1000Mpa grade high-tenacity high-property-uniformity super-thick steel plate easy to weld and manufacturing method thereof

An extra-thick steel plate and uniformity technology, which is applied in the field of 1000MPa extra-thick steel plate and its manufacturing, can solve the problems of unusable, complicated production process, and increased manufacturing cost, so as to simplify the production process, reduce manufacturing cost, and achieve uniform high performance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be described in more detail below in conjunction with preferred embodiments of the present invention. However, it should be understood that the examples are only descriptions of the preferred implementation modes of the present invention, and cannot limit the protection scope of the present invention in any way.

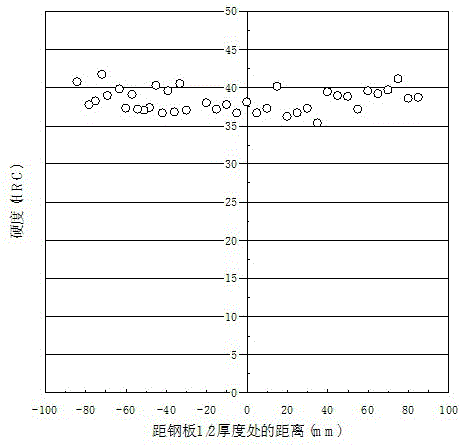

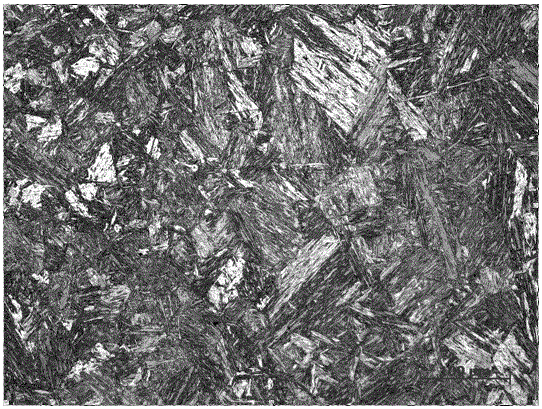

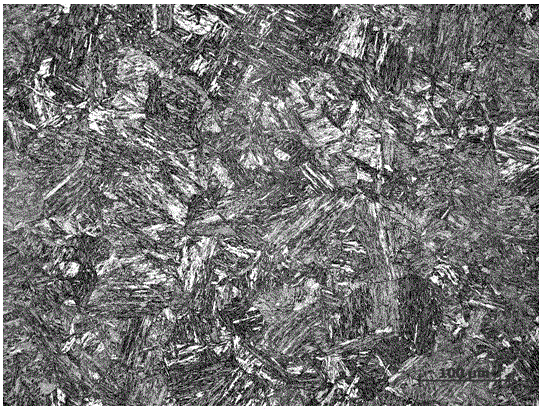

[0036] The thickness of the high-toughness, high-performance, uniform and easy-to-weld extra-thick steel plate involved in this example is 180 mm, and the components and mass percentages are: C: 0.13%, Si: 0.27%, Mn: 1.09%, P: 0.003%, S: 0.0013%, Cr: 0.70%, Mo: 0.50%, Ni: 2.52%, Cu: 0.24%, Al: 0.078%, V: 0.038%, Nb: 0.022%, N: 0.0035%, B: 0.0017%, the balance is iron and unavoidable impurity elements, carbon equivalent CEV ( = C + Mn / 6 + (Cr + Mo + V) / 5 + (Cu + Ni) / 15 ) = 0.74%, after RH treatment H in molten steel = 0.0009%.

[0037] The production process of the high-toughness, high-performance, uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com