Preparation method of platinum-nickel alloy nanocluster and fuel cell using it

A platinum-nickel alloy and nano-cluster technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of unfavorable large-scale promotion of fuel cells, unsatisfactory catalytic activity of catalysts, low stability, etc., to avoid pollution and Effect of energy consumption, improving electronic structure of Pt metal surface, and reducing fabrication cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

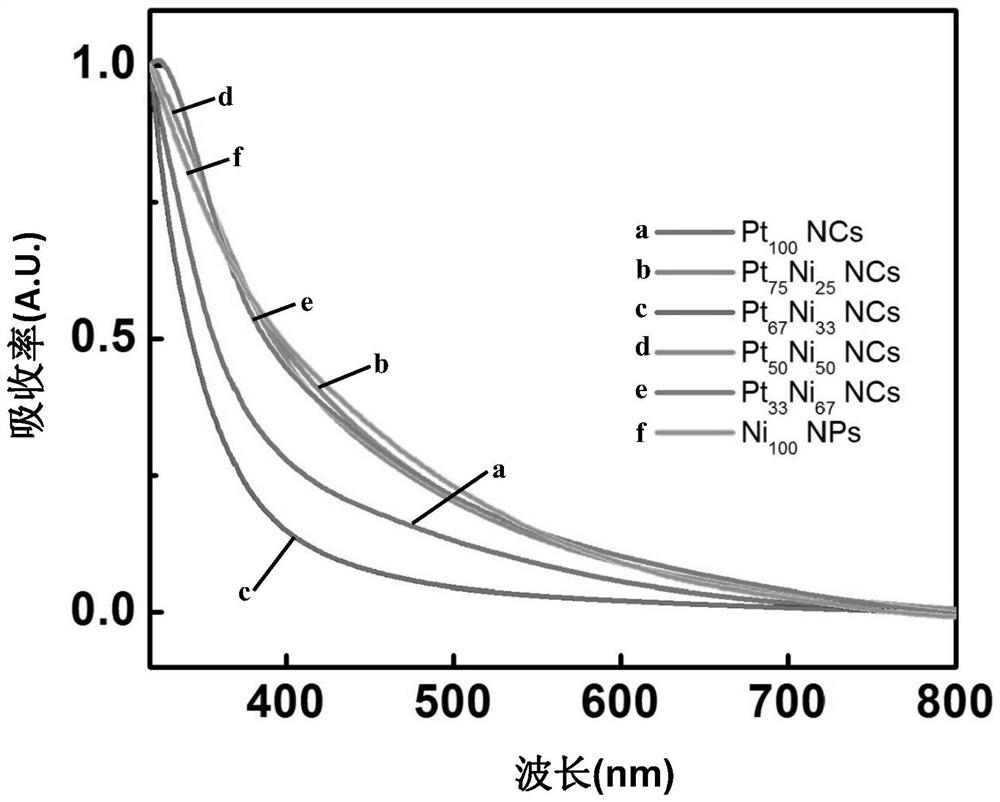

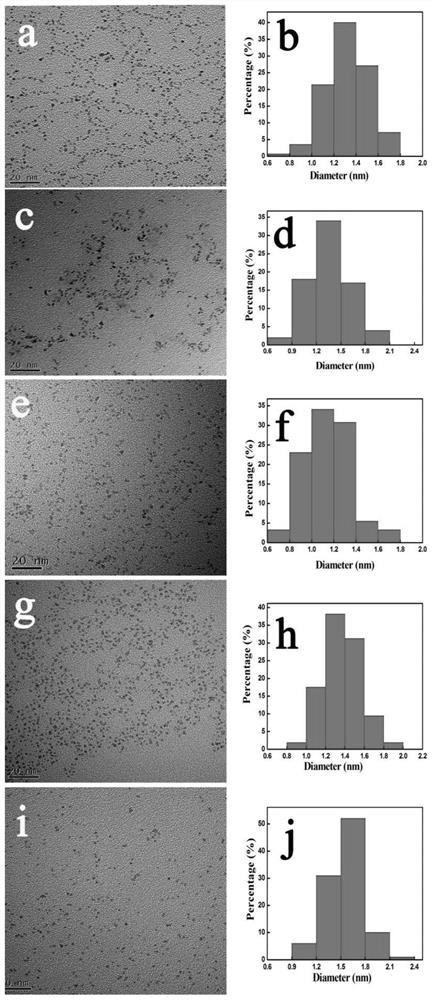

[0046] According to the molar ratio of platinum to nickel element 2:1, weigh 0.4006g of PVP (K-30) and 19.80mg of nickel chloride hexahydrate into a 100mL three-necked flask, add 60mL of ethylene glycol, heat to 80°C, and stir 30min.

