Spiral Cylinder Soil Squeeze Bit and Its Pile-forming Construction Method

A spiral and column technology, applied in the field of construction, can solve the problem of not having hole expansion and diameter expansion, and achieve the effect of saving concrete consumption, strong pulling resistance and high bearing capacity of single pile.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

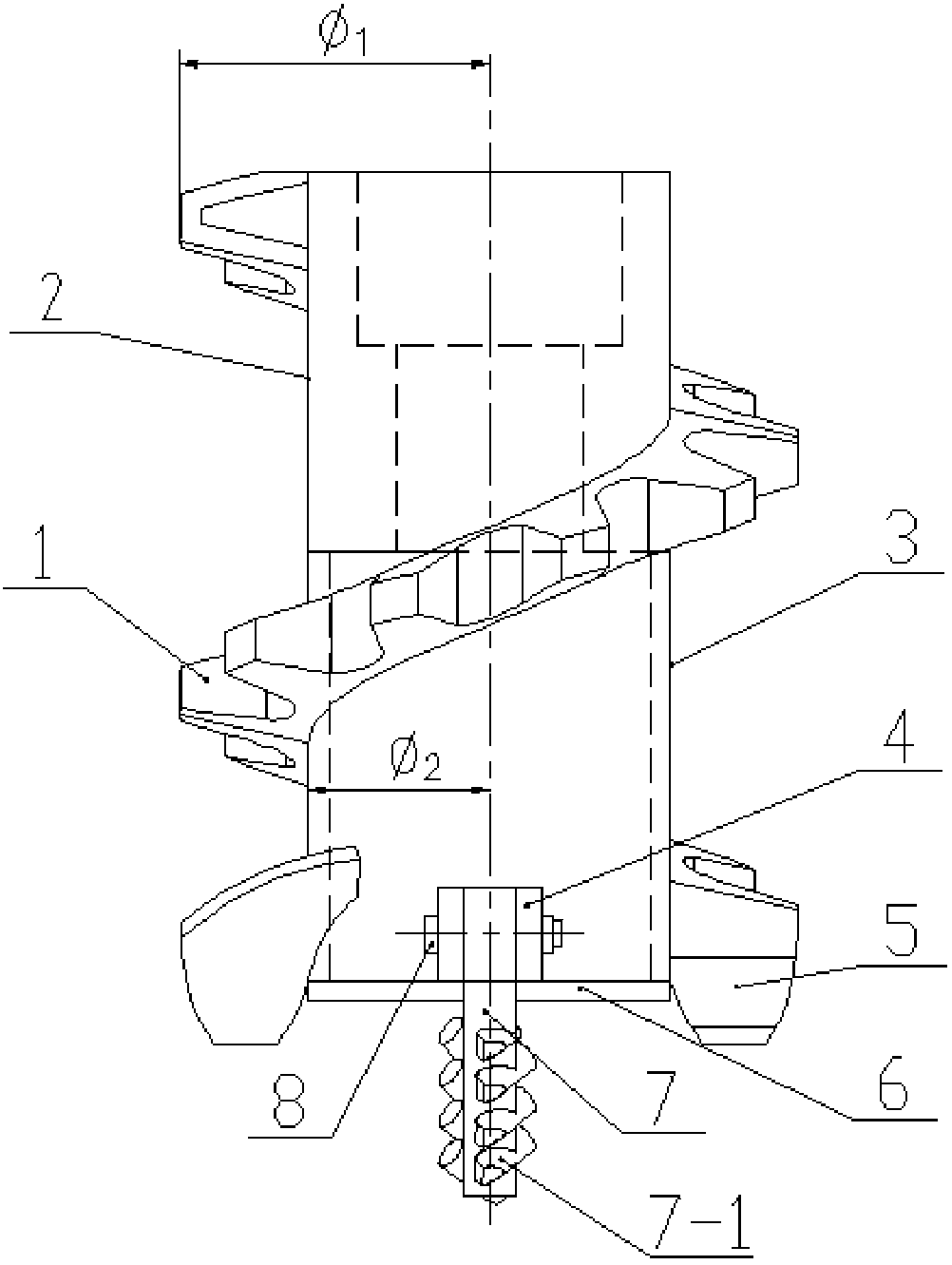

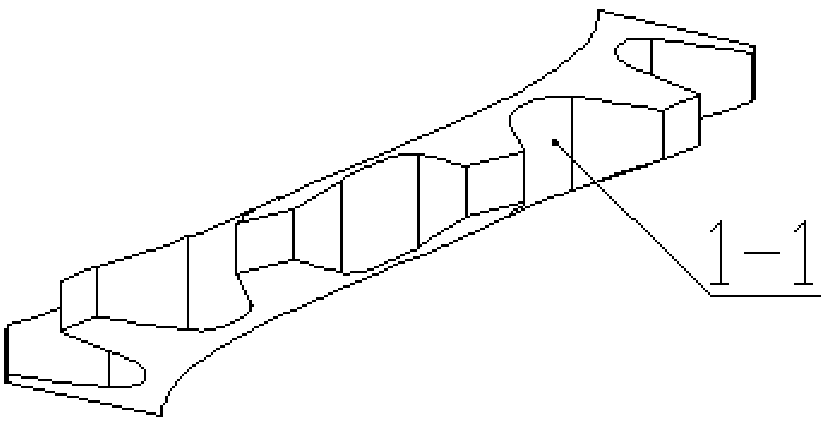

[0032] Embodiment 1 No-connecting rod single drill tip helical cylinder soil squeezing drill bit and construction method for pile formation

[0033] (1) No connecting rod single drill tip helical cylinder soil squeezing drill bit

[0034] Such as Figure 1-Figure 4 As shown, the helical cylinder soil extruding bit includes a helical extruding soil blade 1, a joint 2, a core pipe 3, an ear plate 4, an alloy tooth I5, a baffle plate 6, a drill tip 7 and a pin I8.

[0035] The joint 2 and the core pipe 3 are welded into an integral structure, and the spiral extruding blade 1 is coiled on the joint 2 and the core pipe 3. The radius of the formed circle is φ 1 , the circle radius of joint 2 and core tube 3 is φ 2 . 2φ 1 =350~800mm, where φ 2 =0.58~0.75φ 1 . Pitch H=1.2~1.6φ 1 .

[0036] The lower end of the core tube 3 is provided with an alloy tooth I5 and an ear plate 4 .

[0037] The bottom port of the core tube 3 is installed with a welded baffle plate 6 and a drill ti...

