Catalyst, preparation method thereof and application in preparation of oxalate

A catalyst and oxalate technology, which is applied in the direction of catalyst activation/preparation, carbon monoxide or formate reaction preparation, chemical instruments and methods, etc., can solve the problems of high loading capacity and increased catalyst cost, and achieve improved performance and small size. , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1 Catalyst sample preparation

[0051] Preparation of graphene nanosheets

[0052] A two-electrode system is adopted, with high-purity graphite paper as the anode and cathode, followed by cleaning with 0.1mol / L hydrochloric acid, acetone, ethanol, and ultrapure water; 1mol / L ammonium sulfate solution as the electrolyte. Using the square wave potentiometric method, the upper limit is 9V, the lower limit is -9V, and the frequency is 10 Hz, the graphite electrode is electrolyzed, and the graphene nanosheet suspension is obtained through sulfate radical intercalation expansion and stripping, and the graphene nanosheet suspension is ultrasonically filtered, washed, After vacuum drying, graphene nanosheets are obtained, which are denoted as GNPs.

[0053] Preparation of nitrogen-doped graphene nanosheets

[0054] The above-mentioned graphene nanosheet GNP obtained is placed in a tube furnace, and at nitrogen doping temperature, feeds ammonia gas for a period ...

Embodiment 2

[0066] Example 2 Sample Characterization

[0067] The nitrogen doping amount in the nitrogen-doped graphene nanosheet samples N-GNP-1-N-GNP-3 was measured by XPS, and the results are shown in Table 1.

[0068] The loading capacity of palladium in the catalyst samples CAT-1 to CAT-7 was measured by ICP, and the results are shown in Table 2.

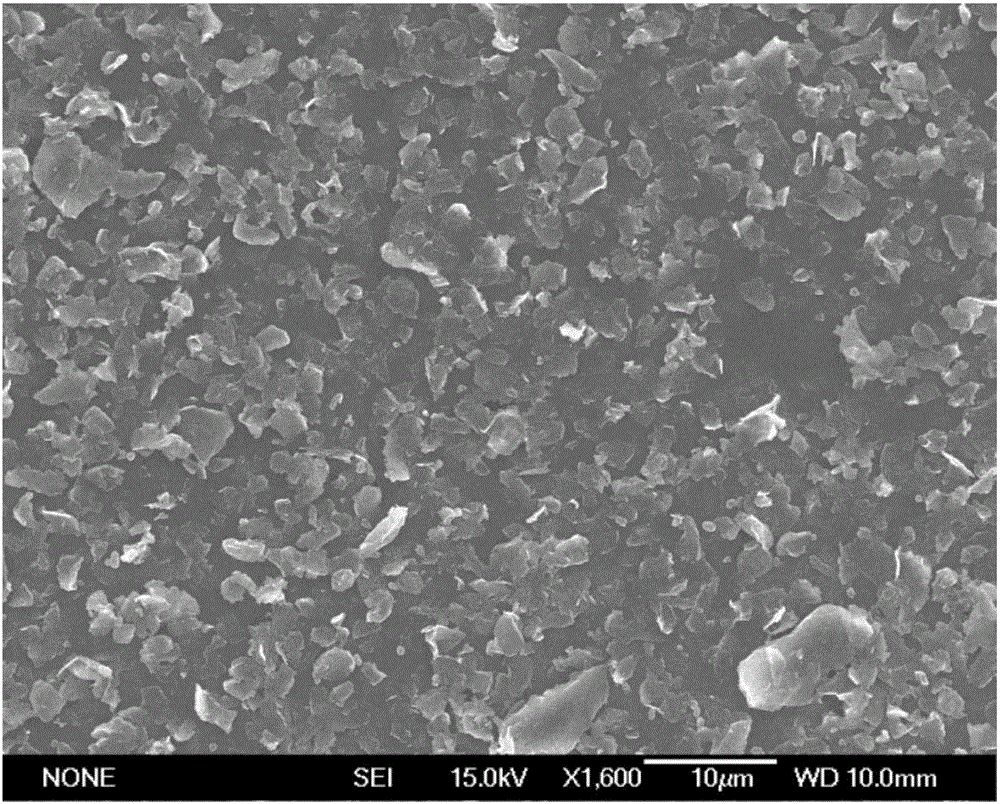

[0069] Scanning electron micrographs of graphene nanosheets GNPs such as figure 1 As can be seen from the figure, GNP is a nanosheet with a thickness of 0.8-30 nm and a size of 1-15 μm.

