Device used for removing slag from edible film

An edible film and equipment technology, which is applied in the separation of solids from solids by air flow, solids separation, chemical instruments and methods, etc. problems, to achieve the effect of improving product quality and efficiency, and reliable and continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

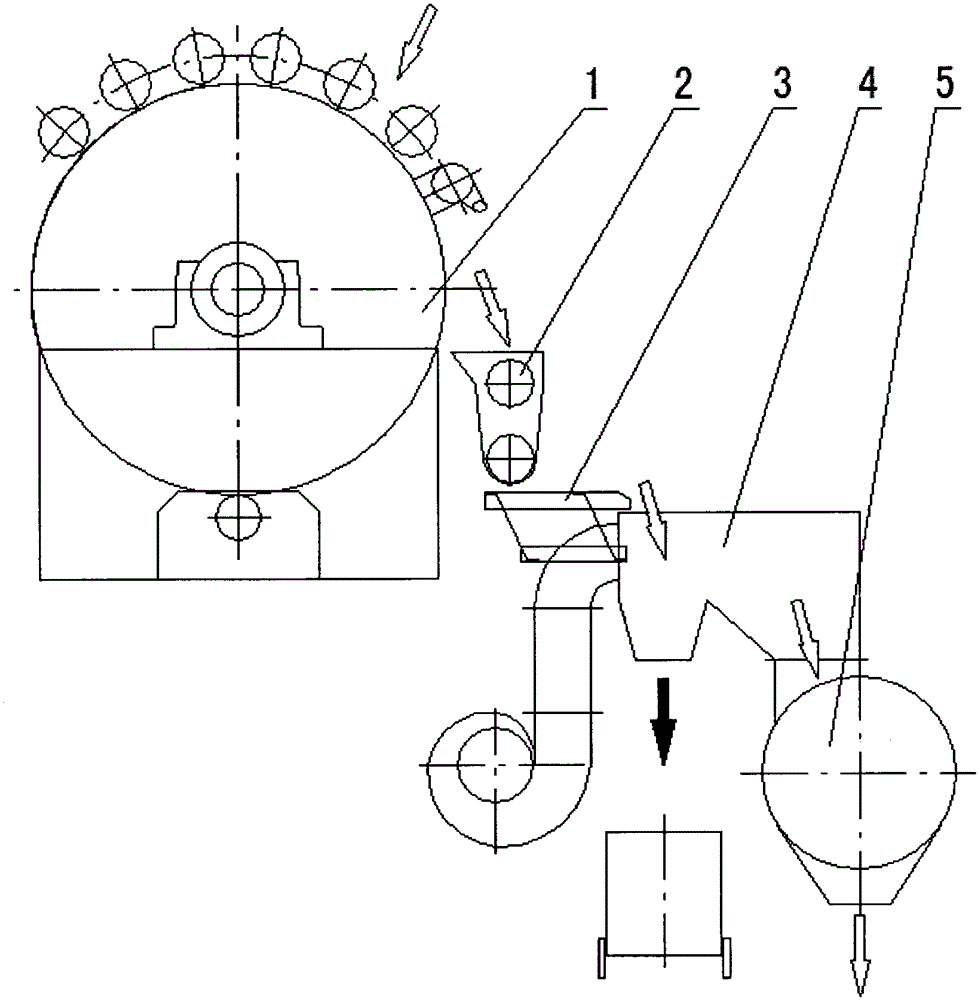

[0020] Example 1 figure 1 Shown is a schematic diagram of a device for removing slag from edible membranes according to the present invention. The continuous production process of the equipment for removing slag from edible membranes is as follows: the edible membranes that have passed through the drying process are dried. The unloading scraper arranged at the discharge port of the drum dryer (1) scrapes off the machine, and then enters the diaphragm crusher (2);

[0021] The diaphragm breaker (2) uses the fragility of the edible diaphragm and the action of mechanical force to perform primary breaking of the large roll of the edible diaphragm and break it into irregular edible diaphragm fragments. During the drying process of the drum dryer (1), some wet flakes and lumps, commonly known as slag, will inevitably be produced, and these slag will then enter the diaphragm crusher (2) Inside, mixed in the edible diaphragm fragments, the conveying screw built in the lower part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com