A kind of 2,6-position substituted bodipy organic dye sensitizer and preparation method thereof

An organic dye and sensitizer technology, applied in the field of dye-sensitized solar cell materials, can solve the problems of high price and limited resources, and achieve the effects of low production cost, simple purification and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] (1) Synthesis of Dye 1:

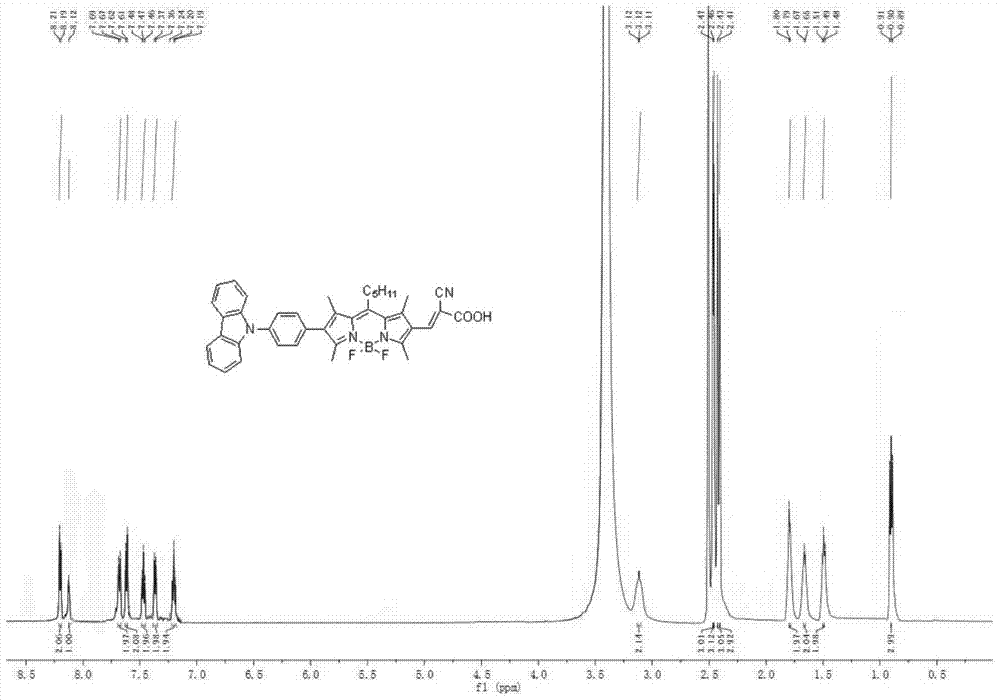

[0111] Intermediate 14 (180mg, 0.3mmol), cyanoacetic acid (50mg, 0.6mmol), acetonitrile (20mL), chloroform (20mL) and piperidine (0.2mL) were sequentially added to a 100mL three-neck flask, and under argon protection, Reflux at 80°C for 24h. After cooling to room temperature, the reaction solution was poured into 50 mL of dichloromethane for dilution, washed 3 times with water (3×50 mL), and the organic phase was dried over anhydrous MgSO4. The solvent was removed by rotary evaporation, and the crude product was subjected to silica gel column chromatography (dichloromethane:methanol=10:1) to obtain 156 mg of dark red solid powder with a yield of 80%. 1 H NMR (400MHz, CDCl 3 )δ10.15(s,1H),8.17(d,J=7.4Hz,2H),7.70(d,J=7.2Hz,2H),7.51(s,2H),7.46(d,J=6.5Hz, 4H),7.32(s,2H),3.17(t,2H),2.83(s,3H),2.81(s,3H),2.63(s,3H),2.50(s,3H),1.74(s,2H ), 1.54(d, J=4.6Hz, 2H), 1.43(d, J=6.5Hz, 2H), 0.96(t, 3H). 13 C NMR (101MHz, CDCl 3 )δ:186.34,158.42,149.58,1...

Embodiment 2

[0113] (2) Synthesis of Dye 2:

