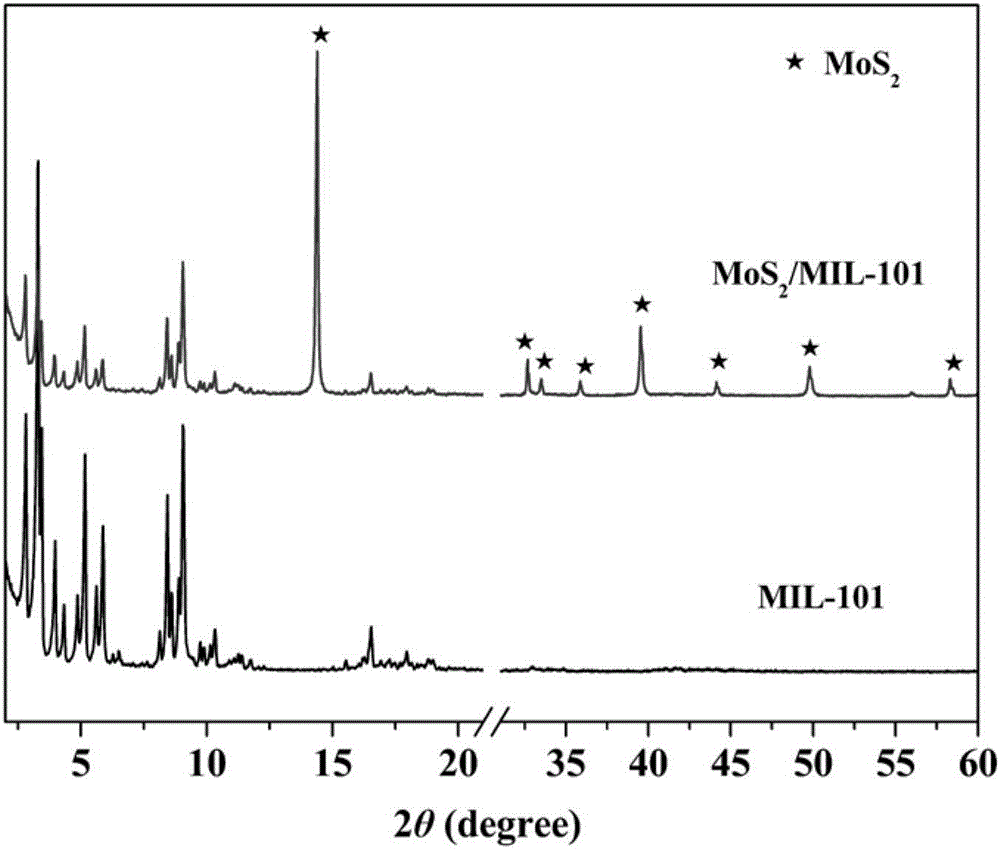

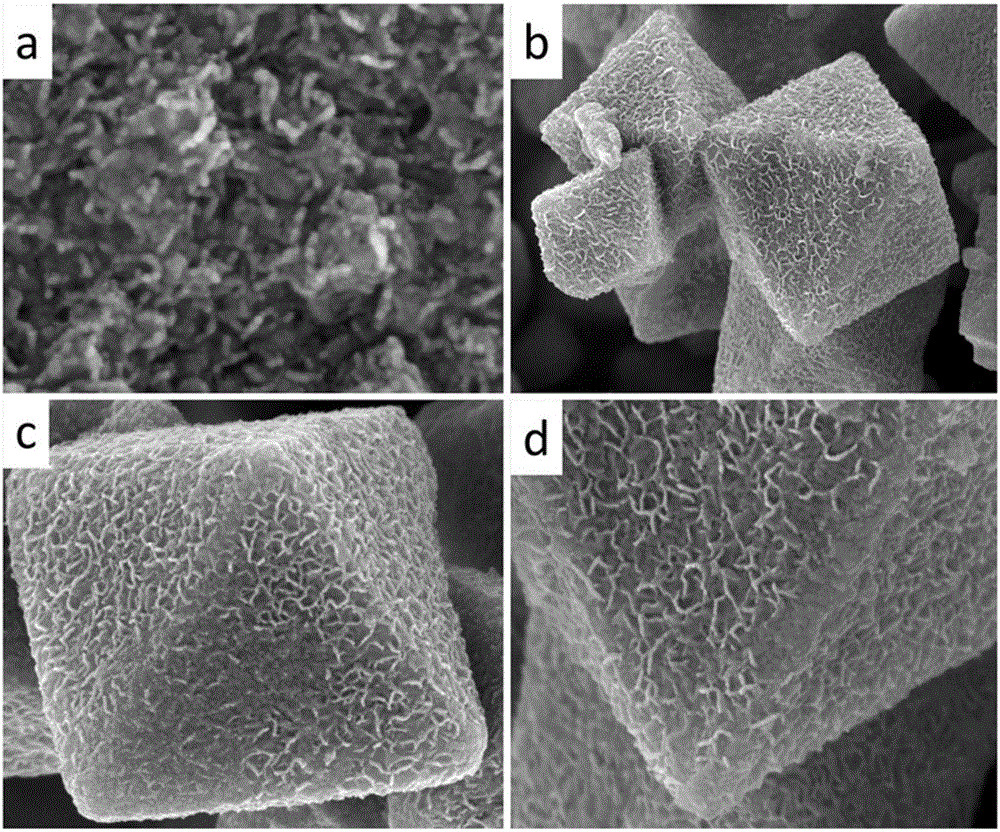

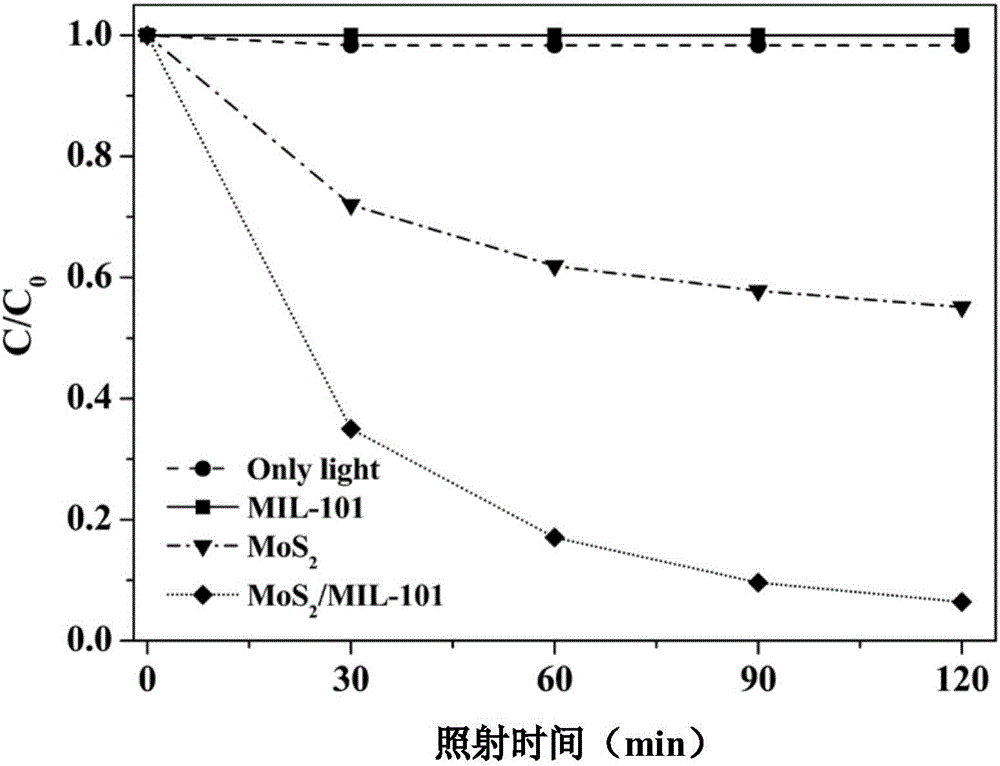

Molybdenum disulfide/MIL-101 composite photocatalyst material as well as preparation method and application thereof

