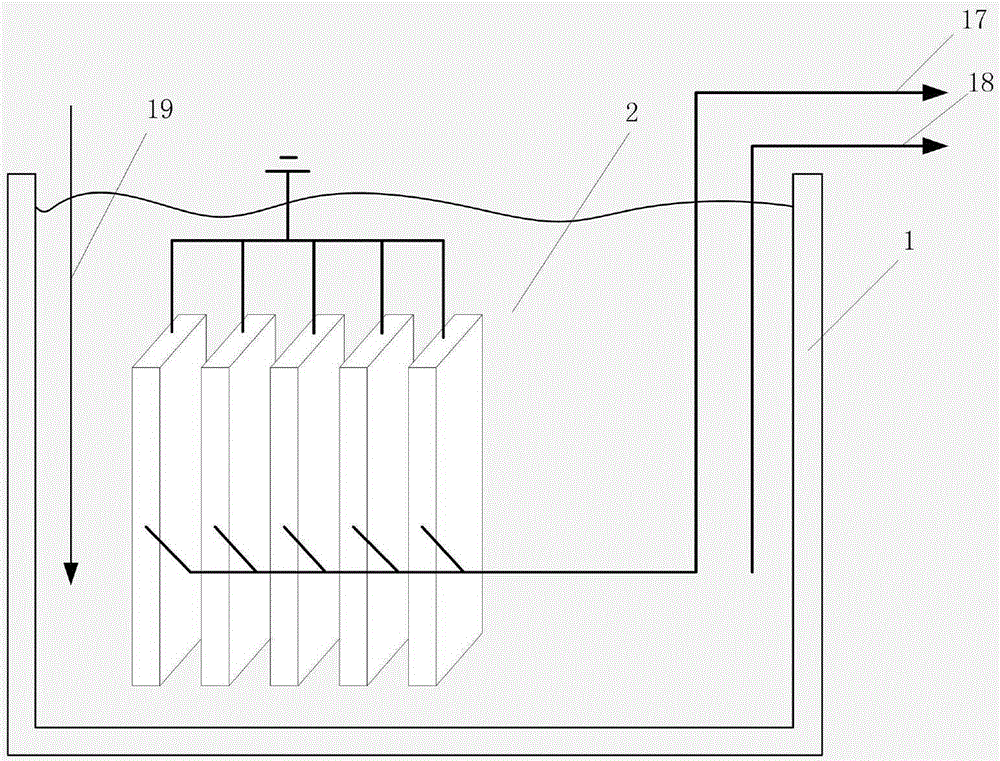

Flat sheet membrane pool using novel DEP electrode and membrane concentration system

A flat membrane, electrode plate technology, applied in separation methods, dispersed particle separation, etc., can solve problems such as hindering widespread use, unsuitable industrial conditions, pH value changes, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

