Preparation method for stably suspended and dispersed nano-zinc oxide slurry

A nano-zinc oxide, dispersed and stable technology, applied in the direction of cosmetic preparations, skin care preparations, cosmetics, etc., can solve the problems of easy agglomeration of nano-zinc oxide, and achieve the effect of solving the problem of agglomeration, preventing sedimentation, and reducing use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Weigh 4.144g of calcium hydroxide and 125mL of water into the reactor and stir, heat to 60°C and start to feed CO with a flow rate of 0.3L / min 2 Gas, after reacting for 10 minutes, add 22.4g of nano-zinc oxide, stop the reaction when the pH is 7, then filter, take the solid phase and dry to obtain calcium carbonate-loaded nano-zinc oxide.

[0029] (2) Weigh 28g calcium carbonate-loaded nano-zinc oxide, 2.8g attapulgite, 68.66g water, 0.14g dispersant SN-5040 and 0.4g defoamer, disperse evenly on a high-speed disperser, and then sand mill for 3 hours to obtain nano Zinc oxide paste.

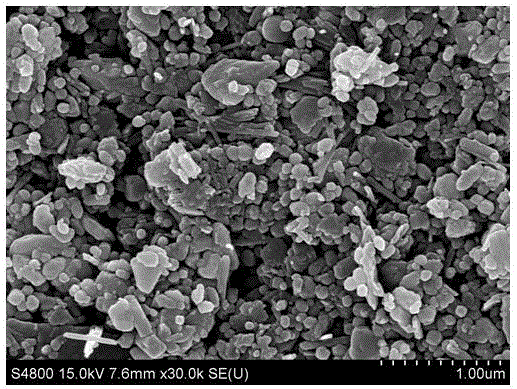

[0030] The nano-zinc oxide prepared in this embodiment is uniformly dispersed and does not agglomerate, and its microscopic appearance is shown in the attached figure 1 .

Embodiment 2

[0032] (1) Weigh 17.76g of calcium hydroxide powder, put 125mL of water into the reactor and stir, heat to 20°C and start to introduce CO with a flow rate of 0.5 L / min 2 Gas, after reacting for 10 minutes, add 24g of nano-zinc oxide, stop the reaction when the pH is 6, then filter, take the solid phase and dry to obtain calcium carbonate-loaded nano-zinc oxide.

[0033] (2) Weigh 48g of calcium carbonate-loaded nano-zinc oxide, 1.6g of attapulgite, 48.44g of water, 0.96g of dispersant SN-5040 and 1g of defoamer, disperse evenly on a high-speed disperser, and then sand mill for 3 hours to obtain nano-zinc oxide Zinc paste. The obtained nano-zinc oxide slurry has the same effect as that of Example 1.

Embodiment 3

[0035] (1) Weigh 2.55g of calcium hydroxide powder, put 125mL of water into the reactor and stir, heat to 80°C and start to introduce CO with a flow rate of 0.2L / min 2 Gas, after reacting for 10 minutes, add 34.55g of nano-zinc oxide, stop the reaction when the pH is 8, then filter, take the solid phase and dry to obtain calcium carbonate-loaded nano-zinc oxide.

[0036] (2) Weigh 38g of calcium carbonate-loaded nano-zinc oxide, 2g of attapulgite, 59.12g of water, 0.38g of dispersant SN-5040 and 0.5g of defoamer, disperse evenly on a high-speed disperser, and then sand mill for 3 hours to obtain nano-zinc oxide Zinc paste. The obtained nano-zinc oxide slurry has the same effect as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com