Ultrathin metal oxide nanometer sheet preparation method and application thereof

A technology of nanosheets and oxides, which is applied in the field of copper oxide nanosheets to induce ultra-thin metal oxide nanosheets, which can solve the problems of unstable electrochemical performance, uneven thickness of ultra-thin two-dimensional nanosheets, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The invention provides a method for preparing metal oxide nanosheets, comprising the following steps:

[0059] A) The soluble metal source, copper oxide nanosheets and water are mixed to form a reaction solution, and then hydrothermal reaction is carried out after standing still to obtain metal oxide nanosheets.

[0060] The present invention has no special restrictions on the standing conditions, and the conventional standing conditions well known to those skilled in the art can be used. Those skilled in the art can select and adjust according to actual production conditions, raw material conditions and product requirements. The standing time of the invention is preferably 1-48h, more preferably 5-45h, more preferably 10-40h, most preferably 20-30h.

[0061] The present invention has no special limitation on the conditions of the hydrothermal reaction, the conventional hydrothermal reaction conditions well known to those skilled in the art can be used, and those skille...

Embodiment 1

[0088] 1. Synthesis of copper oxide nanosheets

[0089] Weigh 3.0g of copper sulfate pentahydrate and 0.6g of polyvinylpyrrolidone and dissolve them in 300mL of water, dilute 0.93mL of ammonia water (mass fraction 25-28%) to 90mL with water, and after the copper sulfate and polyvinylpyrrolidone are dissolved, dilute the diluted Mix ammonia water with it, stir for 15 minutes, dissolve 2.4g of sodium hydroxide in 10mL of water to form a sodium hydroxide solution, slowly add the sodium hydroxide solution dropwise to the above mixed solution, then stir the reaction solution continuously for 3 days, centrifuge and wash with water one time standby;

