Quick starting method for treating ammonia-containing wastewater through A/O process

A waste water and process technology, which is applied in the field of rapid start-up of A/O process to treat ammonia-containing waste water, can solve the problems of large dosage of bacteria agent and increased system start-up cost, so as to promote growth and value-added, ensure long-term stable operation, The effect of promoting rapid adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

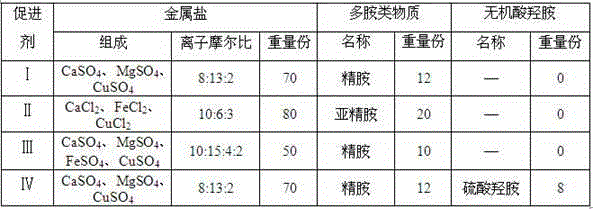

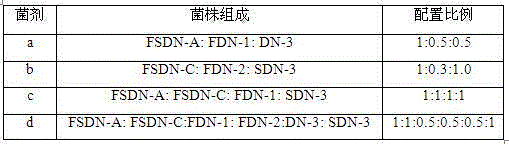

[0033] First, aerobic activated sludge was added to the O reactor according to 10% of the effective volume of the reactor, and at the same time, the growth promoter I was added to the O reactor according to the accelerator concentration in the culture system of 25mg / L, and the pH was controlled at 7.9, The temperature is controlled at 20°C, and the dissolved oxygen concentration is about 1.5-3.0mg / L. The next day, anaerobic activated sludge was added to reactor A according to 10% of the effective volume of the reactor, and denitrification bacteria agent a was added to reactor A according to 0.1% of the volume ratio, the pH value was controlled at 8.0, and the dissolved oxygen concentration was 0.5~1.0mg / L. The ammonia-containing wastewater with a concentration of 250mg / L is used as the feed water of the O reactor, and the supernatant of the O reactor is used as the feed water of the A reactor. Water is fed intermittently first, and each batch is reacted for 24 hours. After th...

Embodiment 2

[0035] First, aerobic activated sludge was inoculated into the O reactor according to 20% of the effective volume of the reactor. At the same time, the growth promoter II was added according to the concentration of the promoter in the culture system of 25 mg / L, the pH was controlled at 8.0, the temperature was controlled at 30°C, and the dissolved oxygen concentration was about 2.5-4.0 mg / L. The next day, add anaerobic activated sludge to reactor A according to 40% of the effective volume of the reactor, and then add denitrification bacteria agent b to reactor A according to the volume ratio of 0.05%. The pH value is controlled at 8.0, and the dissolved oxygen concentration 0.1~1.0mg / L. The ammonia-containing wastewater with a concentration of 200mg / L is used as the feed water of the O reactor, and the supernatant of the O reactor is used as the feed water of the A reactor. Water is fed intermittently first, and each batch is reacted for 24 hours. After the O reactor stops ae...

Embodiment 3

[0037] First, aerobic activated sludge was inoculated into the O reactor according to 30% of the effective volume of the reactor. At the same time, the growth promoter III was added according to the concentration of the promoter in the culture system of 20 mg / L, the pH was controlled at 8.0, the temperature was controlled at 30°C, and the dissolved oxygen concentration was about 2.5-4.0 mg / L. The next day, add anaerobic activated sludge to reactor A according to 25% of the effective volume of the reactor, and then add denitrification agent c to reactor A according to the volume ratio of 0.05%, control the pH value at 8.0, and the concentration of dissolved oxygen 0.1~1.0mg / L. The ammonia-containing wastewater with a concentration of 200mg / L is used as the feed water of the O reactor, and the supernatant of the O reactor is used as the feed water of the A reactor. Water is fed intermittently first, and each batch is reacted for 24 hours. After the O reactor stops aeration, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com