Porous carbon fiber paper electrode material for vanadium redox flow battery and its preparation and application

An all-vanadium redox flow battery and porous carbon fiber technology, which can be used in fuel cells, circuits, electrical components, etc., can solve the problems of large electrode thickness and low electrocatalytic activity of all-vanadium redox flow batteries, and achieve high practical value and improve performance. Surface area, the effect of improving voltage efficiency and energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

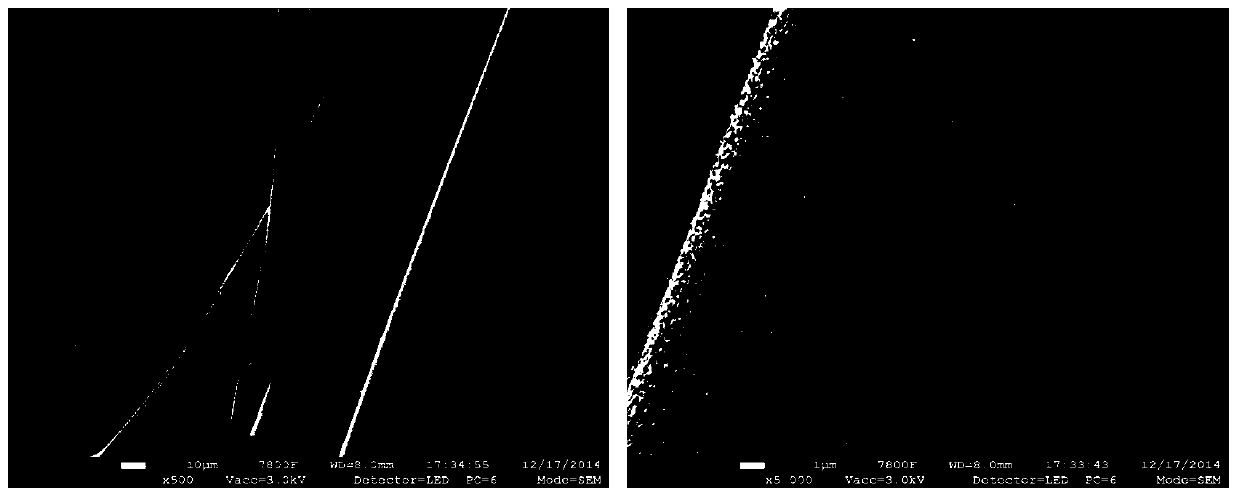

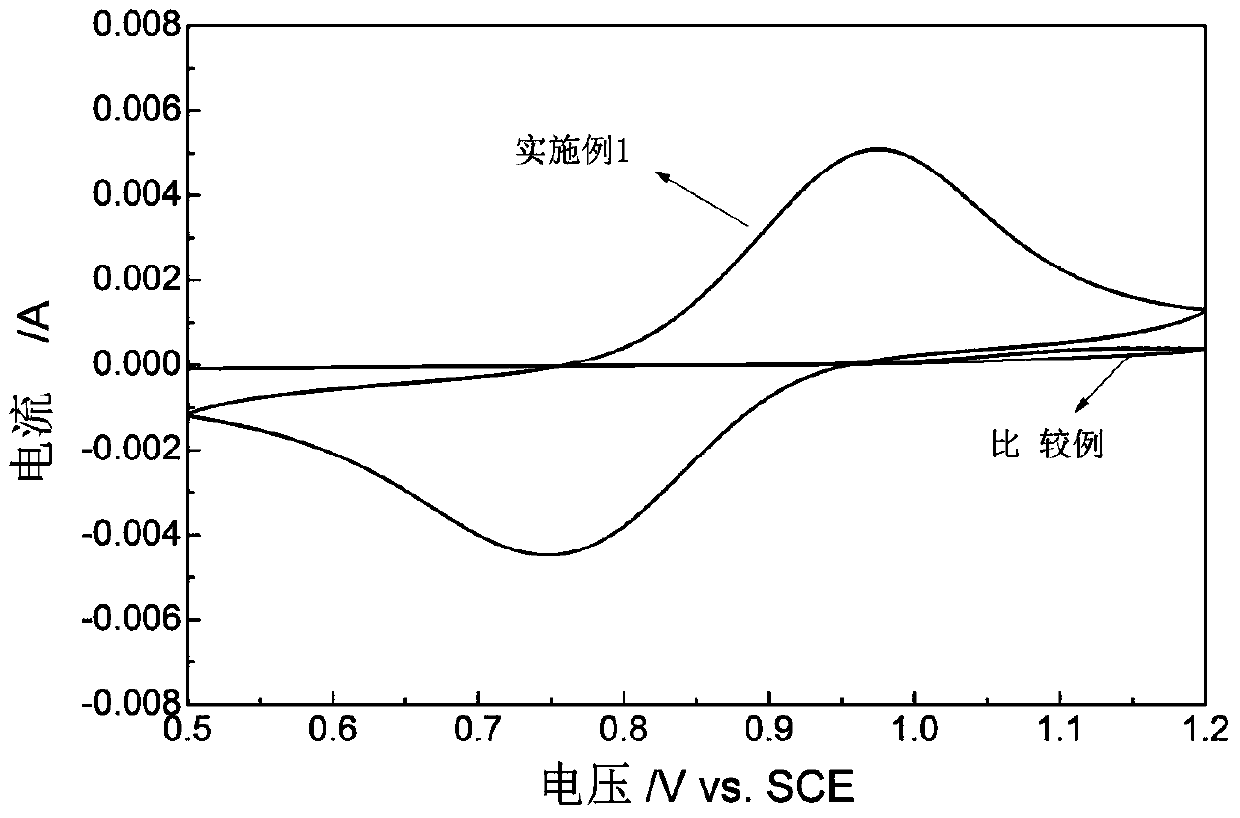

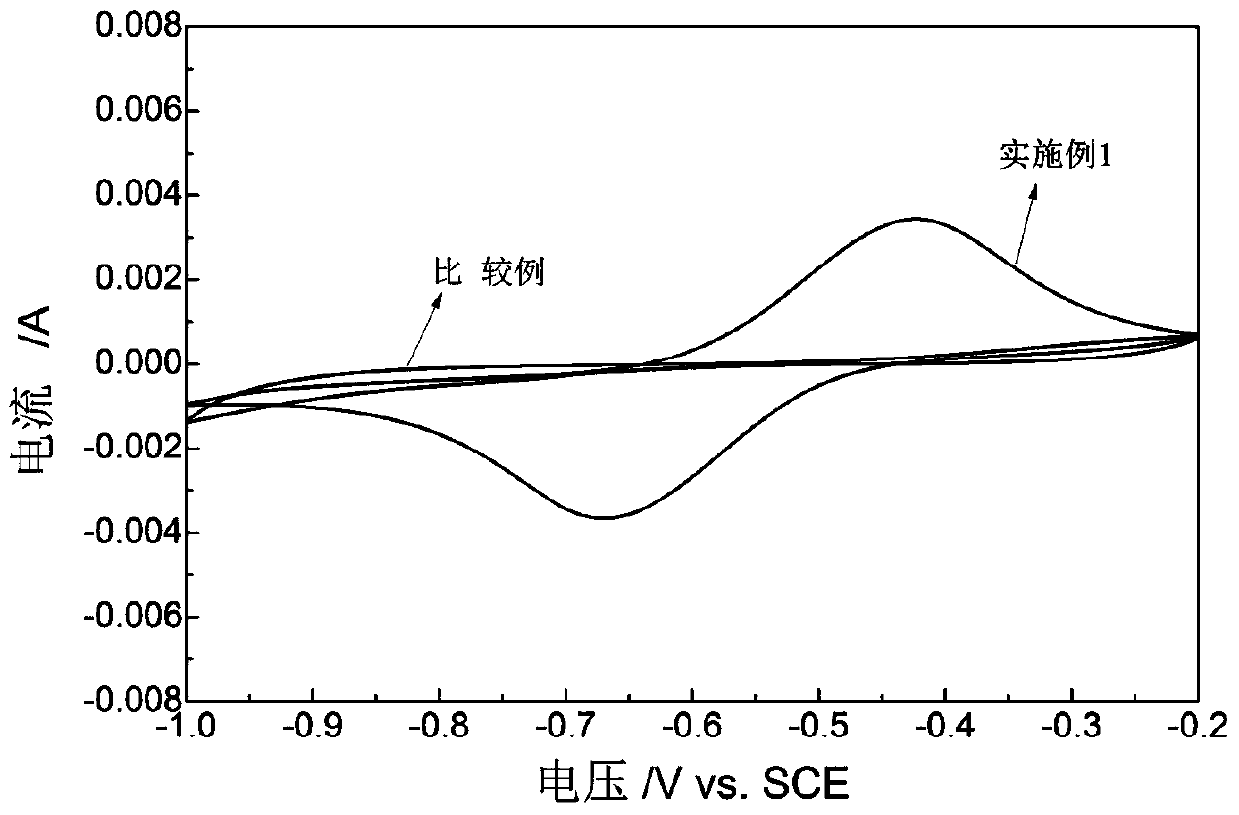

Embodiment 1

[0050] Prepare polyacrylonitrile-based chopped carbon fibers with a length of 10mm, degumming them in an acetone solution, and then put them into an aqueous solution containing 0.1% polyethylene oxide dispersant for beating to form polyacrylonitrile-based carbon fiber slurry, Then it is copied by wet forming equipment to make the weight per unit area 40g / m 2 carbon paper precursor; after that, immerse it in an ethanol solution with a phenolic resin concentration of 1% for 30min, and then heat-press at 200°C to obtain a carbon paper base paper at a