Preparation method of polymer fiber-based ZnO nanowire fiber

A technology of polymers and nanowires, which is applied in the field of fiber manufacturing, can solve the problems of inability to obtain mechanical properties, and achieve the effects of good mechanical properties, good surface friction resistance, and stable shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

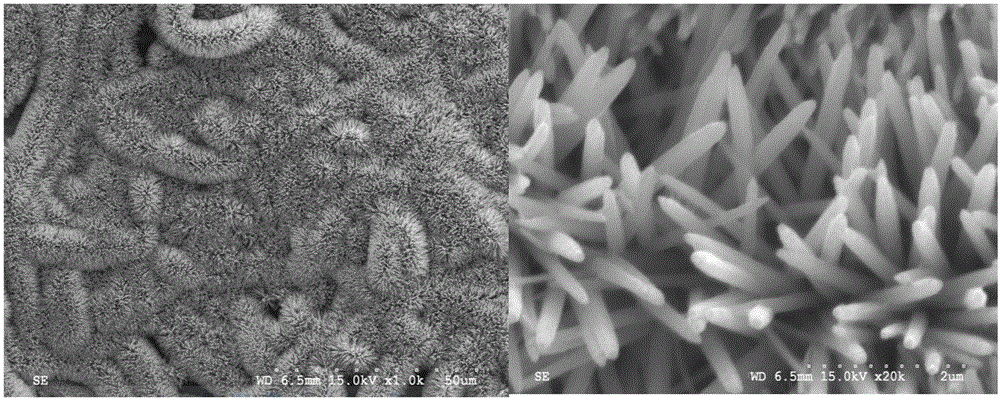

Embodiment 1

[0024] A preparation method of polymer fiber-based ZnO nanowire fiber, comprising the following steps:

[0025] (1) Mixing PVDF and zinc acetate with a concentration of 20%, the mass fraction of zinc acetate is 20%, and heating and stirring for 5 hours at a temperature of 90°C to obtain an electrospinning solution; transfer the solution into a 10mL syringe, then fix the syringe on the syringe pump, control the electrospinning voltage to 20KV, and the distance from the receiving device to the spinning needle to be 18cm, and perform electrospinning in a single-needle electrospinning device to obtain and nanofibers of ZnO precursors;

[0026] (2) The nanofibers obtained in step (1) are subjected to low-temperature heat treatment at a temperature of 130° C., and the holding time is 6 hours under the condition of sufficient oxygen to obtain nanofibers with uniform distribution of ZnO nanoparticles inside, while the polymer fibers still maintain their Performance, there will be no ...

