Building formwork net making method and equipment

An assembly method and mold net technology, applied in construction, building components, building structures, etc., can solve problems such as low production efficiency, inability to match parts and components, and unsuitable quality assurance, and achieve the effect of improving efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

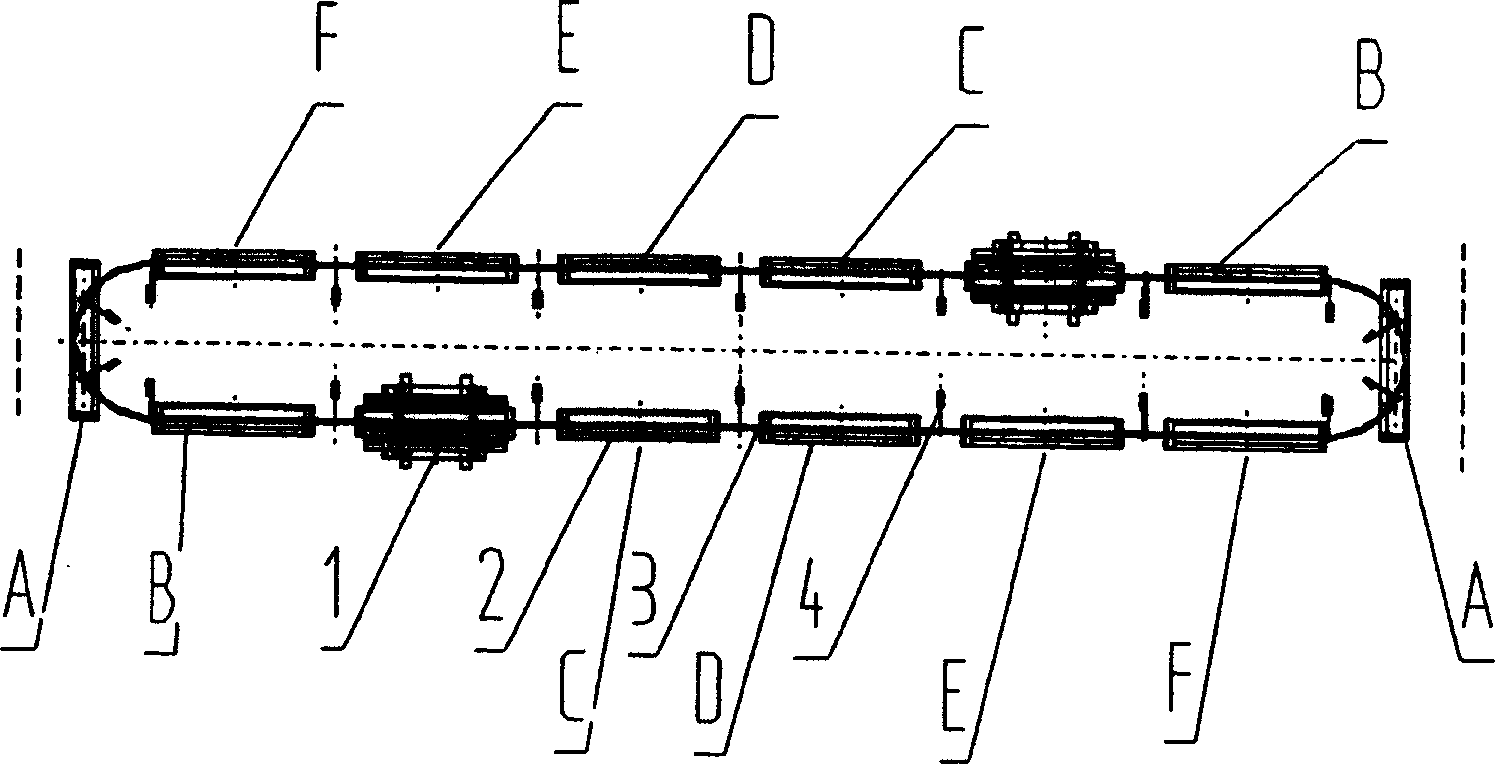

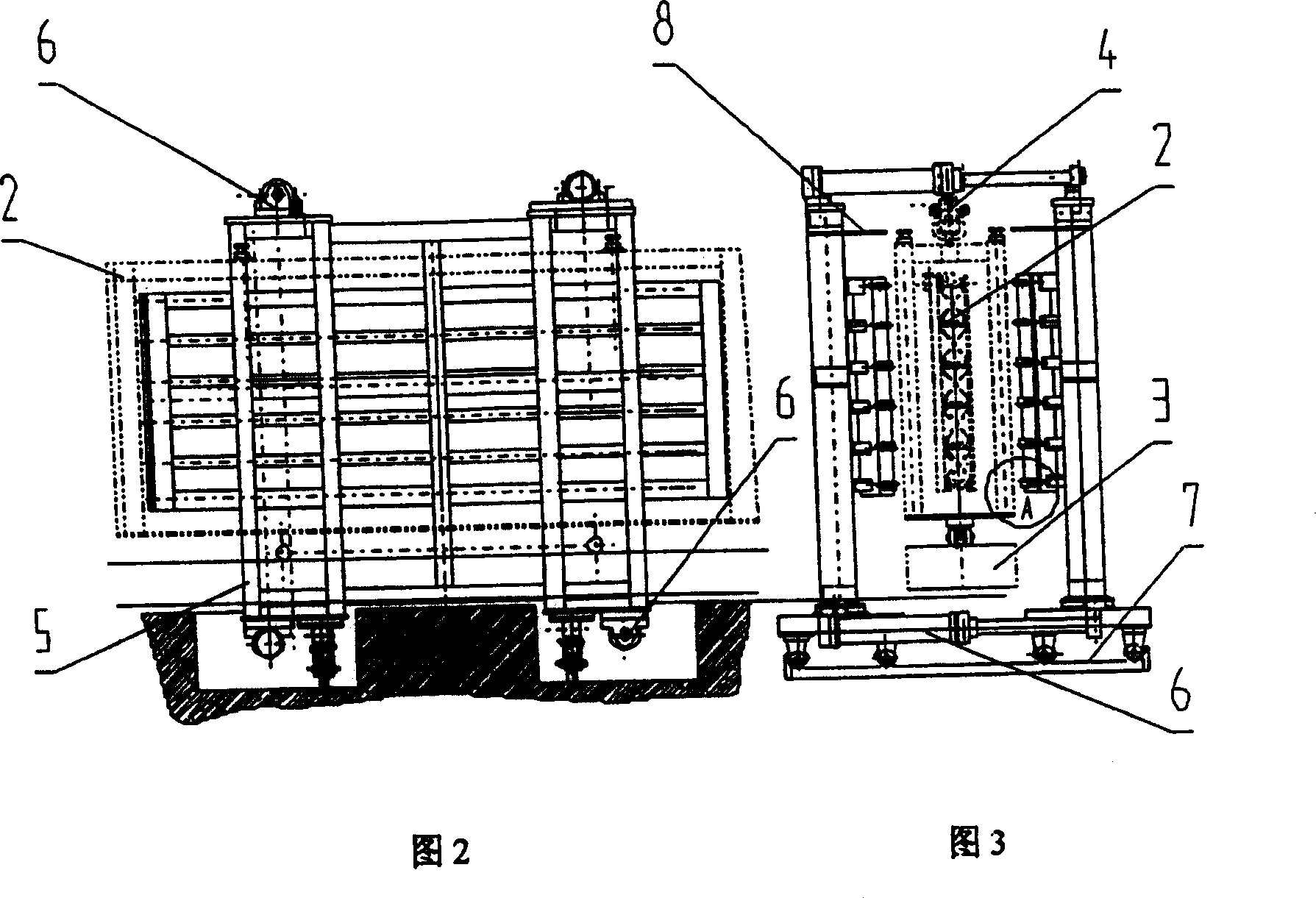

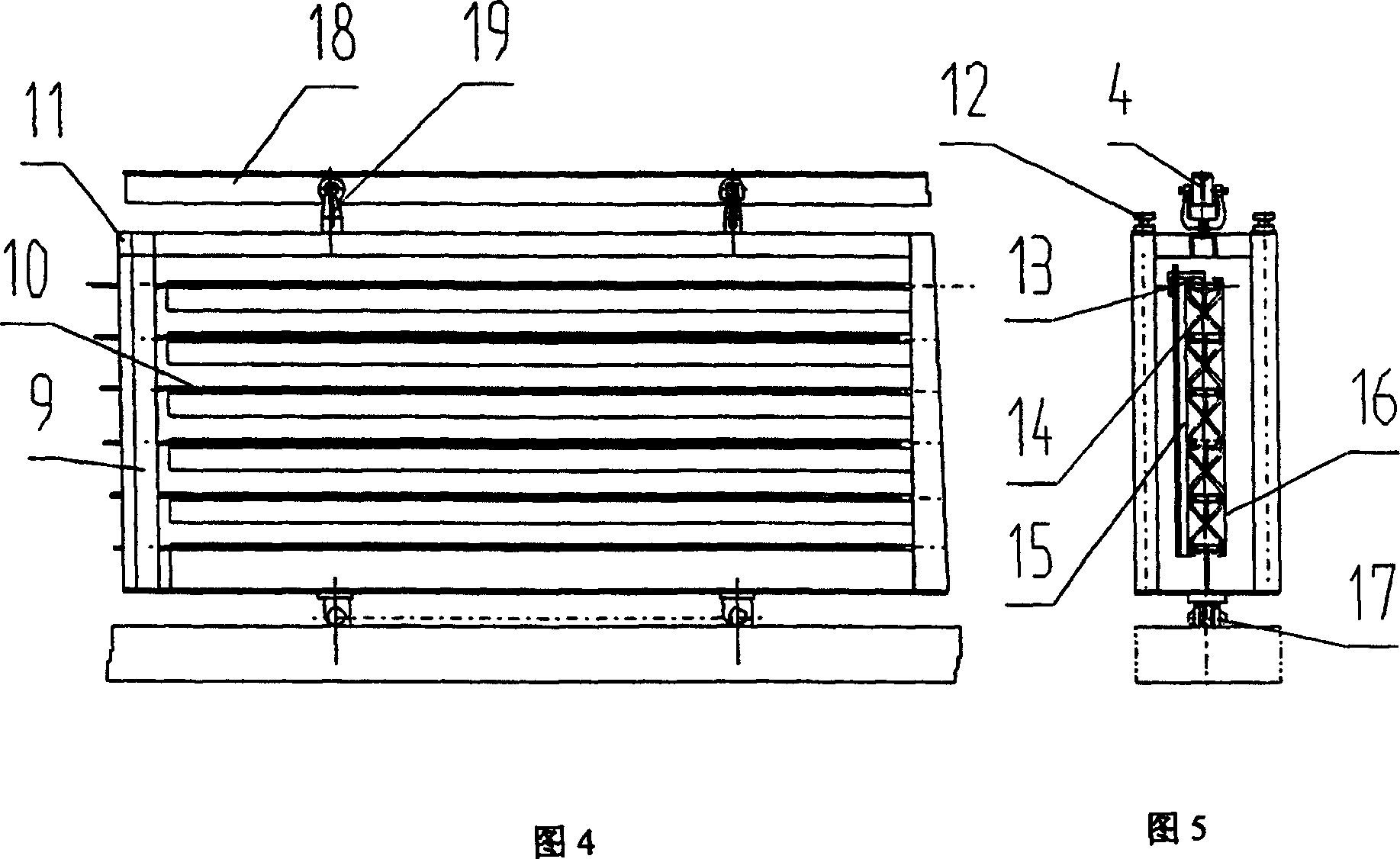

[0027] Such as figure 1 As shown, an assembly method of a building formwork net is a semi-automatic circular assembly line, on which more than one accompanying fixed grid frame 2 is arranged to run along the circular line, and A, B, C, D, E, F workers are arranged. Station A is symmetrical at the left and right circular lines, stations B, C, D, E, and F are symmetrical at the front and rear straight lines, and station B is equipped with press station 1 at the rear of station B. 1 Complete the main pressing work, and complete the assembly of other parts at other stations. The specific assembly process steps are: when assembling the mold net with insulation layer, first put the keel and folding hook and tie bars into the accompanying On the press-fit template in the fixed grid frame, arrange the keel and the hook and tie bars at the B station, and hang the expanded steel mesh on the connecting hook of the keel on the inside, press-fit at the press-fitting machine, and press-fit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com