Ink-jet digital printing paper with gradient functional coating structure

A digital printing, gradient function technology, applied in coating, paper, papermaking, etc., can solve the problems of poor color reproduction, difficult drying, insufficient ink absorption ability, etc., to achieve the effect of solving poor color reproduction and improving ink absorption ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The paper base used is 70 grams of offset paper. Coating solution 1 is first applied from roll to roll to form a deep coating layer, and then coating solution 2 is sprayed on the surface of the dried coating deep layer. The mass percentage of coating solution 2 is composed of It is 70% polydimethylsiloxane, 30% water, adjust the pH value of the solution within the range of 8 to 8.5 with ammonia water, and obtain a sample with a gradient functional coating after drying. After inkjet digital printing, it is proved that the offset coating Cloth paper has better printing color reproduction.

Embodiment 2

[0019] The paper base used is 80 grams of coated paper. Coating solution 1 is first applied from roll to roll to form a deep coating layer, and then coating solution 2 is sprayed on the surface of the dried coating deep layer. Coating solution 2 is ethyl orthosilicate Ester 75%, water 25%, use ammonia water to adjust the pH value of the solution within the range of 8 to 8.5, and after drying, a sample with a gradient functional coating can be obtained. After inkjet digital printing, it is proved that the copper plate coated paper has good printing performance. Color reproduction.

Embodiment 3

[0021] The paper base used is 60 grams of offset paper. Coating solution 1 is first applied from roll to roll to form a deep coating layer, and then coating solution 2 is sprayed on the surface of the dried coating deep layer. Coating solution 2 is ethyl orthosilicate 85% ester, 15% water, adjust the pH value of the solution within the range of 8 to 8.5 with ammonia water, and obtain a sample with a gradient functional coating after drying. After inkjet digital printing, it is proved that the copperplate coated paper has better printing Color reproduction.

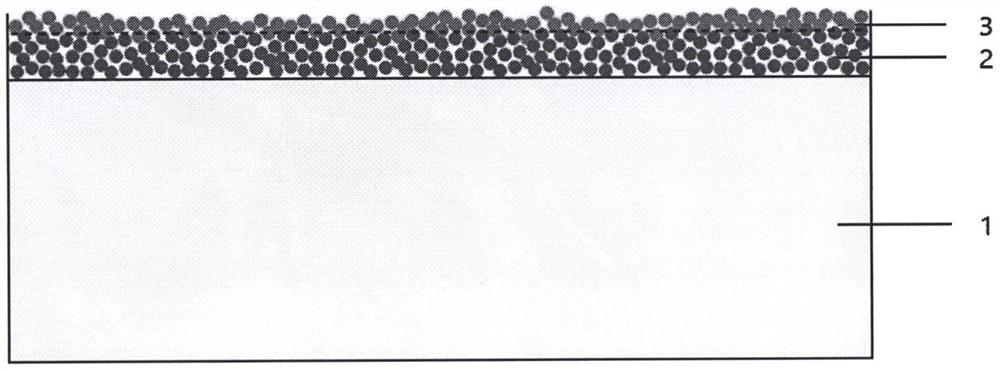

[0022] Based on the above embodiments, this application proposes an inkjet digital printing paper with a gradient functional coating structure, using a coating solution containing spherical particles to build a deep layer of coating with sufficient ink absorption capacity on the surface of the paper, Then spray the coating liquid to form a surface modification layer, improve the ink absorption ability of offset paper and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com