Cold rolling method for high-magnetic-induction grain-oriented silicon steel in extremely thin specification

A technology of high magnetic induction orientation and cold rolling method, which is applied in metal rolling and other directions, can solve the problems of poor plate shape and low rolling efficiency of high-end silicon steel, prevent brittle broken strips, have good surface quality, and solve the problem of plate shape bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The high magnetic induction grain-oriented silicon steel with 3.21% Si is rolled by Sendzimir 20-high rolling mill. The specific steps and control parameters are as follows:

[0031] 1) Smelting, continuous casting, and hot rolling follow the production method of conventional high magnetic induction oriented silicon steel, and the thickness of the silicon steel coil is 2.3mm before cold rolling, and normalized pickling is carried out;

[0032] 2) Adopt one-time cold rolling method to carry out continuous reversible seven-pass cold rolling:

[0033] 2.1) The first five passes use rough surface work rolls (Φ65mm), and the surface roughness of the work rolls is controlled at 1.7μm; the last two passes use fine surface work rolls (Φ66mm), and the surface roughness of the work rolls is controlled at 0.22μm;

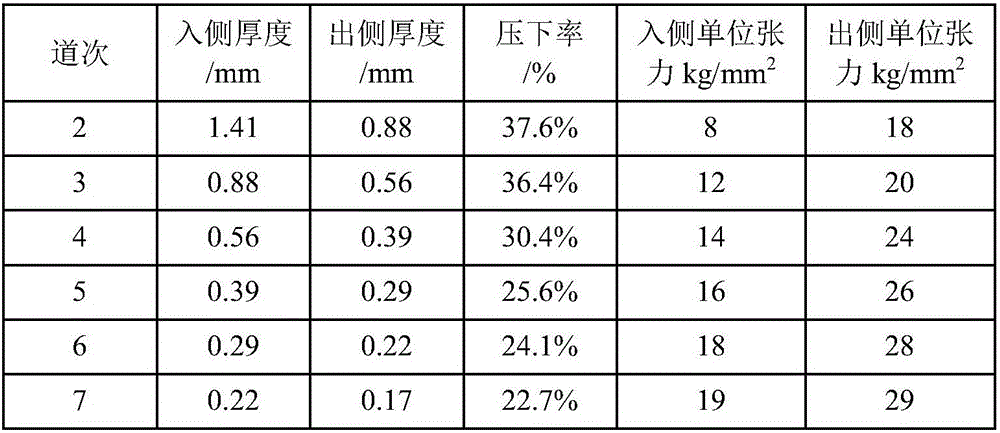

[0034] 2.2) Control the reduction rate at 18% to 44%, among which, the reduction rate of the first pass is 38.7%, the reduction rate of the last pass is 22.7%, and the ...

Embodiment 2

[0044] The high magnetic induction grain-oriented silicon steel with 3.21% Si is rolled by Sendzimir 20-high rolling mill. The specific steps and control parameters are as follows:

[0045] 1) Smelting, continuous casting, and hot rolling follow the production method of conventional high magnetic induction oriented silicon steel, and the thickness of the hot-rolled silicon steel coil is 2.3mm before cold rolling, and normalized pickling is carried out;

[0046] 2) Adopt one-time cold rolling method to carry out continuous reversible seven-pass cold rolling:

[0047] 2.1) The rough surface work roll (Φ66mm) is used in the first five passes and the surface roughness of the work roll is controlled at 1.8μm; the fine surface work roll (Φ65mm) is used in the last two passes, and the surface roughness of the work roll is controlled at 0.24μm;

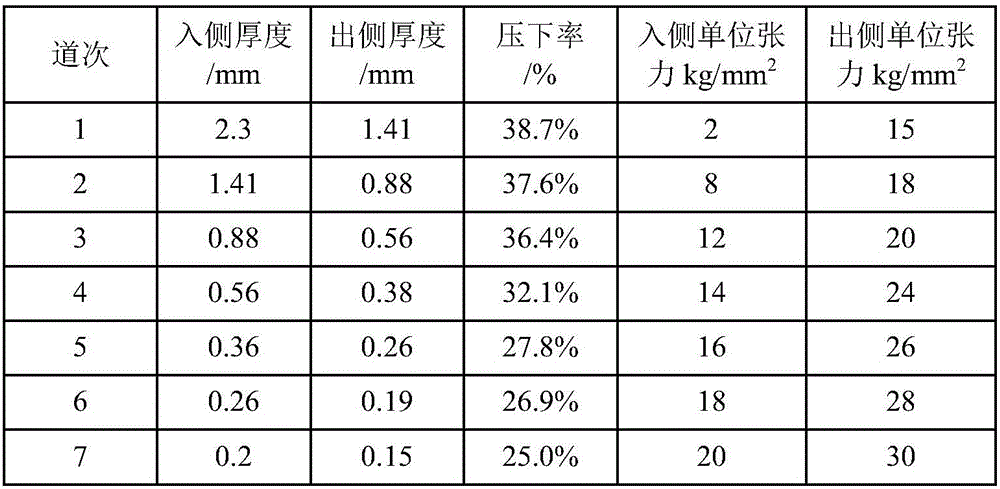

[0048] 2.2) The reduction rate is controlled at 25.0% to 38.7%, among which, the reduction rate of the first pass is 38.7%, the reduction rate...

Embodiment 3~6

[0059] The high magnetic induction grain-oriented silicon steel with 3.21% Si is rolled by Sendzimir 20-high rolling mill. The specific steps and control parameters are as follows:

[0060] 1) Smelting, continuous casting, and hot rolling follow the production method of conventional high magnetic induction oriented silicon steel, and the thickness of the steel coil is 2.0mm-2.5mm before cold rolling, and normalized pickling is carried out;

[0061] 2) Adopt one-time cold rolling method to carry out continuous reversible seven-pass cold rolling:

[0062] 2.1) The first five passes use rough-faced work rolls, and the surface roughness of the work rolls is controlled at 1.5-1.8 μm; the last two passes use fine-faced work rolls, and the surface roughness of the work rolls is controlled at 0.15-0.25 μm;

[0063] 2.2) Control the reduction rate of the first pass at 30% to 45%, control the reduction rate of the last pass at 18% to 31%, and control the reduction rate of the remaining ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com