Dust removal nozzle and dust removal device

A nozzle and gas ejection technology, applied in the direction of spraying devices, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of reduced cleaning efficiency, consumption, and disconnection of small faces, so as to reduce air consumption and improve cleaning efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, the present invention will be described in detail based on drawings showing embodiments.

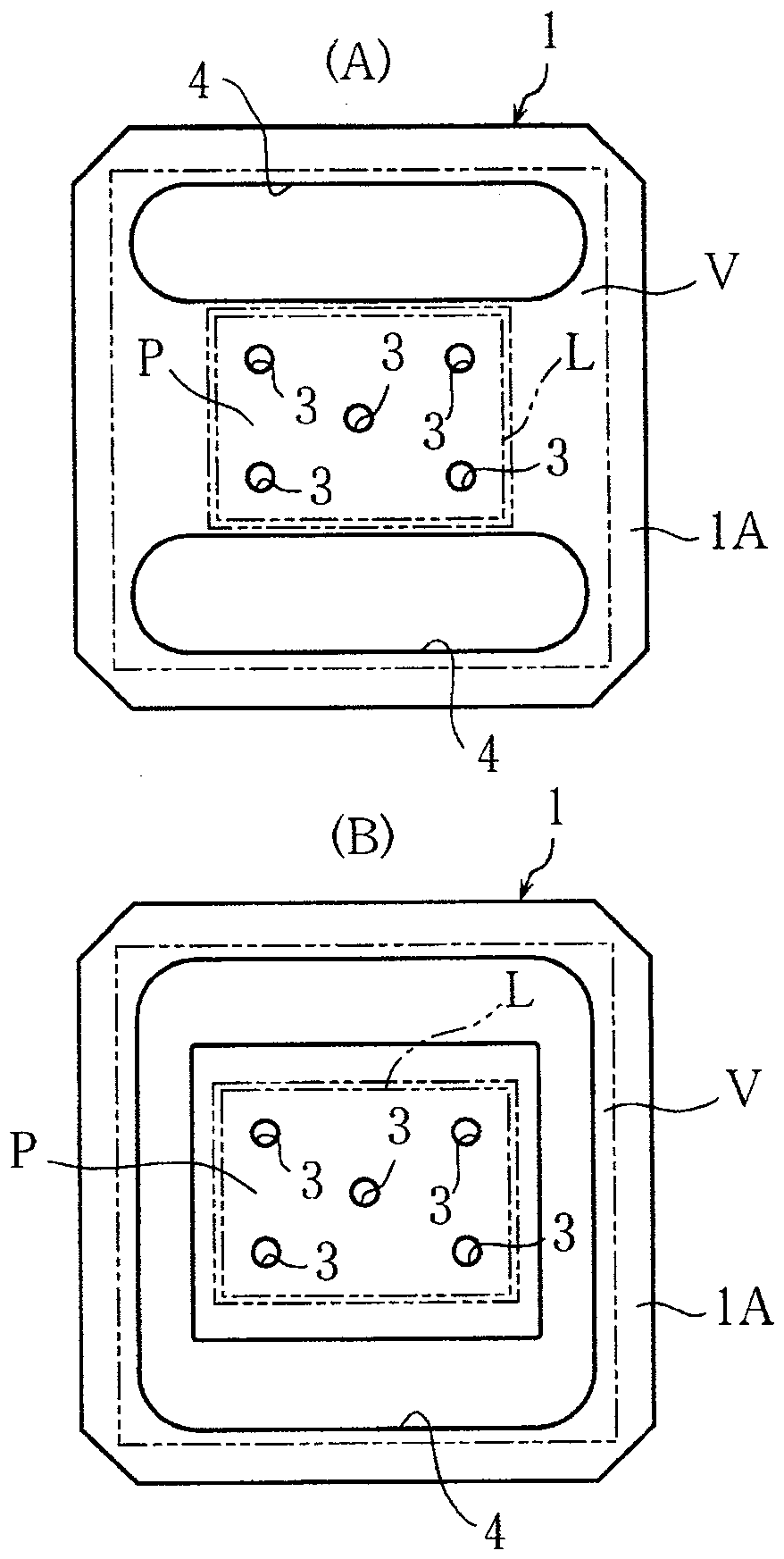

