucible, and put it in a high-temperature electric furnace at 1100°C for 30 minutes to obtain uniform glass melting. body. Then pour the above melt into an iron plate preheated to 300°C, and then use another iron plate to press it into shape, and quickly place the formed glass in a muffle furnace at 400°C for 1 hour for annealing treatment. The obtained scintillating glass primary product is processed into the scintillating glass of the present invention after cutting, surface grinding and polishing. Measured by the Archimedes method, the density of the glass is 6.19g / cm 3 . The transmittance of the invented scintillation glass is as figure 1 as shown, figure 1 Middle illustration is the phy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com