A technology of composite photocatalysis and molybdenum disulfide, which is applied in the field of photocatalytic materials, can solve the problems of reducing photocatalytic activity and poor electrical conductivity, and achieves the effects of easy operation, low equipment requirements and huge specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Weigh 1.004g chromium nitrate and 0.412g terephthalic acid, measure 0.109mL hydrofluoric acid, mix and dissolve in 12mL water, and stir evenly;

[0032] (2) Transfer the mixed solution obtained in step (1) to a 25mL stainless steel reaction kettle, put it in an oven and react at 220°C for 8h, and then naturally cool to room temperature;

[0033] (3) Rinse the reaction product obtained in step (2) twice with water and ethanol, purify, filter, and finally dry the product in a vacuum oven at 150°C overnight to obtain MIL-101;

[0034] (4) Take by weighing 40mg sodium molybdate and 80mg thioacetamide respectively, be dissolved in water, stir evenly;

[0035] (5) Add 40 mg of MIL-101 powder to the mixed solution obtained in step (4), and magnetically stir for 7 hours to obtain a sodium molybdate / thioacetamide / MIL-101 dispersion;

[0036] (6) Transfer the dispersion obtained in step (5) to a 25mL stainless steel reaction kettle, put it in an oven and react at 200°C for 2...

Embodiment 2

[0039] (1) Weigh 2.007g chromium nitrate and 0.823g terephthalic acid, measure 0.217mL hydrofluoric acid, mix and dissolve in 24mL water, and stir evenly;

[0040] (2) Transfer the mixed solution obtained in step (1) to a 50mL stainless steel reaction kettle, put it into an oven and react at 220°C for 8h, and then naturally cool to room temperature;

[0041] (3) Rinse the reaction product obtained in step (2) twice with water and ethanol, purify, filter, and finally dry the product in a vacuum oven at 150°C overnight to obtain MIL-101;

[0042] (4) Take by weighing 30mg sodium molybdate and 60mg thioacetamide respectively and dissolve in water, stir evenly;

[0043] (5) Add 20 mg of MIL-101 powder to the mixed solution obtained in step (4), and magnetically stir for 5 hours to obtain a sodium molybdate / thioacetamide / MIL-101 dispersion;

[0044] (6) Transfer the dispersion obtained in step (5) to a 25mL stainless steel reaction kettle, put it in an oven and react at 180°C for ...

Embodiment 3

[0047] (1) Weigh 3.011g of chromium nitrate and 1.235g of terephthalic acid, measure 0.326mL of hydrofluoric acid, mix and dissolve in 36mL of water, and stir evenly;

[0048] (2) Transfer the mixed solution obtained in step (1) to a 50mL stainless steel reaction kettle, put it in an oven and react at 220°C for 8h, and then naturally cool to room temperature;

[0049] (3) Rinse the reaction product obtained in step (2) twice with water and ethanol, purify, filter, and finally dry the product in a vacuum oven at 150°C overnight to obtain MIL-101;

[0050] (4) Take by weighing 67.5mg sodium molybdate and 135mg thioacetamide respectively and dissolve in water, stir evenly;

[0051] (5) Add 30 mg of MIL-101 powder to the mixed solution obtained in step (4), and magnetically stir for 8 hours to obtain a sodium molybdate / thioacetamide / MIL-101 dispersion;

[0052] (6) Transfer the dispersion liquid obtained in step (5) to a 25mL stainless steel reaction kettle, put it in an oven and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com