Embodiment 2

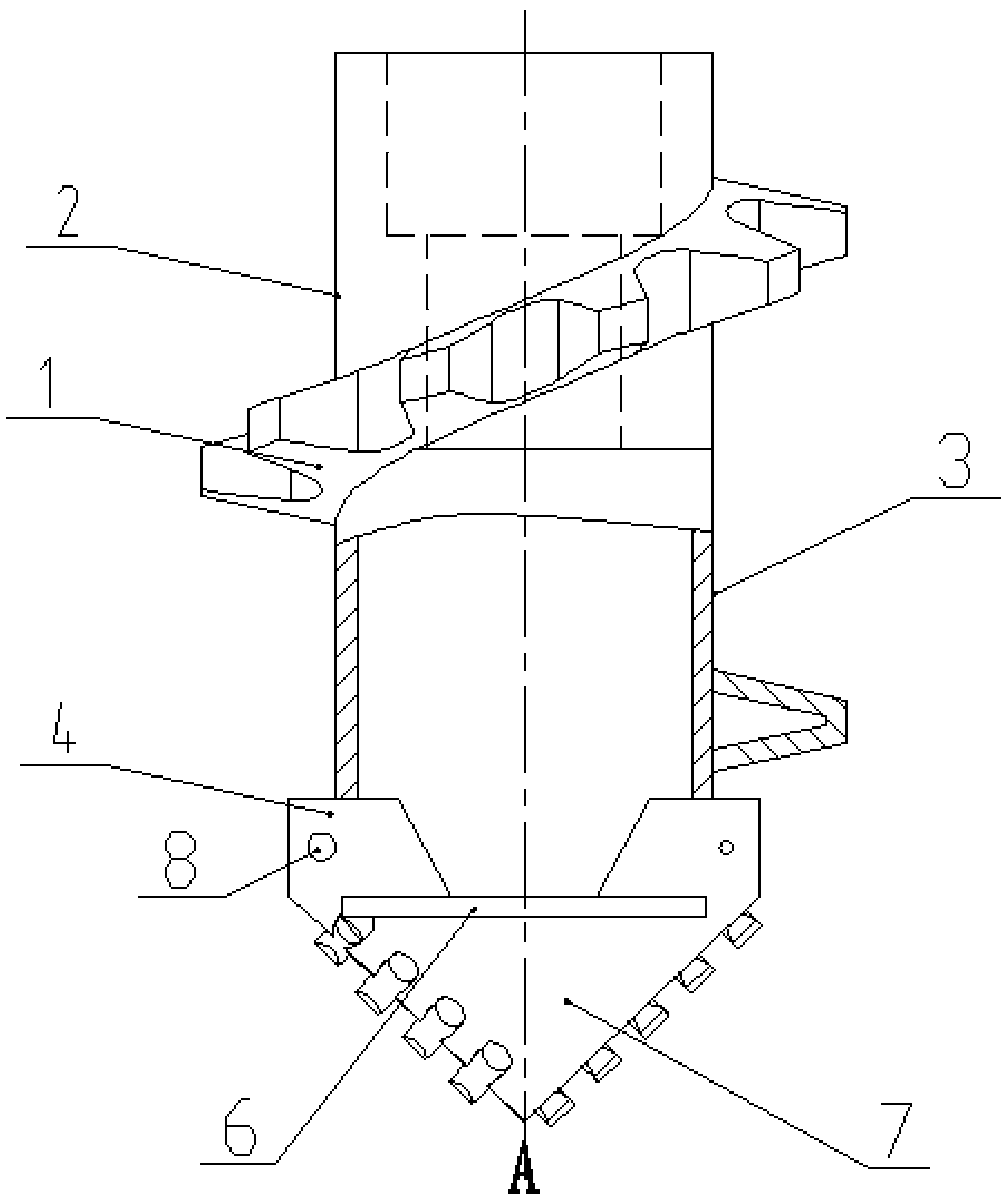

[0046] Embodiment 2 Single-link single-drill point helical cylinder soil-extruding drill bit and pile-forming construction method

[0047] Such as Figure 5-Figure 6 As shown, the single-rod, single-drill-tip helical cylinder soil-extrusion drill bit includes spiral soil-extrusion blade 1, joint 2, core tube 3, lug plate 4, alloy tooth I5, baffle plate 6, drill tip 7, and pin shaft I8 , Connecting rod Ⅰ9-1, connecting rod Ⅱ9-2, pin shaft Ⅱ10, afterburner plate 11, pin shaft Ⅲ12-1, pin shaft Ⅳ12-2, rod seat Ⅰ13-1 and rod seat Ⅱ13-2.

[0048] The joint 2 and the core pipe 3 are welded into an integral structure, and the spiral extruding blade 1 is coiled on the joint 2 and the core pipe 3. The radius of the formed circle is φ 1 , the circle radius of joint 2 and core tube 3 is φ 2 . 2φ 1 =350~800mm, where φ 2 =0.58~0.75φ 1 . Pitch H=1.2~1.6φ 1 .

[0049] The lower end of the core tube 3 is provided with an alloy tooth I5 and an ear plate 4 .

[0050] The bottom port o...

Embodiment 3

[0059] Example 3 Double-connecting-rod, double-drill-tip helical cylinder soil-extruding drill bit and pile-forming construction method

[0060] (1) Double connecting rod double drill point helical cylinder soil squeezing drill bit

[0061] Such as Figure 7-Figure 8 As shown, the double-rod, double-drill-tip helical soil-extruding drill bit includes a helical-extrusion blade 1, a joint 2, a core tube 3, two sets of lugs 4, alloy teeth I5, and two movable baffles I6. -1 constitutes a complete baffle 6, two movably connected drill points I7-2 form a complete drill point 7, two pin shafts I8, connecting rod I9-1, connecting rod II9-2, pin shaft II10, afterburner plate 11, pin shaft III12-1, pin shaft IV12-2, rod seat I13-1 and rod seat II13-2.

[0062] The joint 2 and the core pipe 3 are welded into an integral structure, and the spiral extruding blade 1 is coiled on the joint 2 and the core pipe 3. The radius of the formed circle is φ 1 , the circle radius of joint 2 and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com