Carrier system for water-soluble active ingredients

An active ingredient and water-soluble technology, which is applied in the field of sunscreen compositions of water-in-silicone inverse emulsions, can solve the problems of long-term stability of light filters such as difficult preparation and lack of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

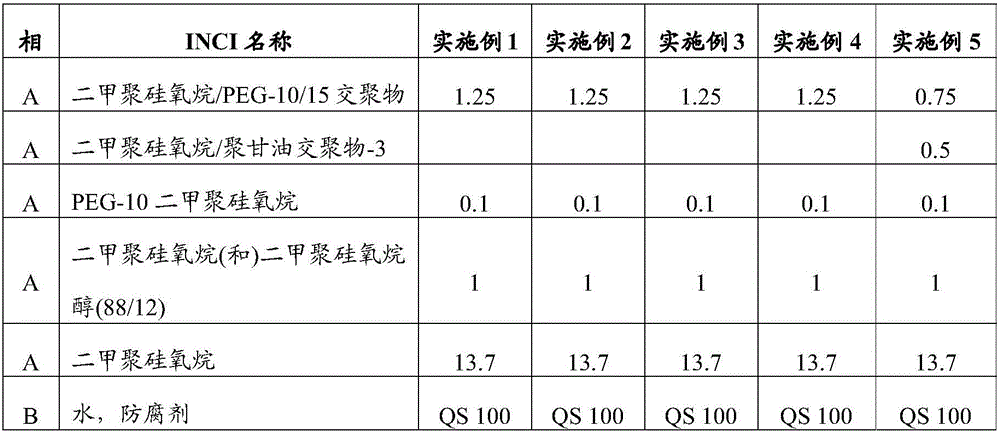

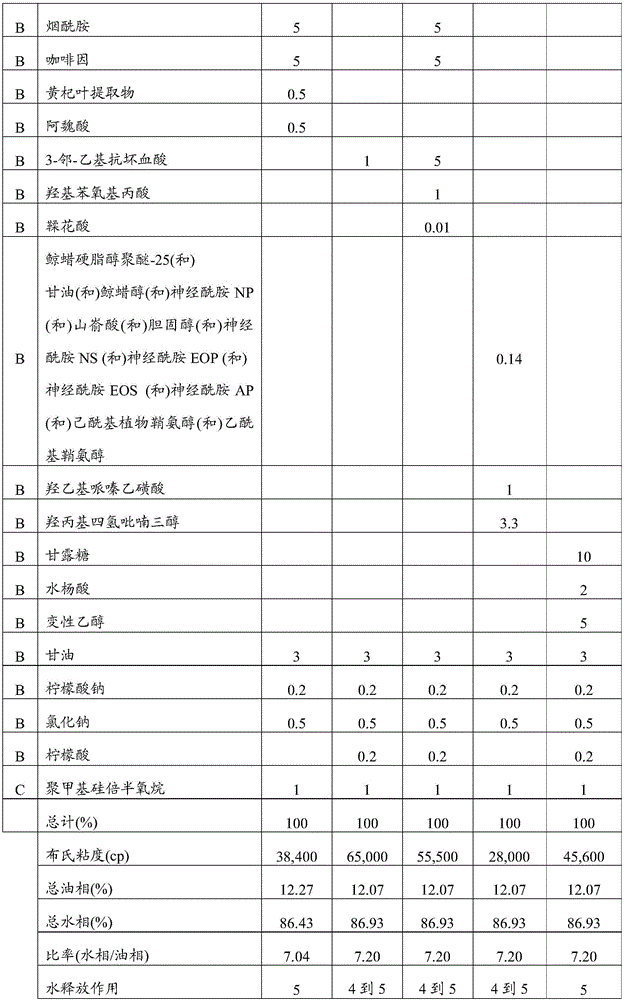

[0064] The preparation methods for each of the examples provided in Tables 1 and 2 were substantially the same. The examples in Tables 1 and 2 include inventive examples of emulsions incorporating high concentrations of water-soluble active ingredients and having water-releasing effects. The examples in Tables 3 and 4 are comparative examples illustrating the lack of emulsion stability and / or stabilization of active ingredients in typical water-in-oil emulsions.

[0065] In each example (inventive example and comparative example), the viscosity of the emulsion was measured using a Brookfield viscometer using a Helipath spindle T-D with a speed set at 10 rpm. The spindle is oscillated in the test sample and the measurement is taken after one minute.

[0066] The water release effect of each example was measured by placing about 0.2 g of the cosmetic composition on the back of the hand and then applying it by gently swirling with the middle and ring fingers of the other hand. ...

Embodiment 13-17

[0087]

[0088]

[0089] In preparing each of the examples in Table 5, the following method was used.

[0090] The components of Phase B (aqueous phase) were mixed together in a side beaker with a rotor / stator stirrer until all solids dissolved, forming a clear solution. If desired, Phase B (aqueous phase) can be heated slowly to about 40-45°C until all solids are dissolved. The ingredients of phase A (oil phase) were placed in the main beaker and mixed well with a propeller stirrer at about 600-700 RPM, then set aside. Slowly add the mixture of water phase (Phase B) ingredients to the combined Phase A (oil phase) ingredients and mix using a propeller mixer for 10-15 minutes for batches of about 1 kg. As the viscosity of the mixture increased, the stirring rate was increased from 700 rpm to about 1200 rpm. As the water phase is mixed into the oil phase, a water-in-oil emulsion forms. Optionally, powder is added to the batch and mixed into the water-in-oil emulsion.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com