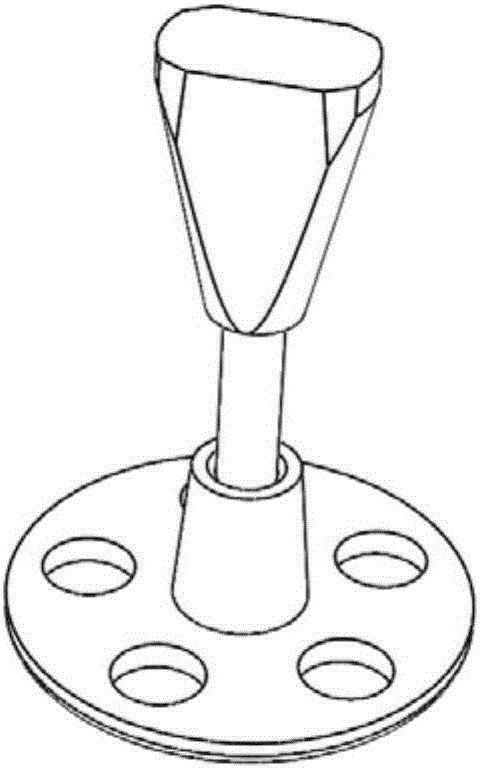

Passive middle ear implantation device and preparation method for same

An ear implant, pure titanium technology, applied in the field of biomedical engineering, can solve problems such as low efficiency and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The forming mold adopts a two-plate mold and a four-cavity structure. The temperature of the mold temperature controller is set at 50°C. The mold adopts a needle-valve hot runner and a vacuum pumping interface auxiliary facility. The gate is located at the outer edge of the disc.

[0063] (1) The D50 of pure titanium powder in the injection material is 16 μm, and the purity meets the chemical composition requirements of the first-grade pure titanium. The volume percentage of pure titanium powder is 60%, and the binder is PEG5000+PMMA95000+SA. The volume percentage of each component in the formula is: PEG5000 86.8%, PMMA95000 10.5%, SA 2.7%, the binder accounts for 40% of the volume percent of the injection material; the above pure titanium powder and binder are placed under an argon protective atmosphere In a blender, heat to 160°C, and after mixing evenly, use granulation equipment to make injection granules with a diameter of about 3mm.

[0064] (2) Put the above-ment...

Embodiment 2

[0071] The forming mold adopts a two-plate mold and a four-cavity structure. The temperature of the mold temperature controller is set at 52°C. The mold adopts a needle-valve hot runner and a vacuum pumping interface auxiliary facility. The gate is located at the outer edge of the disc.

[0072] (1) Pure titanium powder D in the injection material 50 The purity is 5 μm, and the purity meets the chemical composition requirements of first-grade pure titanium. The volume percentage of pure titanium powder is 60%, the binder is PEG7000+PMMA75000+SA, and the volume percentage between the components of the binder is PEG7000 84.8%, PMMA75000 12.5% %, SA 2.7%, the volume percentage of binder is 40%. Put the above pure titanium powder and binder in a mixer under an argon protective atmosphere, heat to 175°C, and after mixing evenly, use granulation equipment to make injection granules with a diameter of about 3mm.

[0073] (2) Put the above-mentioned injection material into the hopper...

Embodiment 3

[0080] The forming mold adopts a two-plate mold and a four-cavity structure. The temperature of the mold temperature controller is set at 40°C. The mold adopts a needle valve type hot runner and a vacuum pumping interface auxiliary facility. The gate is located at the outer edge of the disc.

[0081] (1) Pure titanium powder D in the injection material 50The purity is 25 μm, and the purity meets the chemical composition requirements of the first-grade pure titanium. The volume percentage of pure titanium powder is 64%, the binder is PEG5000+PMMA95000+SA, and the volume percentage between the components of the binder is PEG5000 86.8%, PMMA95000 10.5 %SA 2.7%, the volume percentage of binder is 36%. Put the above pure titanium powder and binder in a mixer under an argon protective atmosphere, heat to 150°C, and after mixing evenly, use granulation equipment to make injection granules with a diameter of about 3mm.

[0082] (2) Put the above-mentioned injection material into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com