External circle precise grinding method of super-long-diameter tool

A precision grinding and cutting tool technology, applied in the field of cutting tool precision grinding, can solve the problems of low grinding efficiency and unstable grinding quality, and achieve the effects of reducing scrap rate, improving efficiency and product quality, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

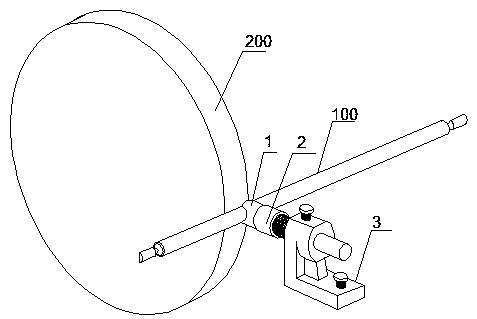

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

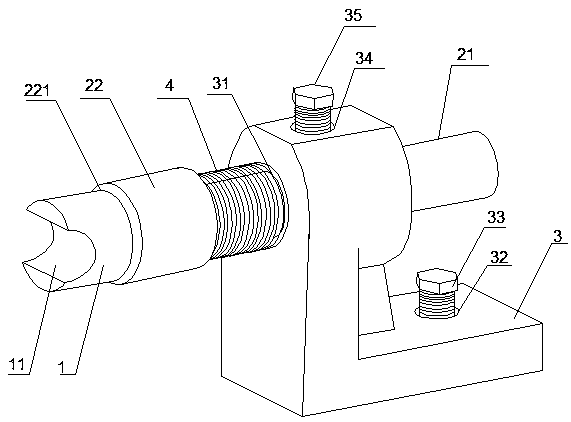

[0038] Such as figure 2As shown, the pressing device includes a U-shaped limit block 1, a guide rod 2 and a fixed slider 3 installed on the guide rail of the grinding machine; one end of the guide rod 2 is installed on one side of the fixed slider 3, and the The end of the guide rod 2 away from the fixed slider 3 is connected to a limit block; the end of the U-shaped limit block 1 away from the guide rod 2 is provided with a U-shaped groove 11 . The fixed slider 3 is an L-shaped slider that includes a panel and a web that are connected as one, and the panel is provided with a fastening screw hole 34, and the fixed slider 3 passes through the tightening screw hole 34. The fastening screw 33 is detachably connected with the guide rail of the grinder; the guide rod 2 is installed on one side of the web. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com