Carbon nanotube and ceramic nanoparticle hybrid reinforced magnesium-based composite material and preparation method thereof

A technology of composite materials and carbon nanotubes, applied in the field of magnesium-based composite materials, to achieve good mechanical properties and high temperature resistance, broad market prospects, and good damage effects such as material fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

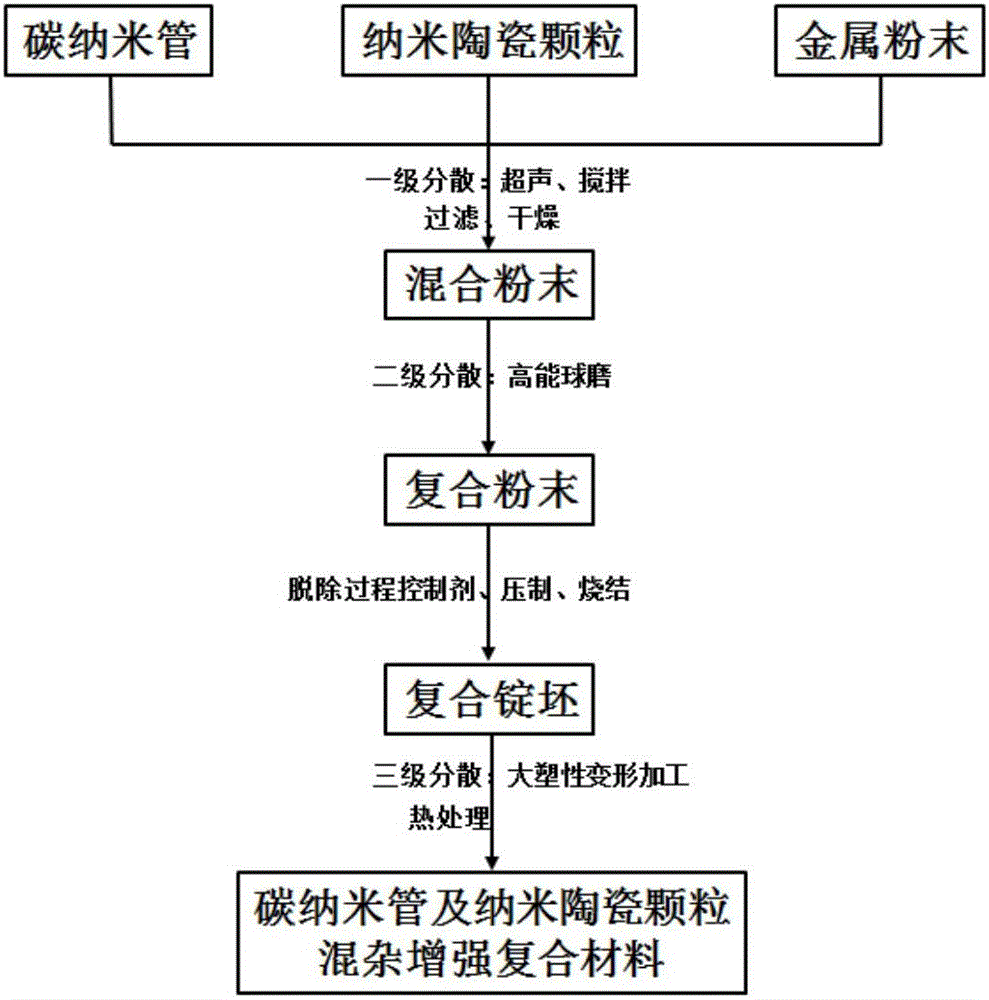

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, the preparation of magnesium-based composite material of the present invention

[0037] (1) Get 6g multi-walled carbon nanotubes (diameter 50nm, length 10 μ m), 4g nano-silicon carbide particles (average particle diameter is 40nm), 181g magnesium powder, 6g aluminum powder, 2g zinc powder, 0.2g mixed rare earth (wherein, Mixed rare earths are mainly composed of lanthanum, cerium, praseodymium, and neodymium, and their weight percentages are 10%, 55%, 10%, and 25% respectively) powder and 0.2g silver powder (in the above alloyed powder, the average particle size of magnesium powder is 70μm , the average particle size of aluminum powder, zinc powder and mixed rare earth is 50 μm), added to ethanol, ultrasonically dispersed for 30 minutes, and then mechanically stirred at a speed of 300 rpm for 30 minutes, so that the nano-reinforcement body is uniformly dispersed on the surface of the metal powder, filtered, Vacuum drying to obtain mixed powder;

[0038] (2...

Embodiment 2

[0041] Embodiment 2, the preparation of magnesium-based composite material of the present invention

[0042] (1) Take 5g multi-walled carbon nanotubes (diameter 50nm, length 10μm), 5g nano-silicon carbide particles (average particle diameter is 40nm), 172g magnesium powder, 11.5g aluminum powder, 5.5g zinc powder, 0.2g mixed rare earth powder And 0.2g silver powder (in the above-mentioned alloying powder, the average particle diameter of magnesium powder is 70 μ m, and the average particle diameter of aluminum powder, zinc powder and mixed rare earth is 50 μ m), joins in the ethanol, ultrasonic dispersion 20min, then at a rotating speed of Stir mechanically at 400rpm for 40 minutes to disperse the nano-reinforcement evenly on the surface of the metal powder, filter, and dry in vacuum to obtain a mixed powder;

[0043](2) Take the above mixed powder, and add 0.6g of stearic acid as a process control agent, under the protection of an inert gas (argon), perform high-energy ball m...

Embodiment 3

[0046] Embodiment 3, the preparation of magnesium-based composite material of the present invention

[0047] (1) Take 5g multi-walled carbon nanotubes (diameter 50nm, length 10μm), 5g nano-silicon carbide particles (average particle diameter is 40nm), 173g magnesium powder, 15g aluminum powder, 1g zinc powder, 0.2g mixed rare earth powder and 0.2 g silver powder (among the above alloyed powders, the average particle size of the magnesium powder is 70 μm, and the average particle size of the aluminum powder, zinc powder and mixed rare earths is 50 μm), is added to ethanol, ultrasonically dispersed for 25 minutes, and then heated at a speed of 300 rpm Stir mechanically for 30 minutes to disperse the nano-reinforcement evenly on the surface of the metal powder, filter, and dry in vacuum to obtain a mixed powder;

[0048] (2) Take the above mixed powder, and add 0.6g stearic acid as a process control agent, under the protection of an inert gas (argon), perform high-energy ball mil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com