Process method for refining aluminum alloy solidified structure by in situ generation of TiC particles

A technology of solidification structure and process method, which is applied in the preparation of high-performance aluminum alloy castings and refines the solidification structure of aluminum alloys. It can solve the problems of high temperature use restrictions, negative electrode potential, and low melting temperature, and achieve easy and simple operation. , The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

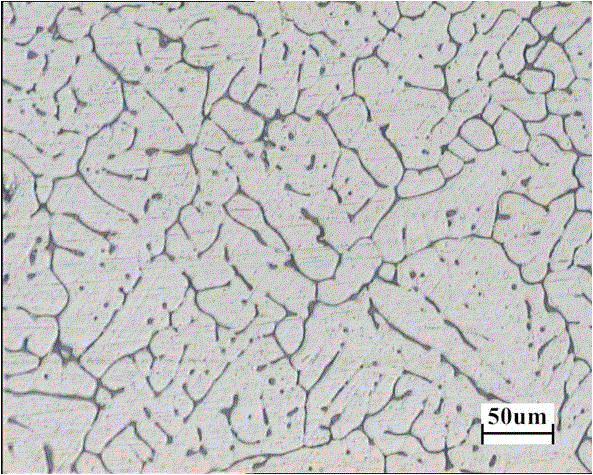

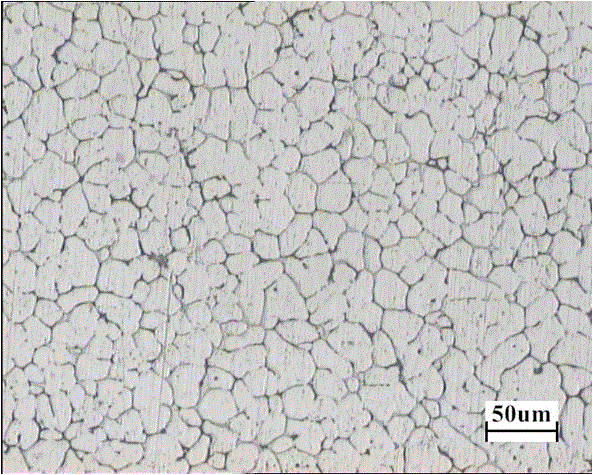

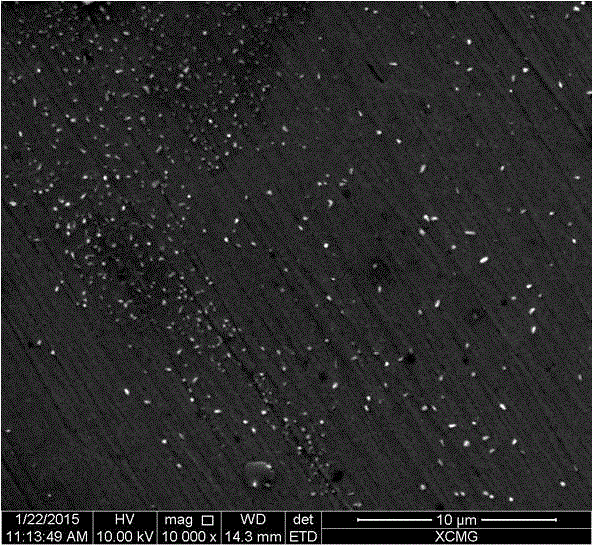

Image

Examples

Embodiment 1

[0038] Embodiment 1: 7075 alloy, tetrafluoroethane (CH 2 f 4 ) and CO 2 Mixed gas protection, melting temperature 1100°C-1150°C, heat preservation 10min, add carbon powder and titanium powder and stir evenly, then add C 2 Cl 6Refining, mechanical stirring for 30mim, stop heating until the melt temperature is cooled to 720°C with the furnace, pouring, metal casting mold preheating 300°C, the achieved indicators: tensile strength 278Mpa, yield strength 112Mpa, elongation 7.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com