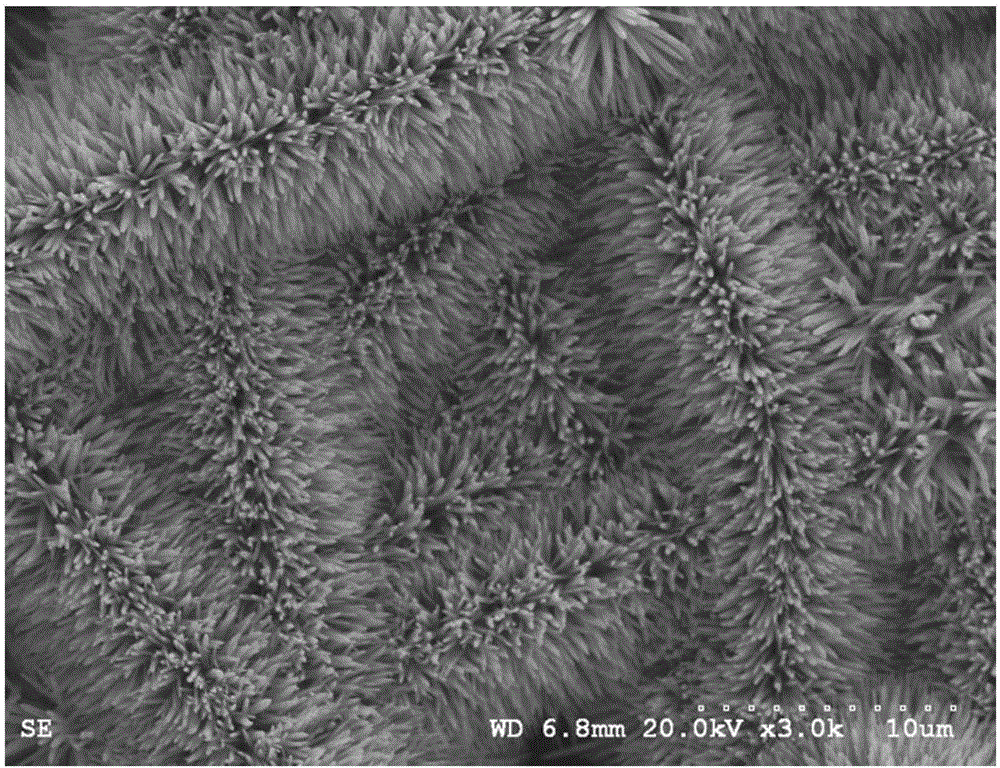

Embodiment 2

[0029] A preparation method of polymer fiber-based ZnO nanowire fiber, comprising the following steps:

[0030] (1) Mix polyacrylonitrile (PAN) with a concentration of 10% and zinc acetate, the mass fraction of zinc acetate is 6%, and heat and stir at a temperature of 80°C for 3 hours to obtain an electrospinning solution ; transfer the solution to a 10mL syringe, then fix the syringe on the syringe pump, control the electrospinning voltage to 17KV, and the distance from the receiving device to the spinning needle is 20cm, and carry out electrospinning in a single-needle electrospinning device silk, resulting in nanofibers containing polymer and ZnO precursors;

[0031] (2) The polyacrylonitrile (PAN) nanofiber obtained in step (1) is subjected to low-temperature heat treatment, the temperature is 180° C., under the condition of sufficient oxygen, the holding time is 10 hours, and the nanofiber with uniform ZnO nanoparticle distribution inside is obtained, and at the same time...

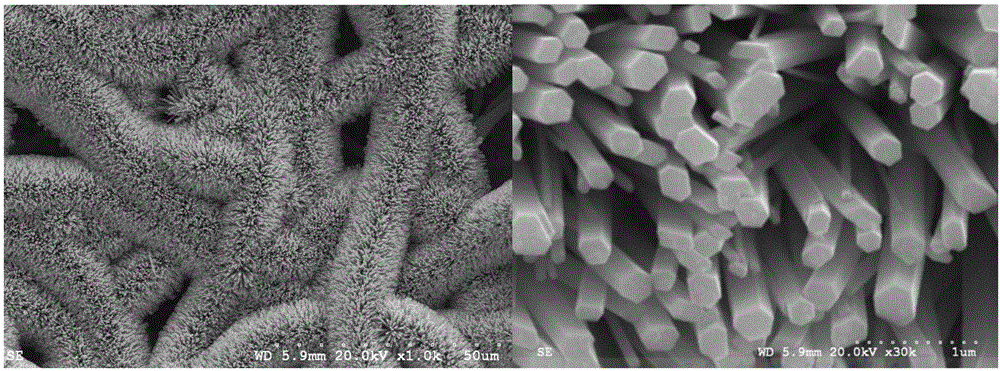

Embodiment 3

[0034] A preparation method of polymer fiber-based ZnO nano wire fiber, comprising the following steps:

[0035] (1) Mix PES and zinc acetate with a concentration of 30%, the mass fraction of zinc acetate is 15%, and heat and stir for 4 hours at a temperature of 70°C to obtain an electrospinning solution; transfer the solution into a 10mL syringe, then fix the syringe on the syringe pump, control the electrospinning voltage to 23KV, and the distance from the receiving device to the spinning needle to be 20cm, perform electrospinning in a single-needle electrospinning device, and obtain nanofibers of PES and ZnO precursors;

[0036] (2) The nanofibers obtained in step (1) are subjected to low-temperature heat treatment at a temperature of 140°C. In the case of sufficient oxygen, the holding time is 16 hours to obtain nanofibers with uniform distribution of ZnO nanoparticles inside, while the PES fibers still maintain Its performance will not have any changes in composition and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com