Seven-layer melt-coextrusion stone paper and preparation method therefor

A stone paper and co-extrusion technology, applied in chemical instruments and methods, laminated, layered products, etc., can solve the problems of unstable stone paper product quality, difficulty in large-scale promotion and application, and poor printing adaptability, etc., to achieve effective It is conducive to market promotion and application, solves the problem of poor hygroscopicity and printing adaptability, and improves the effect of ink absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

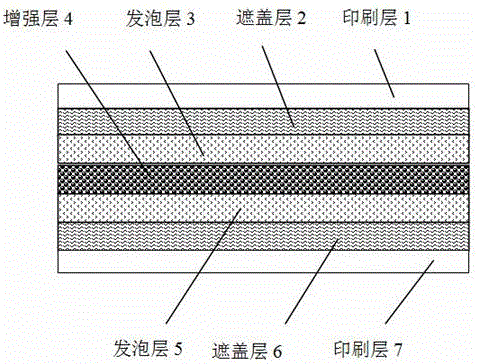

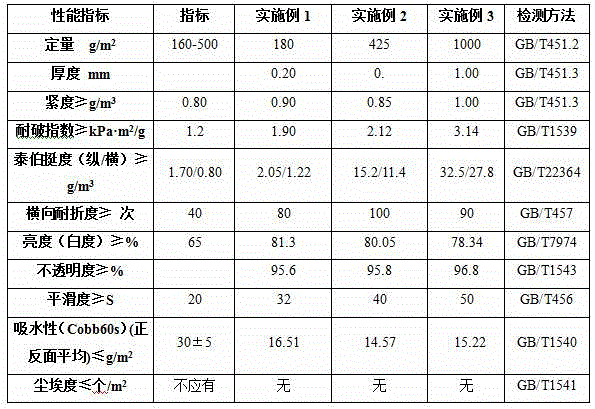

[0049] Seven-layer melted co-extruded stone paper, including a reinforcing layer, and a foam layer, a cover layer and a printing layer arranged on the two outer surfaces of the reinforced layer in sequence from the inside to the outside; the total thickness of the seven-layer melted co-extruded stone paper The total thickness of the printing layer accounts for 10% of the total thickness of the seven-layer melt co-extruded stone paper, the total thickness of the cover layer accounts for 10% of the total thickness of the seven-layer melt co-extruded stone paper, and the total thickness of the foam layer It accounts for 70% of the total thickness of the seven-layer melt co-extruded stone paper, and the reinforcing layer accounts for 10% of the total thickness of the seven-layer melt co-extruded stone paper.

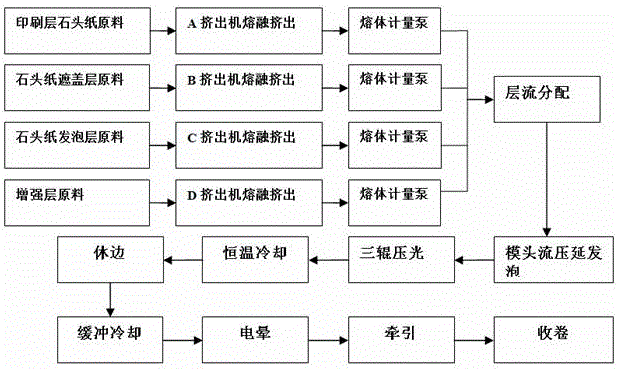

[0050] The preparation method of seven-layer melting co-extruded stone paper, through the following steps:

[0051] (1) Prepare the printing layer:

[0052] Raw materials a...

Embodiment 2

[0069] Seven-layer melted co-extruded stone paper, including a reinforcing layer, and a foam layer, a cover layer and a printing layer arranged on the two outer surfaces of the reinforced layer in sequence from the inside to the outside; the total thickness of the seven-layer melted co-extruded stone paper The total thickness of the printing layer accounts for 15% of the total thickness of the seven-layer melt co-extruded stone paper, the total thickness of the cover layer accounts for 15% of the total thickness of the seven-layer melt co-extruded stone paper, and the total thickness of the foam layer It accounts for 60% of the total thickness of the seven-layer melt co-extruded stone paper, and the reinforcing layer accounts for 10% of the total thickness of the seven-layer melt co-extruded stone paper.

[0070] The preparation method of seven-layer melting co-extruded stone paper, through the following steps:

[0071] (1) Prepare the printing layer:

[0072] Raw materials a...

Embodiment 3

[0089] Seven-layer melted co-extruded stone paper, including a reinforcing layer, and a foam layer, a cover layer and a printing layer arranged on the two outer surfaces of the reinforced layer in sequence from the inside to the outside; the total thickness of the seven-layer melted co-extruded stone paper The total thickness of the printing layer accounts for 20% of the total thickness of the seven-layer melt co-extruded stone paper, the total thickness of the covering layer accounts for 20% of the total thickness of the seven-layer melt co-extruded stone paper, and the total thickness of the foam layer accounts for The seven-layer melt co-extruded stone paper accounts for 50% of the total thickness, and the reinforcing layer accounts for 10% of the seven-layer melt co-extruded stone paper's total thickness.

[0090] The preparation method of seven-layer melting co-extruded stone paper, through the following steps:

[0091] (1) Prepare the printing layer:

[0092] Raw materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com