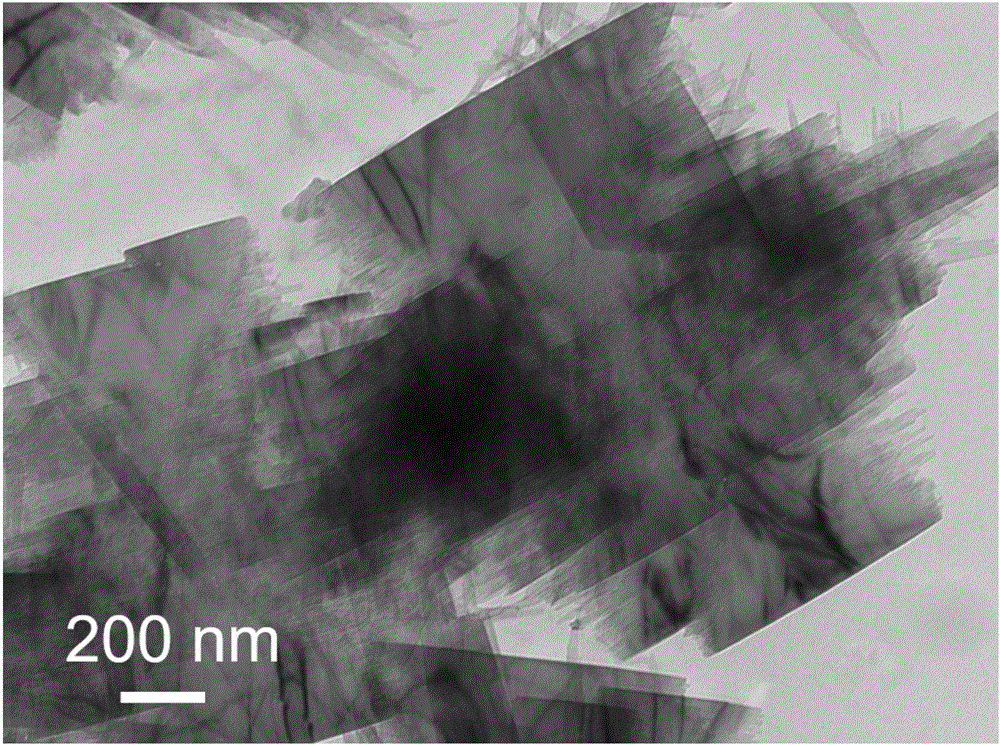

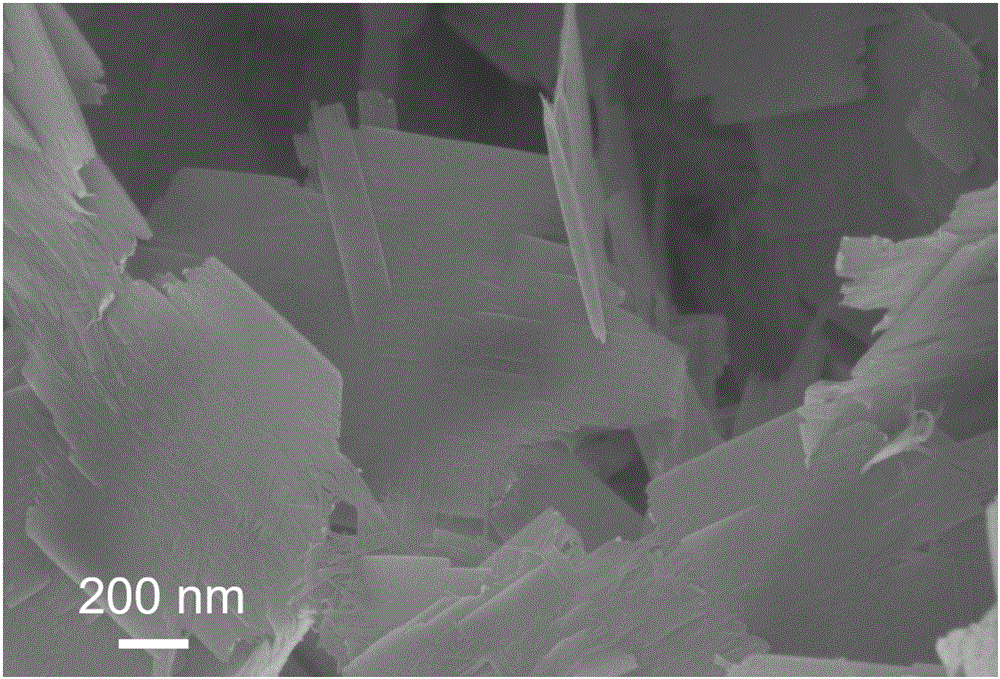

[0090] The copper oxide nanosheets prepared in Example 1 of the present invention were characterized.

[0091] see figure 1 , figure 1 Transmission electron micrograph of the copper oxide nanosheets prepared in Example 1 of the present invention. see figure 2 , figure 2 A scanning electron micrograph of the copper oxide nanoshee...

Embodiment 2

[0099] 1. Synthesis of copper oxide nanosheets

[0100]Weigh 3.0g of copper sulfate pentahydrate and 0.6g of polyvinylpyrrolidone and dissolve them in 300mL of water, dilute 0.93mL of ammonia water (mass fraction 25-28%) to 90mL with water, and after the copper sulfate and polyvinylpyrrolidone are dissolved, dilute the diluted Mix ammonia water with it, stir for 15 minutes, dissolve 2.4g of sodium hydroxide in 10mL of water to form a sodium hydroxide solution, slowly add the sodium hydroxide solution dropwise to the above mixed solution, and then continuously stir the reaction solution for 3 days, then centrifuge and wash with water one time standby;

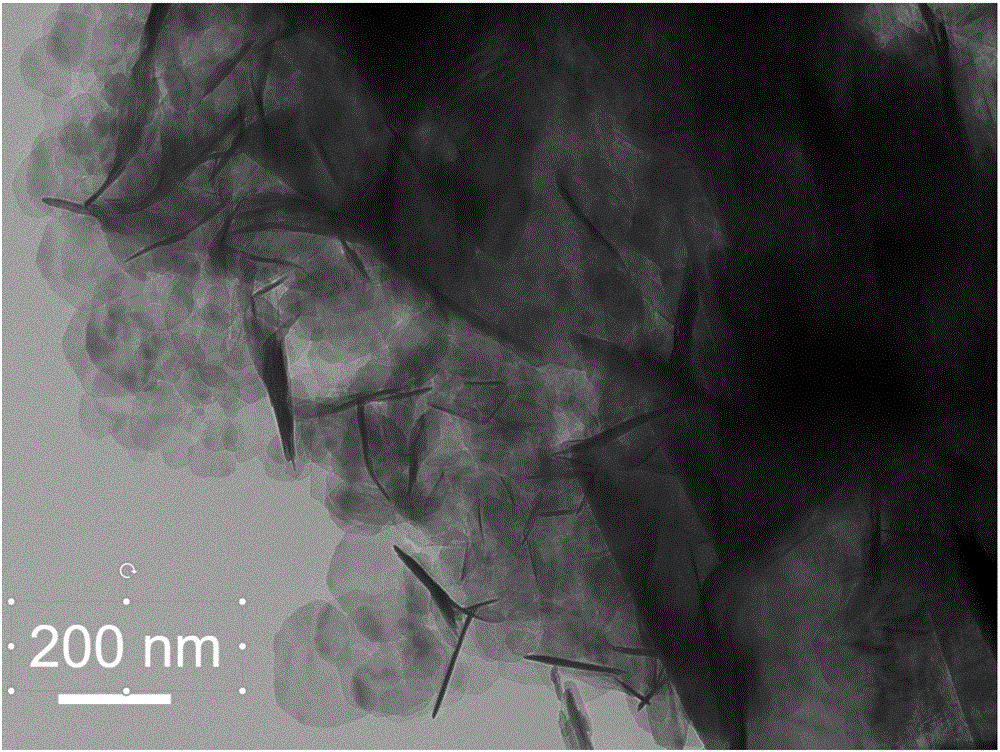

[0101] 2. Preparation of ultrathin Fe by induction of copper oxide nanosheets 2 o 3 Nanosheets

[0102] Sonicate 30 mL of copper oxide nanosheet aqueous solution with a concentration of 1 mg / mL for 20 min, and mix it with 5 mL of ferrous chloride solution with a concentration of 0.024 mol / L (before ferrous chloride is added t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com