Static magnetic field cryogenic treatment method for improving strength and toughness of copper or copper alloy

A cryogenic treatment, copper alloy technology, applied in the field of material strengthening and toughening treatment, to achieve the effect of refining grains, low energy consumption, and mining performance potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

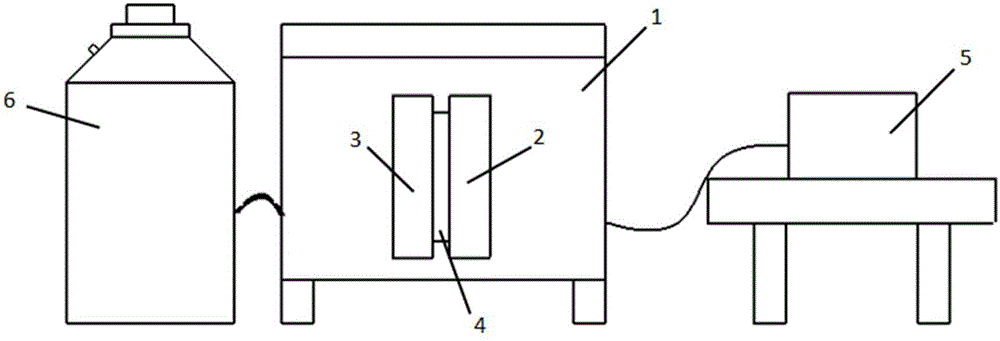

Method used

Image

Examples

example 1

[0022] Static magnetic field cryogenic treatment of example 1 aluminum bronze

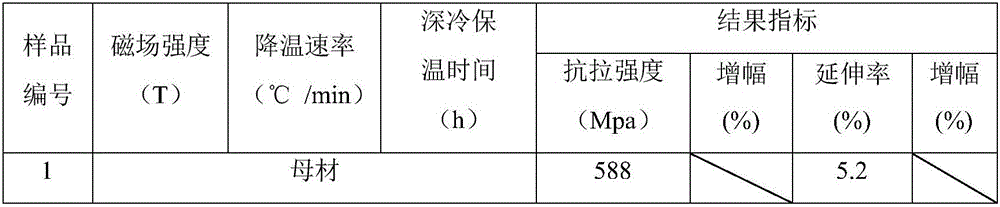

[0023] The composition of the aluminum bronze alloy used in this implementation is shown in Table 1. The sample is processed into a light and thin sheet tensile sample of 45mm×5mm×2mm by wire cutting. The parameters and results of the embodiment are shown in Table 2.

[0024] Table 1 Aluminum Bronze Alloy Composition

[0025] element Al Zn mn Fe Pb Si Cu content(%) 8.0-10.0 0-1.0 0-0.5 2.0-4.0 0-0.01 0-0.1 margin

[0026] Table 2 Test results of static magnetic field cryogenic treatment of aluminum bronze

[0027]

[0028]

[0029] It can be seen from Table 2 that the strength and toughness of aluminum bronze can be significantly improved by cryogenic treatment under a static magnetic field; the tensile strength is increased by 2.6% to 7.1%, and the elongation is increased by 11.6% to 44.2%.

example 2

[0030] Static magnetic field cryogenic treatment of example 2 aluminum brass

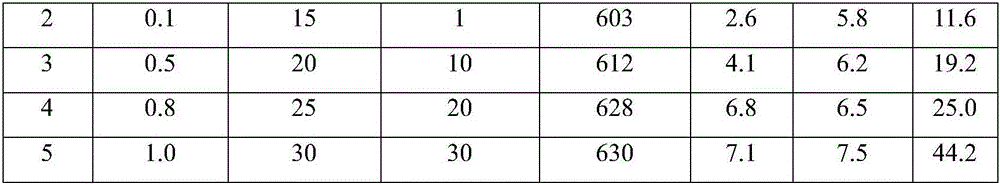

[0031] The composition of the aluminum bronze alloy used in this implementation is shown in Table 3. The sample is processed into a 45mm×20mm×20mm thick plate sample by wire cutting. The parameters and results of the embodiment are shown in Table 4.

[0032] Table 3 Aluminum Brass Alloy Composition

[0033] element Cu sn mn Al Fe Pb Zn content(%) 64.0-68.0 0-0.2 1.5-2.5 6.0-7.0 2.0-4.0 0-0.5 margin

[0034] Table 4 Test results of static magnetic field cryogenic treatment of aluminum brass

[0035]

[0036] It can be seen from Table 4 that the strength and toughness of aluminum brass can be significantly improved by cryogenic treatment under a static magnetic field; the tensile strength is increased by 4.6% to 8.1%, and the elongation is increased by 10.6% to 46.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com