Chloride-free cement grinding aid

A technology of cement grinding aids and alcohol amines, applied in the field of cement additives, can solve the problems of insignificant strengthening effect, high cost of grinding aids, and affecting the service life of buildings, so as to reduce energy consumption and achieve good grinding aid effect , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

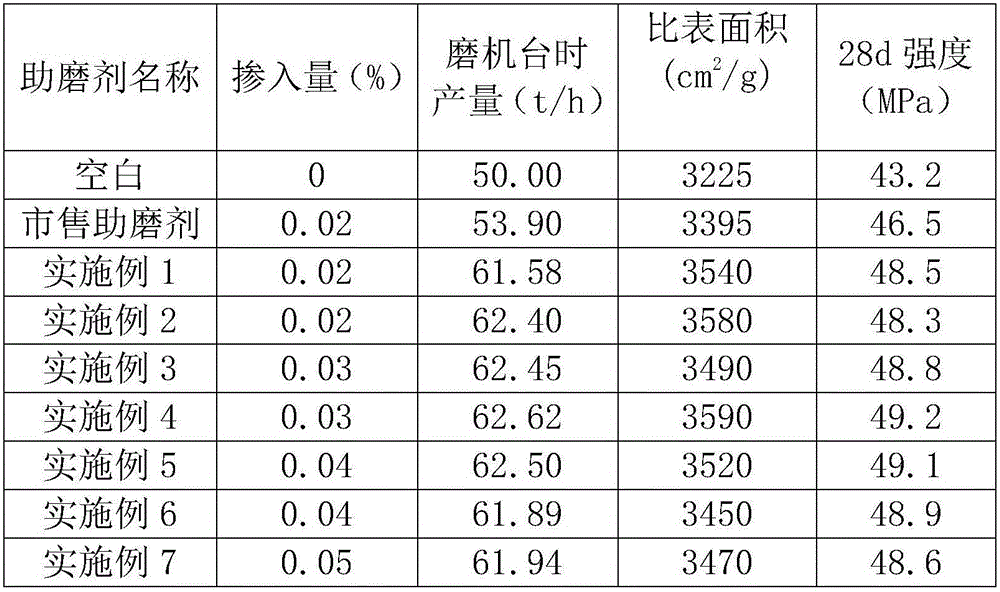

Examples

Embodiment 1

[0027] Chlorine-free cement grinding aid, made of the following raw materials in parts by weight: 28 parts of triethanolamine, 22 parts of alkylphenol polyoxyethylene ether, 10 parts of hexamethylenetetramine, 11 parts of N-acetylimidazole, polyethylene 1 part of diol, 7 parts of molasses.

[0028] The preparation method of above-mentioned chlorine-free cement grinding aid is:

[0029] 1) take each component by weighing;

[0030] 2) adding triethanolamine, alkylphenol polyoxyethylene ether and hexamethylenetetramine to the reactor in sequence;

[0031] 3) Keep the reaction kettle at 70°C and stir for 250 minutes;

[0032] 4) Lower the temperature to 60°C, continue to add N-acetylimidazole, polyethylene glycol and molasses in sequence, and stir for 180 minutes;

[0033] 5) Cool down to room temperature, pack, and get ready.

Embodiment 2

[0035] Chlorine-free cement grinding aid, made of the following raw materials in parts by weight: 31 parts of diisopropylethanolamine, 20 parts of alkylphenol polyoxyethylene ether, 11 parts of hexamethylenetetramine, and 10 parts of N-acetylimidazole , 2 parts of polyethylene glycol, 6 parts of molasses.

[0036] The preparation method of above-mentioned chlorine-free cement grinding aid is:

[0037] 1) take each component by weighing;

[0038] 2) adding diisopropylethanolamine, alkylphenol polyoxyethylene ether and hexamethylenetetramine to the reactor in sequence;

[0039] 3) Keep the reaction kettle at 71°C and stir for 230 minutes;

[0040] 4) Lower the temperature to 61°C, continue to add N-acetylimidazole, polyethylene glycol and molasses in sequence, and stir for 170 minutes;

[0041] 5) Cool down to room temperature, pack, and get ready.

Embodiment 3

[0043] Chlorine-free cement grinding aid, made of the following raw materials in parts by weight: 34 parts of triisopropanolamine, 18 parts of alkylphenol polyoxyethylene ether, 12 parts of hexamethylenetetramine, and 9 parts of N-acetylimidazole , 3 parts of polyethylene glycol, 5 parts of molasses.

[0044] The preparation method of above-mentioned chlorine-free cement grinding aid is:

[0045] 1) take each component by weighing;

[0046] 2) adding triisopropanolamine, alkylphenol polyoxyethylene ether and hexamethylenetetramine to the reactor in sequence;

[0047] 3) Keep the reaction kettle at 72°C and stir for 210min;

[0048] 4) Lower the temperature to 62°C, continue to add N-acetylimidazole, polyethylene glycol and molasses in sequence, and stir for 150 minutes;

[0049] 5) Cool down to room temperature, pack, and get ready.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com