Synthesis method and application of nanometer silver/silicon dioxide Raman surface enhanced thin film

A silica, surface-enhanced technology, used in Raman scattering, filament/wire forming, single-component synthetic polymer rayon, etc. problem, to achieve the effect of good experimental repeatability, wide application and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

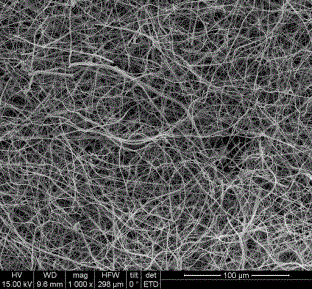

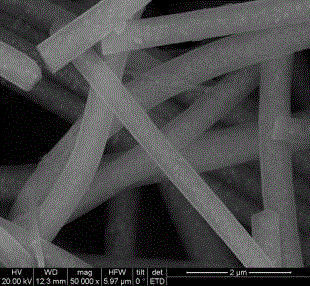

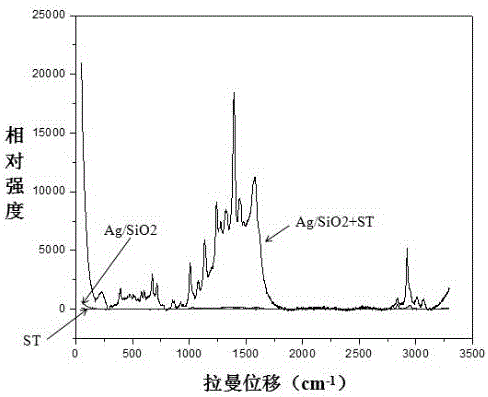

Image

Examples

Embodiment 1

[0018] The synthesis method of nano silver / silicon dioxide Raman surface enhanced film is:

[0019] Step 1: Preparation of spinning solution: Weigh 2g of PVP with a molecular weight of 1.3 million and dissolve it in 30mL of ethanol, stir magnetically for 2 hours, slowly add 2.23mL tetraethyl orthosilicate dropwise, stir for 4 hours to obtain solution A, and then Dissolve 0.085g of silver nitrate in 5mL of water, then slowly add it dropwise to solution A, and stir for 24 hours;

[0020] The second step: at a temperature of 20°C and a humidity of 55%, the positive voltage of the electrospinning is controlled to be 16KV, the negative voltage is -3KV, the spinning distance is 20cm, and the spinning speed is 0.4mm / min. Liquid spinning is made into thin film material, irradiated by fluorescent lamp, and left to stand for 6 hours;

[0021] Step 3: Remove the film, put it in a vacuum drying oven, dry at 30°C for 24 hours, then calcinate at 550°C for 3 hours, and cool naturally.

[0...

Embodiment 2

[0024] The synthesis method of nano silver / silicon dioxide Raman surface enhanced film is:

[0025] Step 1: Preparation of spinning solution: Weigh 2g of PVP with a molecular weight of 2 million and dissolve it in 50mL of ethanol, stir magnetically for 2 hours, slowly add 6mL tetraethyl orthosilicate dropwise, stir for 4 hours to obtain solution A, then take Dissolve 0.6g of silver nitrate in 6mL of water, then slowly add it dropwise to solution A, and stir for 24 hours;

[0026] The second step: at a temperature of 22°C and a humidity of 60%, control the positive voltage of electrospinning to 16KV, the negative voltage to -3KV, the spinning distance to 20cm, and the spinning speed to 0.6mm / min. Liquid spinning is made into thin film material, irradiated by fluorescent lamp, and left to stand for 6 hours;

[0027] Step 3: Remove the film, put it in a vacuum drying oven, dry it at 30°C for 24 hours, then calcinate it at 500°C for 3 hours, and cool it naturally.

[0028] The d...

Embodiment 3

[0030] The synthesis method of nano silver / silicon dioxide Raman surface enhanced film is:

[0031] Step 1: Preparation of spinning solution: Weigh 2g of PVP with a molecular weight of 500,000 and dissolve it in 20mL of ethanol, stir magnetically for 2 hours, slowly add 2mL tetraethyl orthosilicate dropwise, stir for 4 hours to obtain solution A, then take Dissolve 0.3g of silver nitrate in 5mL of water, then slowly add it dropwise to solution A, and stir for 24 hours;

[0032] The second step: at a temperature of 18°C and a humidity of 50%, control the positive voltage of electrospinning to 8KV, the negative voltage to -3KV, the spinning distance to 20cm, and the spinning speed to 0.6mm / min. Liquid spinning is made into thin film material, irradiated by fluorescent lamp, and left to stand for 6 hours;

[0033] Step 3: Remove the film, put it in a vacuum drying oven, dry it at 30°C for 24 hours, then calcinate it at 700°C for 3 hours, and cool it down naturally.

[0034] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com