Wastewater centralized treatment system and method for toilet wastewater collectors of high-speed railway passenger cars

A high-speed railway, centralized treatment technology, applied in biological water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc. , technically reliable methods, etc., to achieve the effect of simultaneous short-range nitrification and denitrification and denitrification, and to improve biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

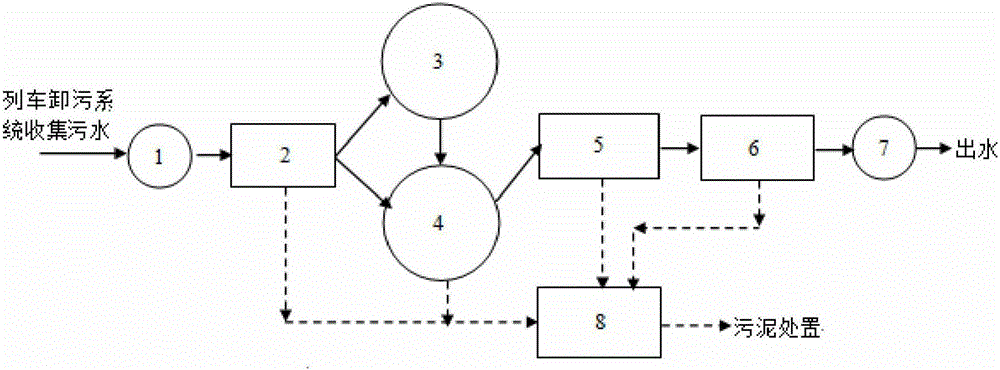

[0031] Embodiment 1: as figure 1 As shown, a kind of high-speed railway passenger car lavatory centralized sewage treatment system provided by the present invention mainly consists of a rotating drum grille, a pretreatment adjustment tank, an internal circulation micro-aerobic reactor, an internal circulation anaerobic reactor, and a double-circulation aerobic reaction device, special denitrification aeration filter, disinfection facilities, sludge treatment device, automatic control system and various pipelines, valves, pumps, etc.

[0032] A centralized sewage treatment system for high-speed railway passenger car toilet collectors. The sewage from the toilet collectors enters the rotating drum grille 1, and the back of the rotating drum grille 1 is connected to the pretreatment adjustment pool 2. The pretreatment adjustment pool 2 is connected to the internal circulation micro-oxygen reactor 3 and the internal The circulation anaerobic reactor 4 is connected, the internal ci...

Embodiment 2

[0035] Embodiment 2: as figure 1 As shown, the high-speed railway passenger car lavatory sewage centralized treatment system and method of the present invention, the rotating drum grille is used to remove toilet paper, large pieces of feces, etc. in the lavatory sewage;

[0036]Since the water quality and volume of high-speed rail passenger car toilet sewage vary greatly, and the content of suspended solids, ammonia nitrogen and phosphorus in the water is high, in order to ensure the stability of the subsequent treatment process, a pretreatment adjustment tank with bleaching powder is set up to effectively remove part of the ammonia nitrogen in the sewage , phosphorus and suspended solids, and ensure the stability of sewage water quality and water quantity;

[0037] The settings of internal circulation microaerobic reactor, internal circulation anaerobic reactor and double circulation aerobic reactor can efficiently remove nitrogen and improve the biodegradability of sewage; ...

Embodiment 3

[0043] Embodiment 3: as figure 1 Shown, a kind of high-speed railway passenger car lavatory sewage centralized treatment method comprises the following steps;

[0044] Step 1. The sewage from the toilet collector of the high-speed railway passenger car first passes through the rotating drum grille 1 to remove toilet paper, large pieces of feces, etc. in the sewage from the toilet collector;

[0045] Step 2, then enter the pretreatment adjustment tank 2, remove part of the ammonia nitrogen and suspended solids in the sewage, and adjust the water quality and water quantity;

[0046] Step 3, the effluent from the pretreatment adjustment tank 2 enters the internal circulation microaerobic reactor 3 and the internal circulation anaerobic reactor 4 respectively; the effluent from the internal circulation microaerobic reactor 3 enters the internal circulation anaerobic reactor 4; the internal circulation microaerobic reaction Reactor 3 realizes short-range nitrification through gran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com