[0047] Cool down to about 5°C, add 8.33mL of chloroplatinic acid hexahydrate solution, adjust the pH to 9 with NaOH (1mol / l), heat to 198°C, keep stirring and condense and reflux for 3h to obtain platinum-nickel alloy nanoclusters ( Pt 67 Ni 33 NCs) catalyst.

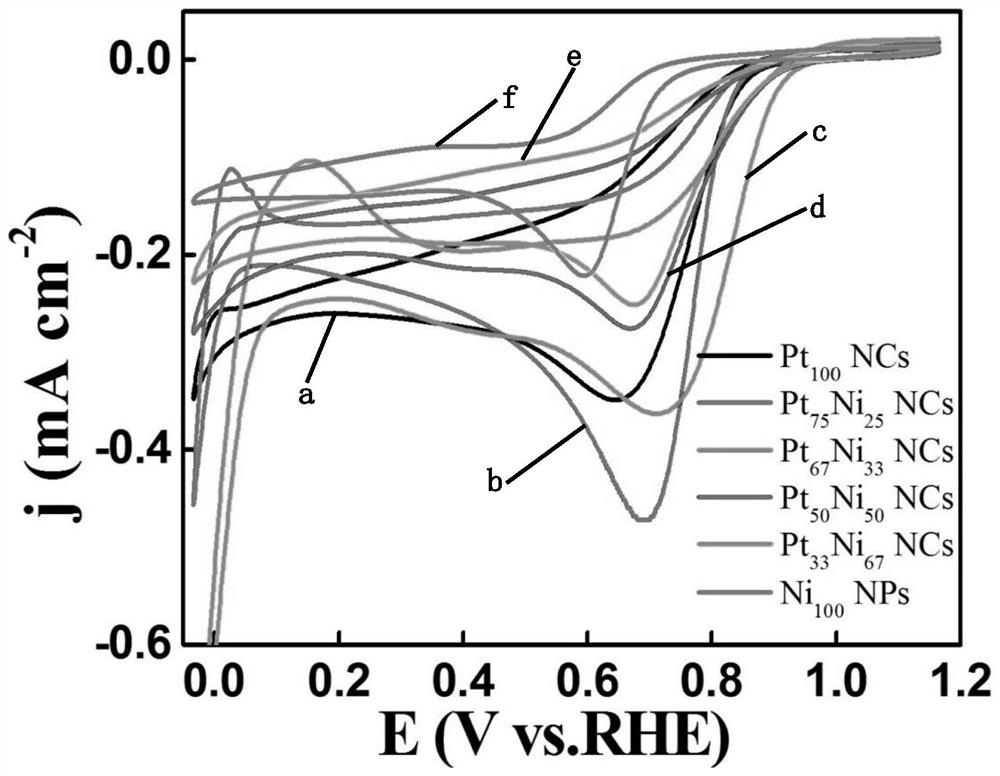

[0048] Catalytic performance test:

[0049] The electrochemical test and characterization was carried out in a test cell with a three-electrode system on a CHI 750E electrochemical workstation produced by Shanghai Chenhua Company. Among them, the platinum wire is the counter electrode, the Ag / AgCl electrode is the reference electrode, and the glassy carbon electrode loaded with the catalyst is the working electrode. Weigh 2 mg of the catalyst into 1.0 mL of ethanol solution, add 10 μ...

Embodiment 2

[0057] According to the molar ratio of platinum to nickel element 1:0, weigh 0.4006g of PVP (K-30) into a 100mL three-neck flask, add 60mL of ethylene glycol, heat to 80°C, and stir for 30min.

[0058] Cool down to about 2°C, add 8.33mL of chloroplatinic acid hexahydrate solution, adjust the pH to 10 with NaOH (1mol / l), heat to 180°C, keep stirring and reflux for 3h to obtain (Pt 100 NCs) catalyst.

Embodiment 3

[0060] According to the molar ratio of platinum to nickel element 3:1, weigh 0.4006g of PVP (K-30) and 14.86mg of nickel chloride hexahydrate in a 100mL three-necked flask, add 60mL of ethylene glycol, heat to 80°C, stir 30min.

[0061] Cool down to about 3°C, add 9.37mL chloroplatinic acid hexahydrate solution, adjust the pH to 11 with NaOH (1mol / l), heat to 200°C, keep stirring and condense and reflux for 3h to obtain platinum-nickel alloy nanoclusters ( Pt 75 Ni 25 NCs) catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com