Gas diverting type boiler

A gas splitting and boiler technology, applied in the boiler field, can solve air pollution and other problems, and achieve the effects of eliminating pollution, saving costs, and achieving great social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

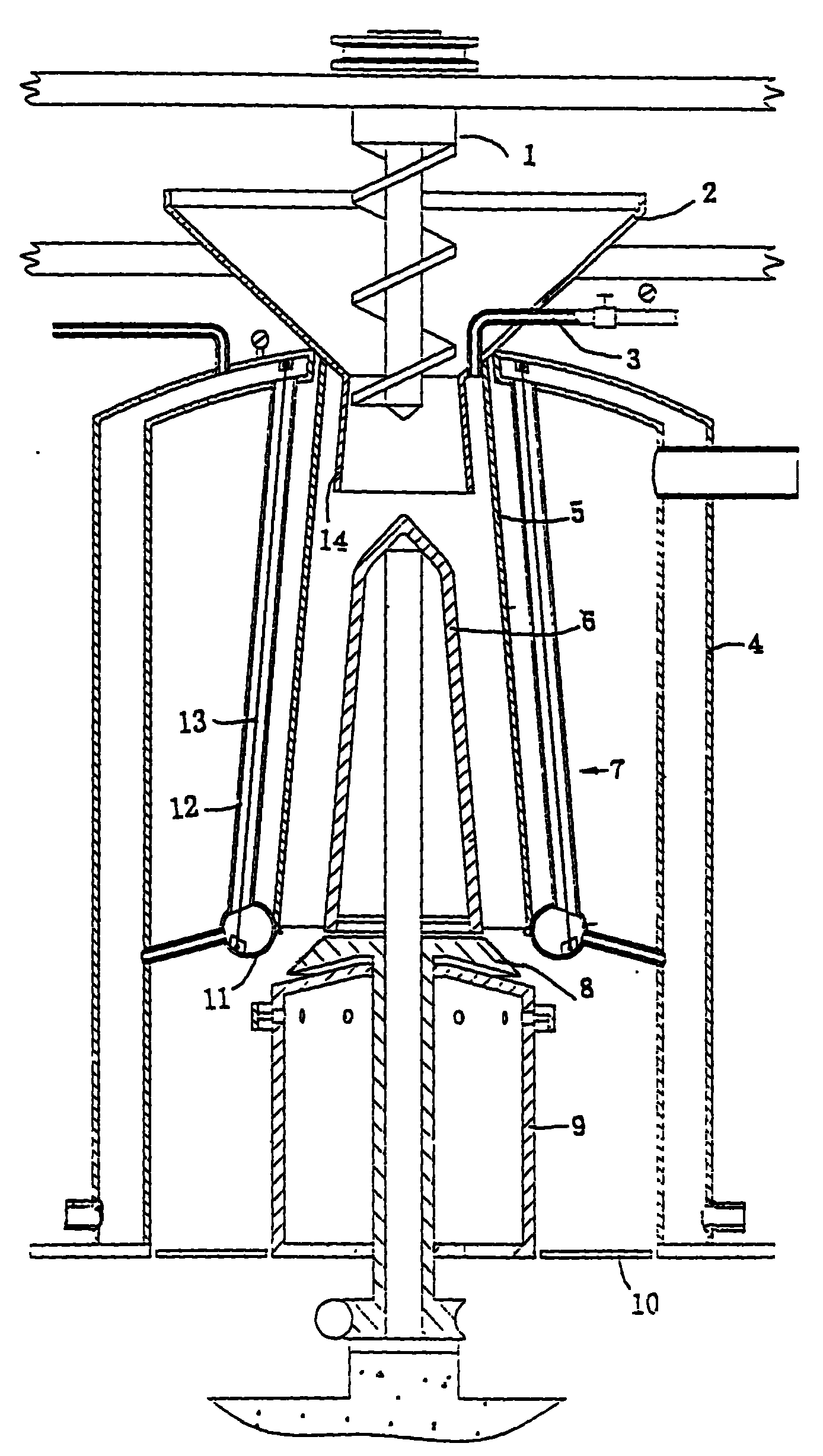

[0022] see figure 1 , the gas split boiler according to the present invention includes a boiler main body 4, a funnel-shaped coal bunker 2 is arranged on the top of the main body 4, and a conical carbonization chamber connected to the discharge port of the coal bunker 2 and whose lower end is close to the combustion layer of the furnace The tube 5 is provided with a fractionating cone 6 inside the distillation tube 5, and the space between the two forms a dry distillation chamber. A rotating coke pusher 8 and an air chamber 9 arranged below the coke pusher 8 are arranged under the fractionating cone 6. The air chamber 9 has a ventilation hole with a hood, and the main body 4 is also provided with a furnace door, which is located above the bottom of the retort tube 5 for ignition or inspection of the furnace.

[0023] In order to control the temperature of the retort tube 5, a water-cooled wall 7 for heat resistance and heat absorption is arranged on the periphery of the retort...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com