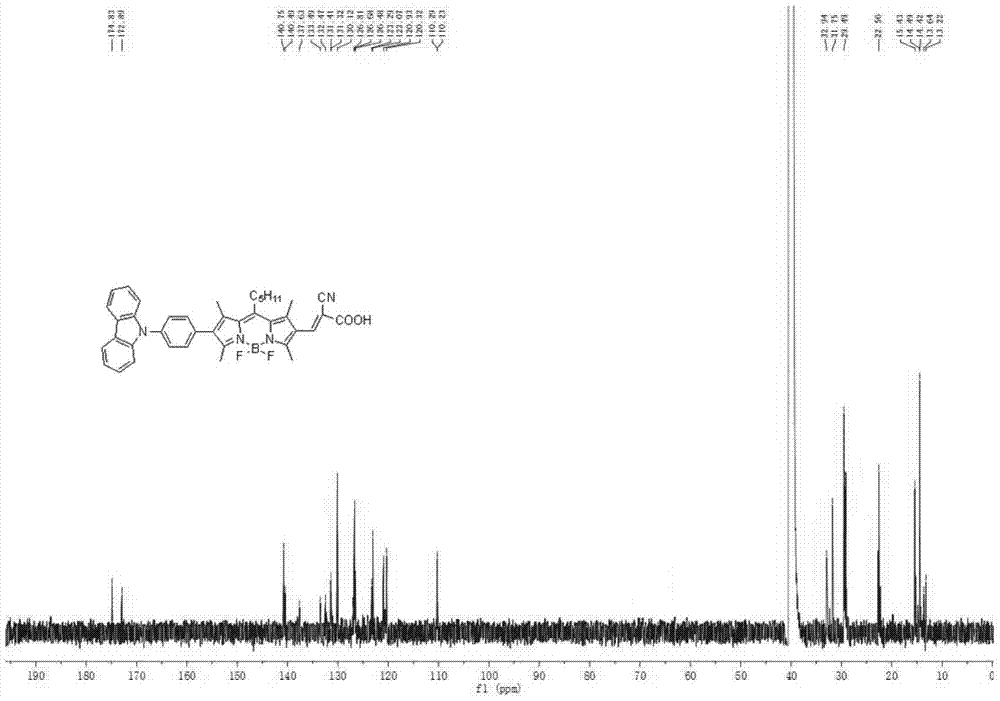

[0114] 150 mg of purple-red solid powder was obtained by a method similar to that of dye 1, and the yield was 78%. 1 H NMR (600MHz, DMSO) δ: 8.21(d, J=7.7Hz, 2H), 8.12(s, 1H), 7.67-7.69(d, J=7.7Hz, 2H), 7.62(d, J=7.7Hz ,2H),7.47(d,J=9.8Hz,2H),7.36(d,J=7.2Hz,2H),7.19-7.24(t,J=7.3Hz,2H),3.12(s,2H),2.47 (s,3H),2.46(s,3H),2.43(s,3H),2.41(s,3H),1.79(m,2H),1.65(m,2H),1.49(m,2H),0.90( t,J=7.0Hz,3H). 13 C NMR(151MHz,DMSO)δ:174.83,172.89,140.75,140.49,137.63,133.49,132.47,131.41,131.32,130.12,126.81,126.68,126.48,123.29,123.07,120.93,120.32,110.29,110.23,32.94,31.75 , 29.49, 22.56, 15.43, 14.49, 14.42, 13.64, 13.22. MALDI-TOF-MS, m / z: calcd for C 42 h 49 BF 2 N 4 o 2 [M] + :690.400,found:690.251.

Embodiment 3

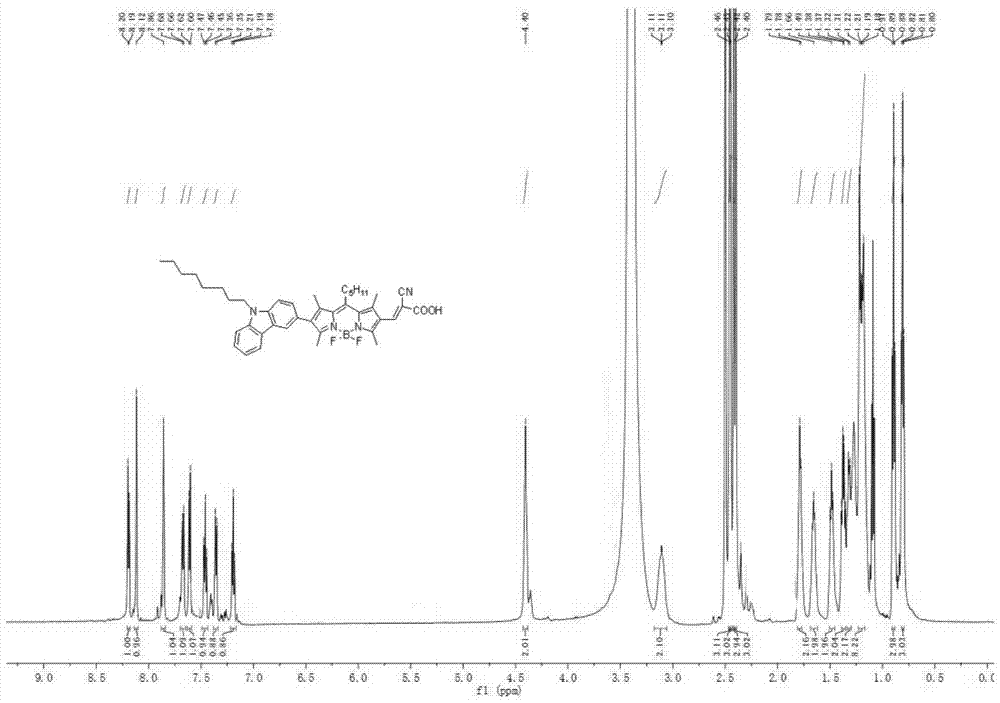

[0116] Synthesis of Dye 3

[0117] 145 mg of purple-red solid powder was obtained by a method similar to that of dye 1, and the yield was 75%. 1 H NMR (600MHz, DMSO) δ: 8.20 (d, J = 6.5Hz, 1H), 8.17 (d, J = 6.8Hz, 1H), 7.91 (s, 1H), 7.60–7.55 (m, 2H), 7.46 (t,J=7.3Hz,1H),7.21(t,J=7.1Hz,1H),7.09(d,J=6.7Hz,1H),4.41(s,2H),3.09(s,2H),2.48 (s,6H),2.41(s,6H),1.76(s,2H),1.65(s,2H),1.48(s,2H),1.37(d,J=6.6Hz,2H),1.23–1.13( m,10H),0.90(t,J=6.8Hz,3H),0.78(t,J=6.6Hz,3H). 13 C NMR(151MHz,DMSO)δ:155.41,151.10,148.38,140.81,140.66,139.06,137.58,135.96,132.25,131.06,130.20,126.32,126.03,122.34,121.75,121.27,120.83,120.72,119.31,111.52,109.77 ,51.60,32.81,32.35,31.57,29.26,29.23,29.11,29.08,27.05,22.50,22.29,15.40,14.77,14.35,14.32,13.92,13.13. MALDI-TOF-MS, m / z: calcd for C 42 h 49 BF 2 N4 o 2 [M] + :690.400,found:690.612.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com