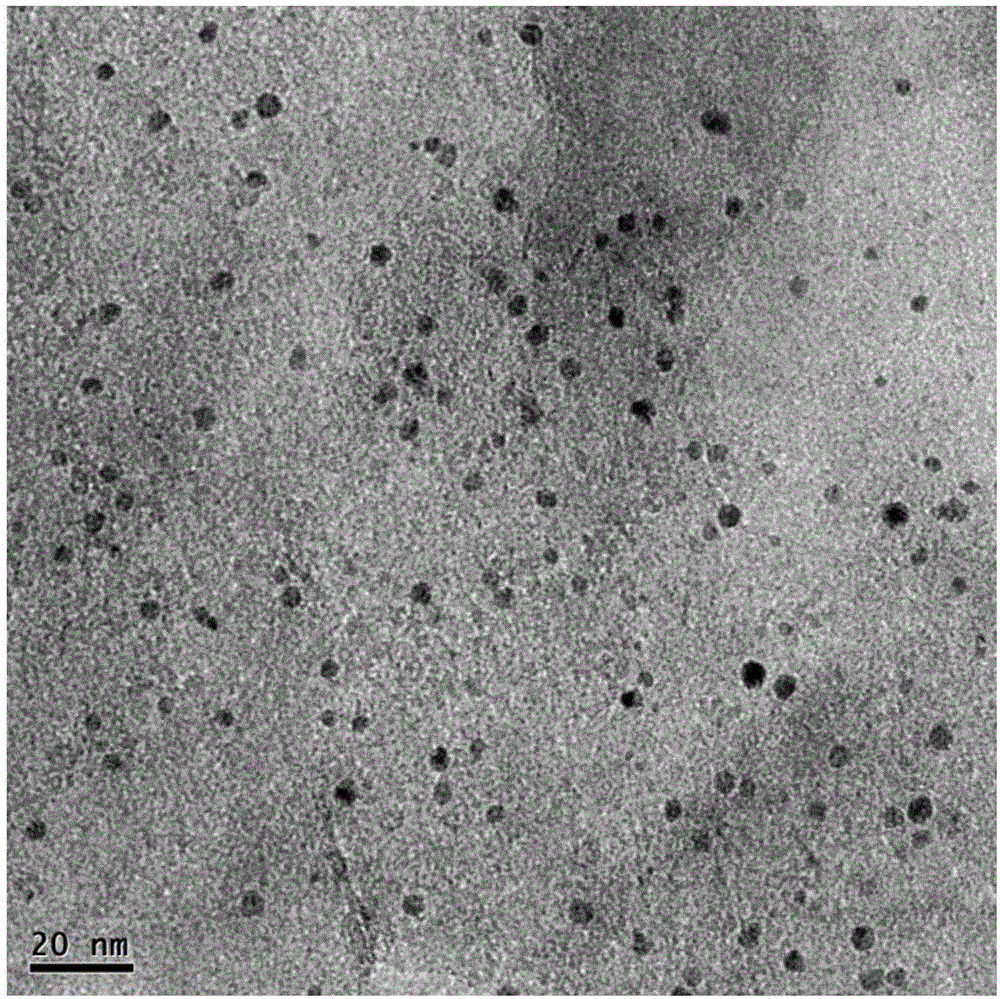

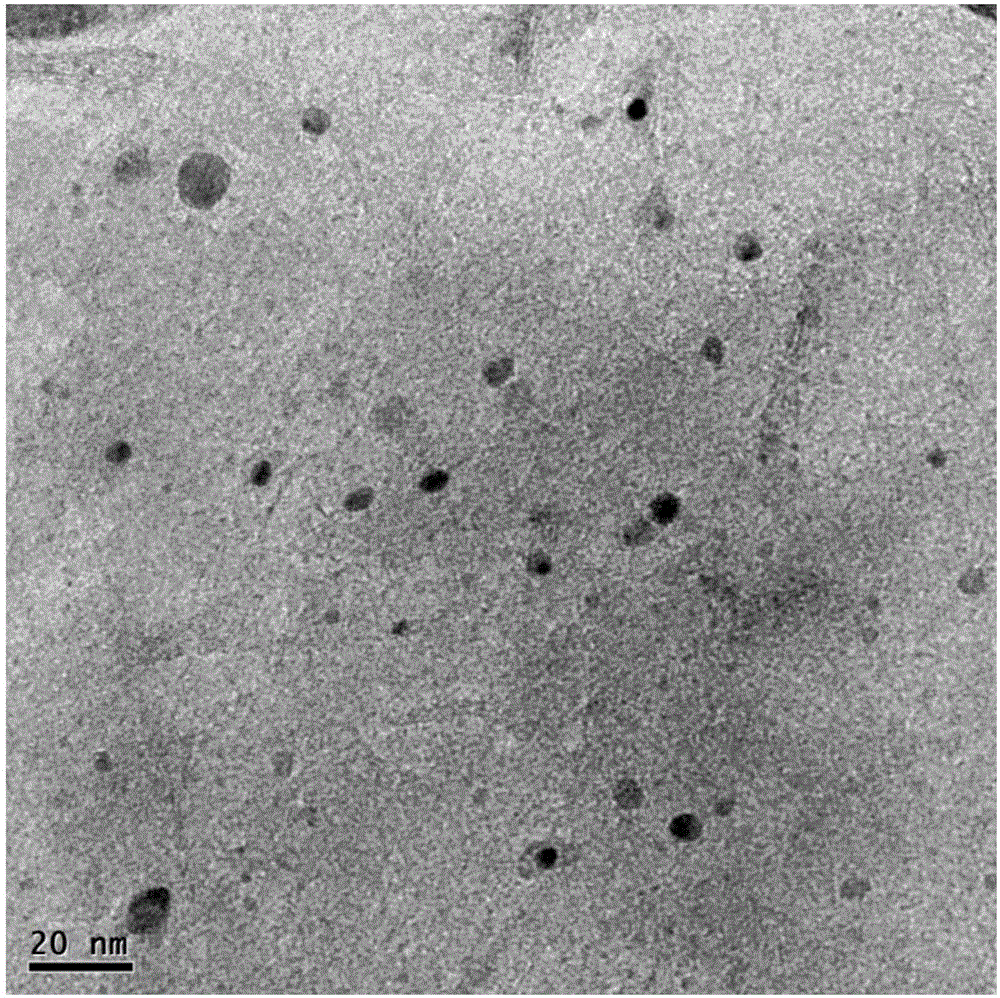

[0070] Catalyst samples CAT-1~CAT-7 were characterized by transmission electron microscopy. The results showed that nitrogen doping greatly improved the dispersion of active component palladium. Taking sample CAT-1 as a typical representative, its transmission electron microscope pictures are as follows figure 2 shown by figure 2 It can be seen that palladium nanoparticles are highly dispersed on the surface of nitrogen-doped graphene nanosheets, an...

Embodiment 3

[0072] Embodiment 3 catalyst sample is used for the reaction evaluation of preparing oxalic acid ester

[0073] The catalyst samples CAT-1~CAT-7 and the comparative sample Pd / GNP were respectively placed in a fixed-bed reactor and applied to the gas-phase oxidative coupling of CO to prepare oxalate. The raw material gas included CO and methyl nitrite. The flow volume ratio of CO and methyl nitrite is 1.4, and the gas phase space velocity of the feed gas is 3L g -1 h -1 , the reaction temperature was 130°C, and the reaction pressure was 0.1Mpa. The feed gas and products were monitored and analyzed by on-line gas chromatography. The reaction results are shown in Table 3.

[0074] table 3

[0075]

[0076] As can be seen from the data in Table 3, compared with the catalyst sample provided by the technical solution of the present application, when the palladium loading is similar (compared with CAT-4), the comparative example sample has a single-pass conversion rate of CO far...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com