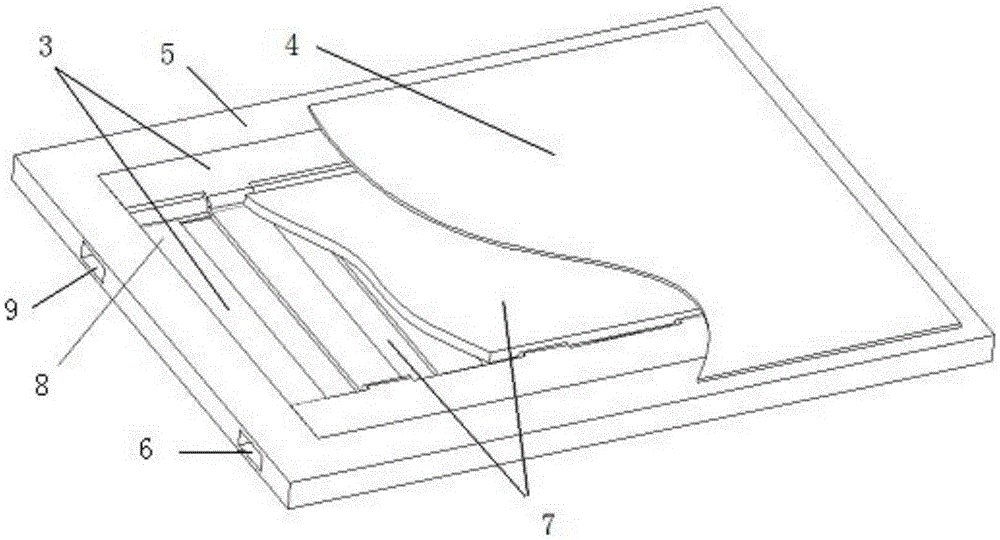

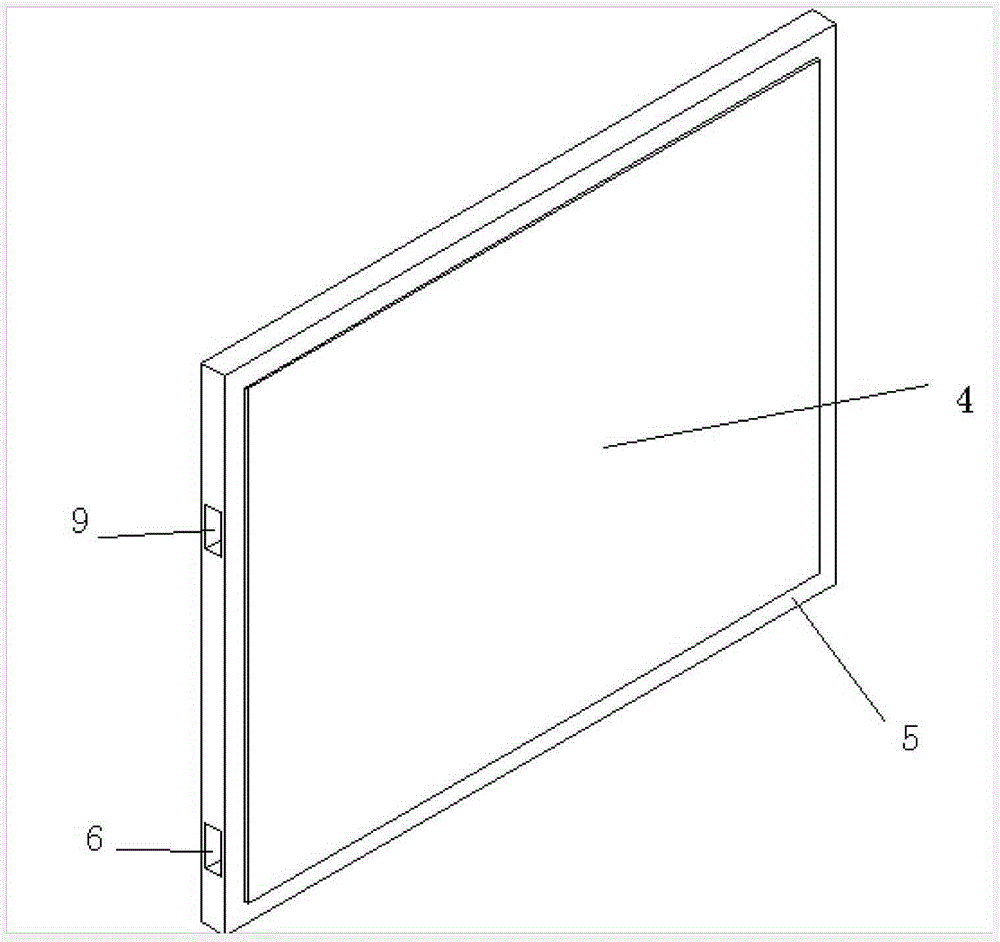

Embodiment 1

[0048] The sheet metal electrode assembly 3 includes two electrode plates insulated from each other. The electrode plate is a sheet metal part directly cut or stamped on a thin metal plate, including a plurality of electrodes arranged in a flat shape and one or more lines connecting all electrodes at the same time. The two electrode plates are stacked alternately, so that the electrodes of one electrode plate are placed in the space between two adjacent electrodes of the other electrode plate, and the two electrode plates are connected to different AC power sources through the power adapter 6 provided on the flat frame 5 The output terminal forms an electrode group, which generates a non-uniform electric field around it. The two electrode plates can be both insulated, or one can be insulated and the other can be a bare electrode; when one electrode plate is a bare electrode, the electrode plate should be made of corrosion-resistant materials, or undergo corrosion-resistant trea...

Embodiment 2

[0053] like Figure 9 As shown, the difference from Embodiment 1 is that the two electrode plates are grid-shaped electrode plates 25, which are composed of a plurality of electrodes 26 arranged in parallel and two edge lines 27 connecting the two ends of the electrodes. Two grid-shaped electrode plates are stacked at intervals to form an electrode group. Between the side lines 27 of the two grid-shaped electrode plates 25, an insulating sheet is used to stack them at intervals. When two grid-shaped electrode plates 25 are overlapped to form a sheet metal DEP electrode structure, the insulating sheet is arranged between the side lines 27 of the two grid-shaped electrode plates 25, so as to prevent the side lines 27 of the grid-shaped electrode plates 25 from touching , because the two ends of the electrode 26 are connected together by the side line 27, so the position of the electrode is relatively fixed during installation, and no later adjustment is required.

Embodiment 3

[0055] like Figure 10 As shown, the difference from Embodiment 2 is that the two electrode plates are three-dimensional grid-shaped electrode plates 28, and the three-dimensional grid-shaped electrode plates 28 are composed of a plurality of electrodes 29 arranged in parallel and two side lines 30 connecting the two ends of the electrodes. After the two ends of the electrode 29 are bent toward the same side, they are connected to two side lines respectively. The preferred way is: after the two ends of the electrode 29 are bent in a direction perpendicular to the electrodes, they are then bent 90° in a direction parallel to the electrodes 29 to form a stepped shape, so that the middle of the electrode 29 protrudes relative to the two ends. like Figure 11 , Figure 12 As shown, the edge parts of the two three-dimensional grid-shaped electrode plates 28 are stacked at intervals, and the electrodes 29 of the two three-dimensional grid-shaped electrode plates 28 are stacked alt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com