pressure of 6 MPa after drying; The paper base paper is put into the electric furnace, under N 2 Under the atmosphere, the temperature was raised to 1600°C at a heating rate of 10°C / min, and the temperature was kept constant for 1 hour; then the temperature was lowered to 1300°C, and CO 2 and N 2 gas mixture, CO 2 and N 2 The flow rates were 40ml / min and 200ml / min, respectively, and the constant temperature was reacted for 30min;...

Embodiment 2

[0059] Prepare a pitch-based chopped carbon fiber with a length of 15mm, degumming it in an acetone solution, and then put it into an aqueous solution containing 0.05% polyacrylamide dispersant for beating to form a pitch-based carbon fiber slurry, and then wet Forming equipment is copied to form a unit area weight of 50g / m 2 carbon paper precursor; after that, immerse it in an ethanol solution with a phenolic resin concentration of 1% for 30 minutes, and then heat-press at 180°C to obtain a carbon paper base paper at a pressure of 5 MPa after drying; The paper base paper is put into the electric furnace, under N 2 Under the atmosphere, the temperature was raised to 1400°C at a heating rate of 5°C / min, and the temperature was kept constant for 1 hour; then the temperature was lowered to 800°C, and water vapor and N 2 mixture of gas, water vapor and N 2 The flow rates were 10ml / min and 200ml / min respectively, and the reaction was carried out at constant temperature for 30min;...

Embodiment 3

[0062] Prepare viscose-based chopped carbon fibers with a length of 10 mm, degumming them in an acetone solution, and putting them into an aqueous solution containing 0.05% polyacrylamide dispersant for beating to form viscose-based carbon fiber slurry, and then The weight per unit area of wet forming equipment is 50g / m 2 carbon paper precursor; after that, immerse it in an ethanol solution with a phenolic resin concentration of 0.5%, soak for 30min, and then heat-press at 180°C to obtain a carbon paper base paper at a pressure of 5MPa after drying; The paper base paper is put into the electric furnace, under N 2 Under the atmosphere, the temperature was raised to 1300°C at a heating rate of 5°C / min, and the temperature was kept constant for 1h; then the temperature was kept constant, and CO 2 and N 2 gas mixture, CO 2 and N 2 The flow rates were 20ml / min and 200ml / min respectively, and the reaction was carried out at constant temperature for 30min; then cooled to room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com