Screw compressor for mixed refrigeration field and application method thereof

The technology of a screw compressor and its application method, which is applied in the field of screw compressors, can solve problems such as short maintenance period, high noise frequency, and large cooling water consumption, and achieve the effects of convenient operation and maintenance, good dynamic balance, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

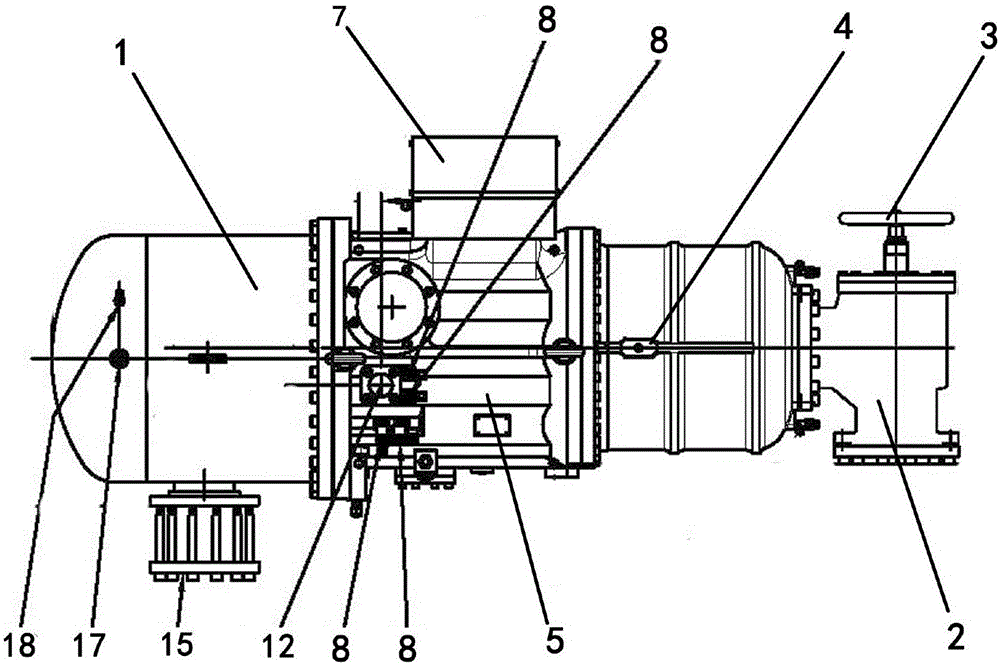

[0026] Such as figure 1 , figure 2 As shown, the screw compressor for mixed refrigerant compression includes a body 1, on which a cylinder 2, a piston 3, a connecting rod 4, and a body compression chamber 5 are installed, and the connecting rod 4 and the piston 3 are firmly connected to the body 1 Above, the suction inlet flange 6 is provided on the cylinder 2, and the junction box 7 is provided on the outer wall of the compression chamber 5 of the body. device 10, injection port 11 of the mechanical compression chamber, cleaning hole cover flange, and oil drain valve, the capacity regulating solenoid valve 8 is connected to the economizer interface 12, and the side of the mechanical filter 9 is provided with an oil level sight glass 13 and An oil balance valve 14; a horizontal check valve is installed on one side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com