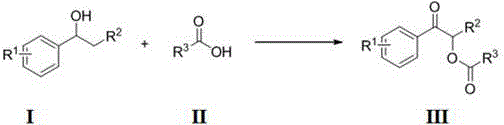

Method for preparing alpha-acyloxy ketone compound

A technology for acyloxyketones and compounds, which is applied in the field of preparation of α-acyloxyketone compounds, can solve the problems of restricting wide application, and achieve the effects of high atom economy, high yield and wide substrate adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

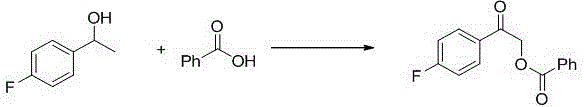

Embodiment 1

[0040]

[0041] At room temperature, 1-phenylpropanol (0.136 g, 1 mmol), benzoic acid (0.183 g, 1.5 mmol), NBS (0.356 g, 2 mmol) and 1,4-dioxo Hexacyclic (2 mL). Stir at 60°C for 1 hour, then add DBU (0.304 g, 2 mmol) and continue the reaction for 2 hours (reaction detected by TLC). Then, the reaction was stopped and concentrated under reduced pressure to obtain a crude product. Finally, it was washed with a mixed eluent of petroleum ether and ethyl acetate, and flash column chromatography (silica gel column) obtained the corresponding product α-acyloxyketone compound (yellow solid 0.251 g, yield 99%).

[0042] 1 H NMR (CDCl 3 , 400 MHz, ppm): δ8.12 (d, J = 7.1 Hz, 2H), 8.03 (d, J =7.1 Hz, 2H), 7.63-7.58 (m, 2H), 7.53-7.45 (m, 4H), 6.24 (q, J = 7.0 Hz, 3H), 1.70 (d, J = 7.0 Hz, 3H); 13 C NMR (CDCl 3 , 100 MHz, ppm): δ196.7, 166.0, 134.5,133.6, 133.3, 129.9, 129.5, 128.8, 128.5, 128.4, 71.9, 17.2; HRMS calc. 16 h 14 o 3 Na (M+Na) + , 277.0841; found, 277.084...

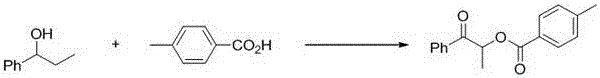

Embodiment 2

[0044]

[0045] At room temperature, 4-methyl-1-phenylpropanol (0.15 g, 1 mmol), benzoic acid (0.183 g, 1.5 mmol), NBS (0.356 g, 2 mmol) and 1 , 4-dioxane (2 mL). Stir at 60°C for 1 hour, then add DBU (0.304 g, 2 mmol) and continue the reaction for 4 hours (reaction detected by TLC). Then, the reaction was stopped and concentrated under reduced pressure to obtain a crude product. Finally, it was washed with a mixed eluent of petroleum ether and ethyl acetate, and flash column chromatography (silica gel column) obtained the corresponding product α-acyloxyketone compound (white solid 0.239g, yield 89%).

[0046] 1 H NMR (CDCl 3 , 400 MHz, ppm): δ8.11 (d, J = 7.0 Hz, 2H), 7.93 (d, J =8.2 Hz, 2H), 7.60 (t, J = 7.4 Hz, 1H), 7.47 (t, J = 7.9 Hz, 2H), 7.31 (d, J =8.0 Hz,2H), 6.22 (q, J = 7.0 Hz, 1H), 2.44 (s, 3H), 1.69 (d, J = 7.0 Hz, 3H); 13 C NMR (CDCl 3 for C 17 h 16 o 3 Na (M+Na) + , 291.0997; found, 291.0999.

Embodiment 3

[0048]

[0049] At room temperature, 1-phenylethanol (0.122 g, 1 mmol), benzoic acid (0.183 g, 1.5 mmol), NBS (0.356 g, 2 mmol) and 1,4-dioxane were sequentially added to a 50 mL round bottom flask ring (2 mL). Stir at 60°C for 1 hour, then add DBU (0.304 g, 2 mmol) and continue the reaction for 4 hours (reaction detected by TLC). Then, the reaction was stopped and concentrated under reduced pressure to obtain a crude product. Finally, it was washed with a mixed eluent of petroleum ether and ethyl acetate, and flash column chromatography (silica gel column) obtained the corresponding product α-acyloxyketone compound (white solid 0.211g, yield 88%).

[0050] 1 H NMR (CDCl 3 , 400 MHz, ppm): δ8.17 (d, J = 7.1 Hz, 2H), 8.00 (d, J =7.1 Hz, 2H), 7.66-7.61 (m, 2H), 7.56-7.48 (m, 4H), 5.61 (s, 2H); 13 C NMR (CDCl 3 , 100 MHz, ppm): δ192.3, 166.0, 134.4, 133.9, 133.3, 130.0, 128.9,128.5, 127.9, 66.5; HRMS calc. for C 15 h 12 o 3 Na (M+Na) + , 263.0684; found, 263.0685....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com