Method for preparing EVA elastomer

An elastomer and ethylene technology, applied in the field of preparing polymer materials, can solve the problems of high ethylene pressure, difficult to control, complicated process and equipment, complicated solvent system, etc., achieve high industrial application value, improve diffusion and initiation efficiency, chain transfer Constant low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

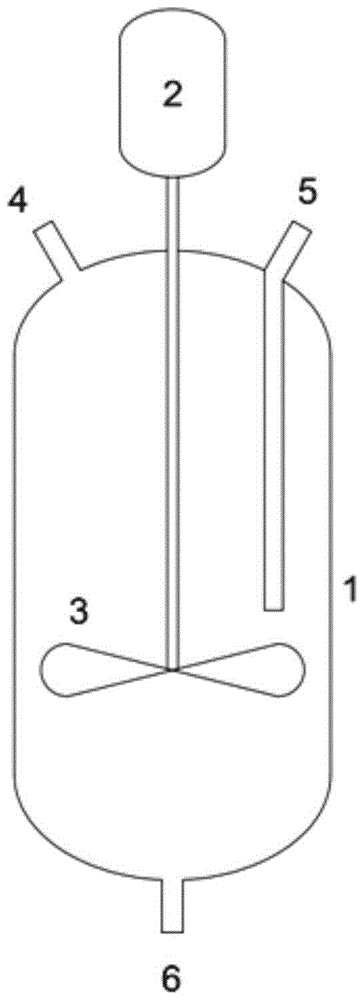

Image

Examples

Embodiment 1

[0027] In a single reactor, tert-butanol is used as the single solvent; the volume ratio of solvent to vinyl acetate is 2:1; the initiator is azobisisobutyronitrile, and the amount is 3.0wt% of vinyl acetate; polymerization temperature The temperature is 65°C, the ethylene pressure is 19.0 MPa, and the reaction time is 4 hours. Under this condition, the VAc content in the polymerized product was 49.7% by weight.

Embodiment 2

[0029] In a single reactor, tert-butanol is used as the single solvent; the volume ratio of solvent to vinyl acetate is 2:1; the initiator is azobisisobutyronitrile, and the amount is 3.0wt% of vinyl acetate; polymerization temperature The temperature is 65°C, the ethylene pressure is 17.0 MPa, and the reaction time is 4 hours. Under this condition, the VAc content in the polymerized product was 51.1 wt%.

Embodiment 3

[0031] In a single reactor, tert-butanol is used as the single solvent; the volume ratio of solvent to vinyl acetate is 2:1; the initiator is azobisisobutyronitrile, and the amount is 3.0wt% of vinyl acetate; polymerization temperature The temperature is 65°C, the ethylene pressure is 13.0MPa, and the reaction time is 4 hours. Under this condition, the VAc content in the polymerized product was 57.6% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com