Heat conducting glue for water cooling radiator and preparation method thereof

A technology of water-cooled radiators and heat-conducting adhesives, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problem of high thermal conductivity of heat-conducting adhesives, poor adhesion coefficient of long lengths, copper tubes and aluminum plates falling off, etc. problem, to achieve the effect of high shear strength, fast curing speed and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Pour the hydroxypropyl methacrylate 15, 2-hydroxyethyl methacrylate 15, and tetrahydrofuryl methacrylate 60 into the reaction kettle, mix and stir evenly;

[0020] (2) Pour alumina 340, silicon carbide 85, silicon dioxide 340, and carbon powder 85 into the reaction kettle to mix and stir evenly;

[0021] (3) Grinding the mixture obtained in step (2) to a uniform flowing continuous paste;

[0022] (4) Add benzoyl peroxide 50 to the paste obtained in step (3) and stir evenly;

[0023] (5) The thermally conductive adhesive is obtained after vacuum defoaming, and filled and sealed.

Embodiment 2

[0025] (1) Pour the hydroxypropyl methacrylate 80, 2-hydroxyethyl methacrylate 80, and tetrahydrofuryl methacrylate 300 into the reaction kettle to mix and stir evenly;

[0026] (2) Pour alumina 200, silicon carbide 50, silicon dioxide 200, and carbon powder 20 into the reaction kettle to mix and stir evenly;

[0027] (3) Grinding the mixture obtained in step (2) to a uniform flowing continuous paste;

[0028] (4) Add benzoyl peroxide 10 to the paste obtained in step (3) and stir evenly;

[0029] (5) The thermally conductive adhesive is obtained after vacuum defoaming, and filled and sealed.

Embodiment 3

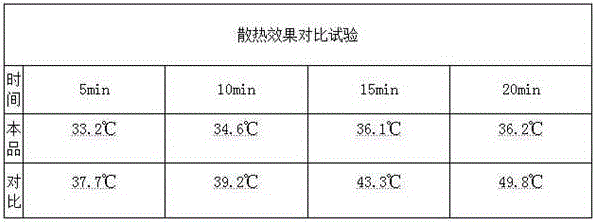

[0031] The heat sink made by filling the heat conduction adhesive of the present invention with the heat sink made of common heat conduction adhesive is carried out the temperature contrast test,

[0032] The data results are shown in Table 1:

[0033]

[0034] Table 1

[0035] It can be seen from Table 1 that the longer the working time of the electronic components, the more and more heat is emitted by the electronic components. The thermally conductive glue of the present invention can quickly conduct the heat away, and the heat is taken away by the cooling water, while the conventional heat conduction glue in comparison The heat conduction efficiency of the glue is poor, resulting in continuous accumulation of heat, and the temperature of the electronic components continues to rise.

[0036] The heat-conducting adhesive of the present invention belongs to the single-component heat-conducting adhesive, which is more convenient to use than the two-component adhesive, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com