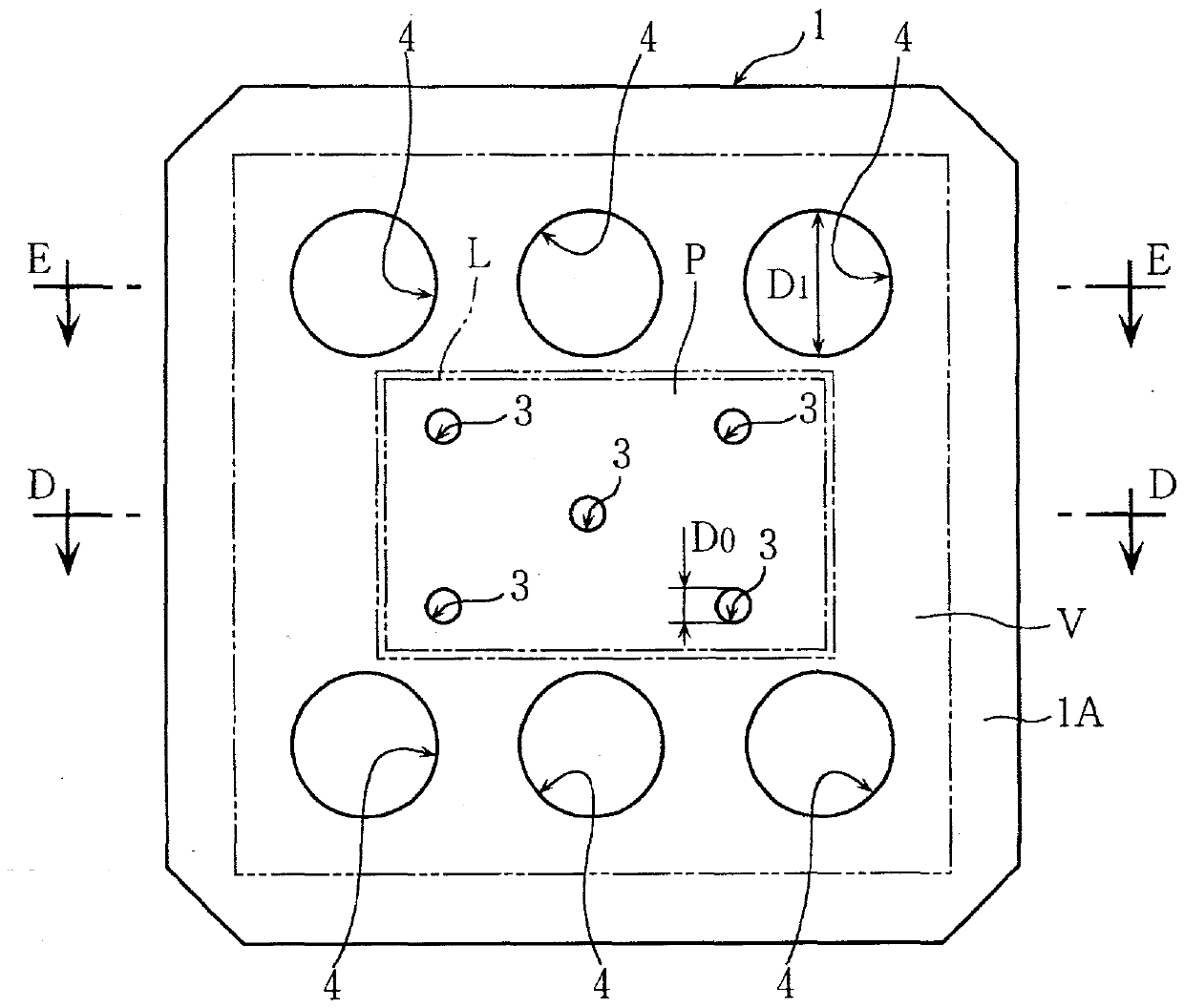

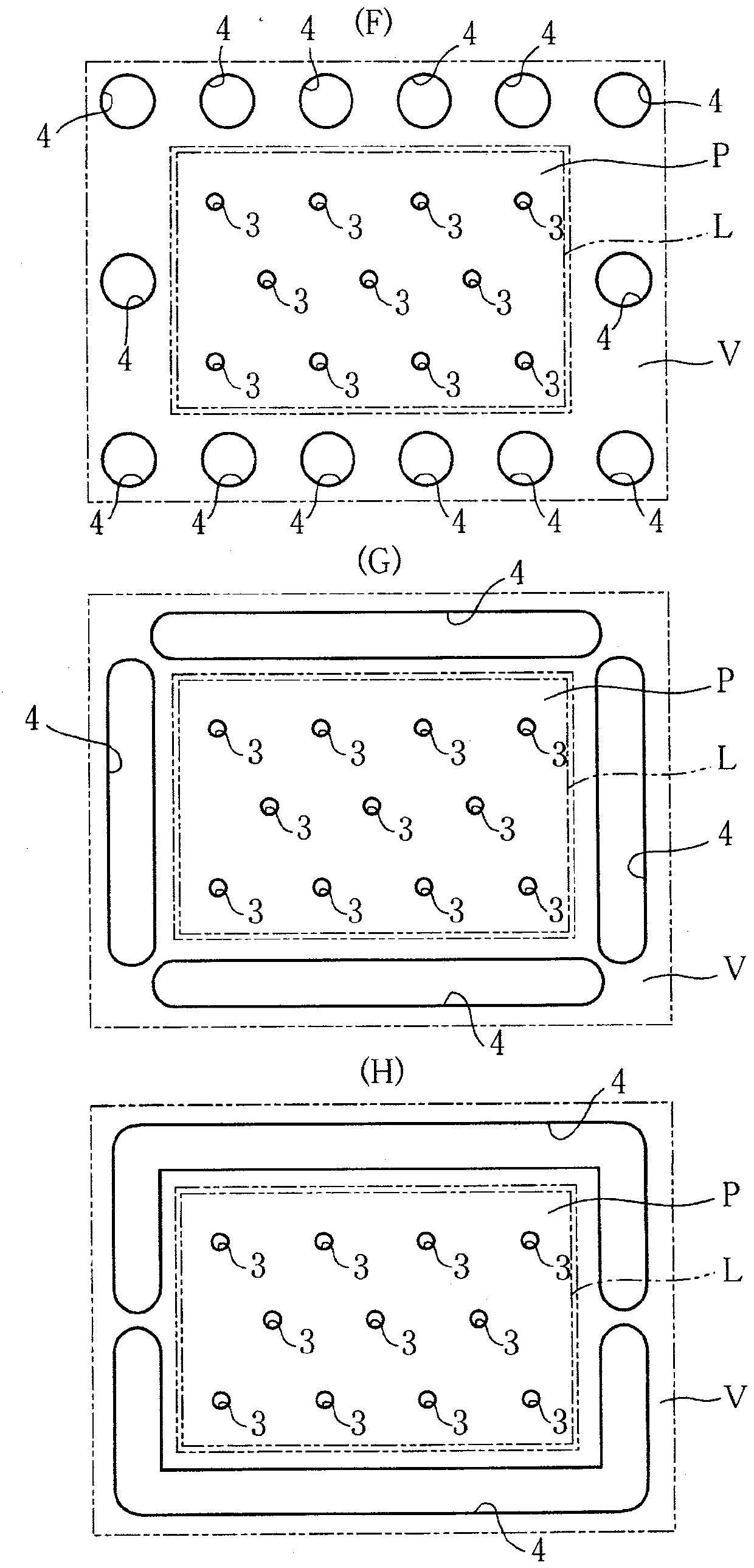

[0023] Figure 4 One embodiment of a dust removal device having a dust removal nozzle according to the present invention is shown, and the device is used for dust removal and cleaning by blowing gas to an electronic component 6 partially equipped with a small surface area 2 to be dust removed. For example, the electronic components 6 are arranged in a grid or zigzag on a printed circuit board or a cassette tray, and dust removal nozzles 1 are arranged corresponding to each column of the electronic components 6, and one dust removal nozzle 1 is arranged relative to each One place on the electronic component 6 wants dust removal small face 2 to be opposite shape.

[0024] Such as image 3 As shown, the dust-removing small face 2 is made of sensors such as a CMOS image sensor or a CCD image sensor, for example. On the electronic component 6, the micro-fine wiring 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com