Synthetic method of biological structural carbon/cerium oxide artificial photosynthesis material

A biological structure and photosynthetic material technology, applied in hydrogen/synthesis gas production, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of titanium dioxide without visible light response ability, low repeated utilization rate, and limited service life, etc. Achieve the effect of wide application value, improve utilization rate and enhance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The synthetic method of biological structure carbon / cerium oxide artificial photosynthetic material comprises the following steps:

[0019] The first step: pretreatment of leaves: Bamboo bamboo leaves are soaked in a mixture of 5% dilute hydrochloric acid and 95% absolute ethanol and distilled water with a volume ratio of 3:1 for 12 hours, washed with distilled water after taking them out, and then Soak for 12 hours with 5% dilute hydrochloric acid and 95% mixture of absolute ethanol and distilled water with a volume ratio of 3:1;

[0020] Step 2: Prepare 1 L of cerium nitrate aqueous solution with a concentration of 0.1 mol / L. After stirring and dissolving, soak 10 g of Bamboo bamboo leaves that have been pretreated in the solution for 24 hours, take it out, wash it, and dry it;

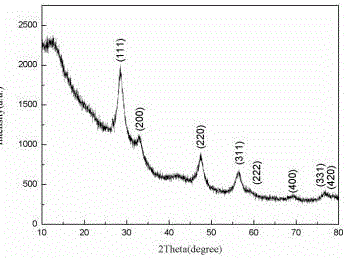

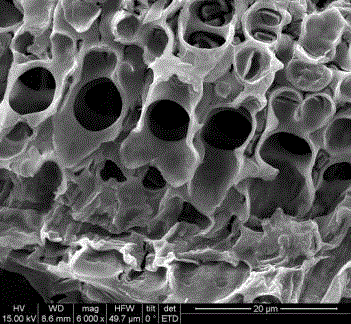

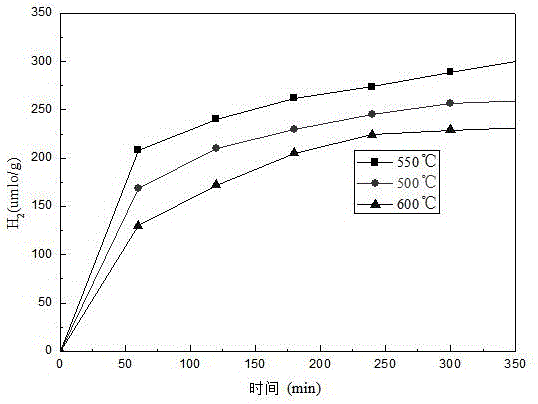

[0021] Step 3: Heat the treated blade template to 700°C under the protection of nitrogen atmosphere, calcining for 196 minutes, then change to air atmosphere, calcining at 550°C for 3 hours, ...

Embodiment 2

[0026] The synthetic method of biological structure carbon / cerium oxide artificial photosynthetic material comprises the following steps:

[0027] The first step: pretreatment of leaves: willow leaves are soaked in a mixture of 5% dilute hydrochloric acid and 95% absolute ethanol and distilled water with a volume ratio of 3:1 for 12 hours, taken out, washed with distilled water, and then used Soak in a mixture of 5% dilute hydrochloric acid and 95% absolute ethanol and distilled water at a volume ratio of 3:1 for 18 hours;

[0028] Step 2: Prepare 1L aqueous solution of cerium chloride with a concentration of 0.15mol / L. After stirring and dissolving, soak the pretreated willow leaves in the solution for 48 hours, take it out, wash it, and dry it;

[0029] Step 3: Heat the treated blade template to 600°C under the protection of nitrogen atmosphere, calcining for 400 minutes, then change to air atmosphere, calcining at 500°C for 3 hours, and cool naturally.

[0030] Through the...

Embodiment 3

[0032] The synthetic method of biological structure carbon / cerium oxide artificial photosynthetic material comprises the following steps:

[0033] The first step: pretreatment of the leaves: the leaves of the star anise gold plate are soaked in a mixture of 5% dilute hydrochloric acid and 95% absolute ethanol and distilled water with a volume ratio of 3:1 for 12 hours, and then washed with distilled water after taking them out. Soak with 5% dilute hydrochloric acid and 95% mixture of absolute ethanol and distilled water with a volume ratio of 3:1 for 24 hours;

[0034] Step 3: Prepare 1L aqueous solution of cerium sulfate with a concentration of 1mol / L. After stirring and dissolving, soak the pretreated star anise gold plate leaf in the solution for 24 hours, take it out, wash it with distilled water, and dry it;

[0035] Step 3: Heat the treated leaf template to 650°C under the protection of nitrogen atmosphere, calcining for 380 minutes, then change to air atmosphere, calcin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com