Application of carbon dot @ inorganic oxide to preparation of anti-ultraviolet product

An inorganic oxide and anti-ultraviolet technology, which is applied in the field of carbon dots, can solve the problems of limiting the use range of UV absorbers, single pop range, endangering health and safety, etc., and achieves the reduction of ultraviolet transmittance, simple production process, good The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] Take 60ml of triethanolamine, add it to 30ml of deionized water, stir at 80°C for 30min, then add 0.40g of CTAB (cetyltrimethylammonium bromide) and 0.2g of sodium salicylate in sequence, continue stirring for 1.5h, then Add 3ml of tetraethyl orthosilicate, then add 200μl of carbon dot solution (50%) or 100μg of solid carbon dots, and react for 12h under stirring conditions. Carbon dots@SiO 2 composite material.

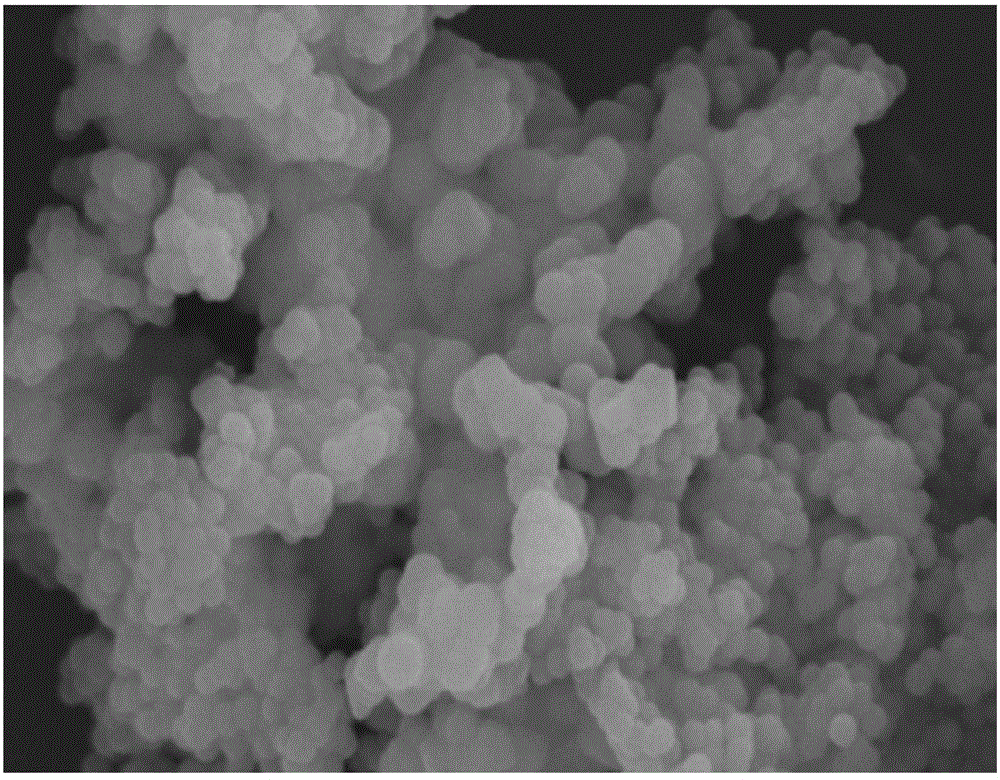

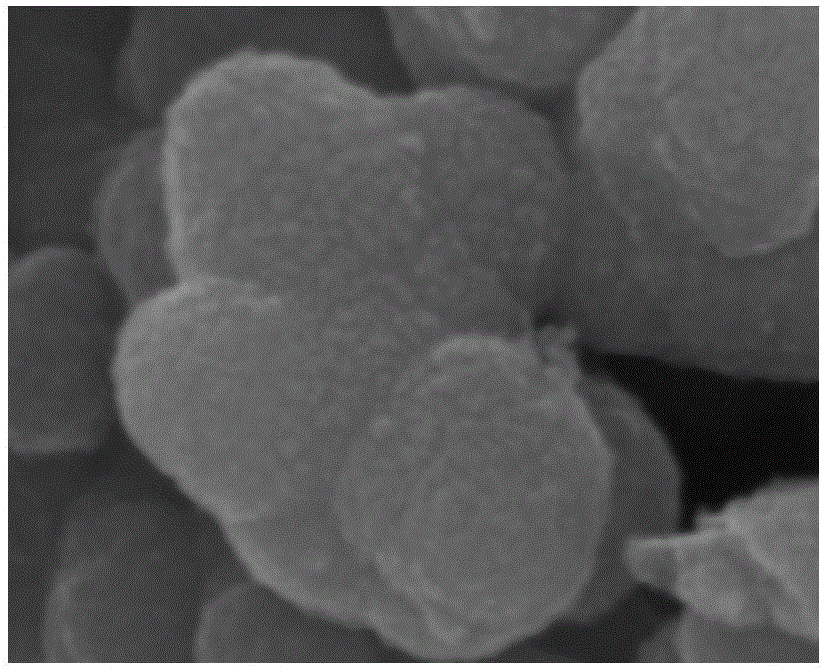

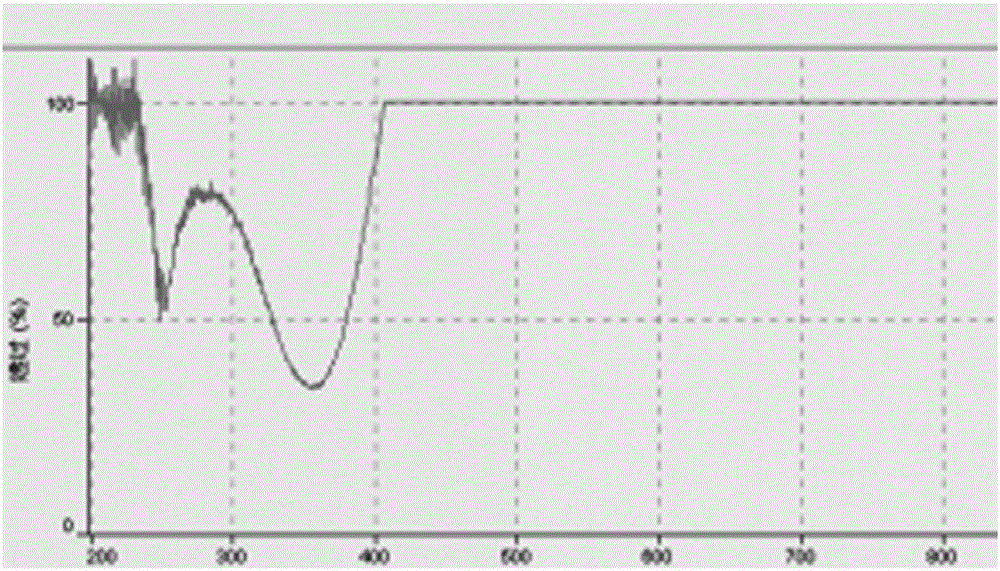

[0023] For the prepared carbon dots@SiO 2 The composite material was scanned by electron microscope, and the results were as follows: figure 1 with figure 2 shown. Depend on figure 1 with figure 2 It can be seen that the prepared carbon dots@SiO 2 The composite material has good dispersion and uniform particle size distribution. figure 2 For high-resolution scanning electron microscopy, SiO can be clearly seen 2 The crystal of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com