Nano magnesium sulfide loaded graphene composite material, and preparation method thereof

A composite material and graphene technology, applied in the direction of electrochemical generators, electrical components, battery electrodes, etc., can solve the problems of cycle performance attenuation, uneven particle size, capacity decline, etc., and achieve cycle stability, lithium storage specific capacity, and The effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Add 2.0 ml organic magnesium, 30.0 mg graphene, and 40 ml cyclohexane into an autoclave, add hydrogen at 20 bar, heat to 200 °C, and react for 8 h to obtain nano-magnesium hydride particles uniformly grown on the surface of graphene ;

[0019] (2) Place 60 mg of graphene-supported nano-magnesium hydride and 88 mg of sulfur powder in quartz boats respectively, and under the protection of nitrogen atmosphere, carry out a temperature program in a tube furnace at 5°C / min to 300°C for the vulcanization reaction. 5 h to obtain graphene-supported nano-magnesium sulfide;

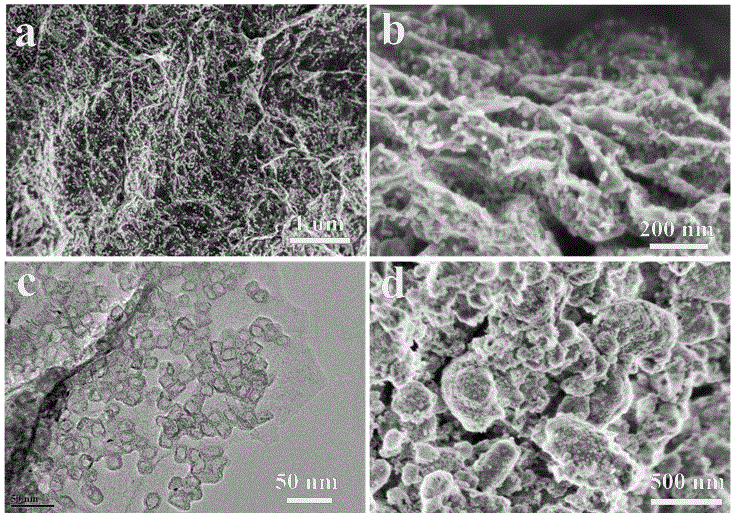

[0020] (3) Do XRD test and SEM analysis on the final sample, such as figure 1 and figure 2 shown;

[0021] (4) Electrochemical performance test of the graphene-supported nano-magnesium sulfide composite negative electrode material prepared in Example 1:

[0022] Add composite materials: conductive carbon: PVDF ratio of 80:10:10 to make slurry, evenly spread on the copper sheet and dry in vacuum at 12...

Embodiment 2

[0024] (1) Add 2.0 ml organic magnesium, 40.0 mg graphene, and 40 ml cyclohexane into an autoclave, add hydrogen at 20 bar, heat to 200 °C, and react for 8 h to obtain nano-magnesium sulfide particles uniformly grown on the surface of graphene ;

[0025] (2) Place 40 mg of graphene-supported nano-magnesium hydride and 35 mg of sulfur powder in quartz boats respectively, and under the protection of nitrogen atmosphere, carry out a temperature program in a tube furnace at 6 °C / min to 350 °C for vulcanization reaction 4 h to obtain graphene-supported nano-magnesium sulfide;

[0026] (3) Electrochemical performance test of the graphene-loaded nano-magnesium sulfide composite negative electrode material prepared in Example 2:

[0027] Add composite materials, conductive carbon, and PVDF slurry (mass ratio is 80:10:10), evenly spread on copper sheet, and vacuum dry at 120 °C for 24 h to prepare electrodes. Take 2025 button battery case, the separator is PP / PE / PP, and use 1 mol / L L...

Embodiment 3

[0029] (1) Add 2.0 ml organic magnesium, 40.0 mg graphene, and 40 ml cyclohexane into an autoclave, add hydrogen at 30 bar, heat to 150 °C, and react for 8 h to obtain nano-magnesium sulfide particles uniformly grown on the surface of graphene ;

[0030] (2) Place 40 mg of graphene-supported nano-magnesium hydride and 25 mg of sulfur powder in a quartz boat, and under the protection of a nitrogen atmosphere, carry out a temperature program in a tube furnace at 5 °C / min to 350 °C for the vulcanization reaction. 6 h to obtain graphene-supported nano-magnesium sulfide;

[0031] (3) Electrochemical performance test of the graphene-loaded nano-magnesium sulfide composite negative electrode material prepared in Example 2:

[0032] Add composite materials, conductive carbon, and PVDF slurry (mass ratio is 80:10:10), evenly spread on copper sheet, and vacuum dry at 120 °C for 24 h to prepare electrodes. Take 2025 button battery case, the separator is PP / PE / PP, and use 1 mol / L LiPF ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com