Preparing method of high-electric-conductivity silver-free copper alloy and new material

A technology of silver-copper alloy and high conductivity, which is applied in the direction of conductive materials, conductive materials, metal/alloy conductors, etc., can solve the problems of inconvenient smelting methods and non-dense copper crystal structure, and achieve small resistance, dense crystal structure, and improved Effect of crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

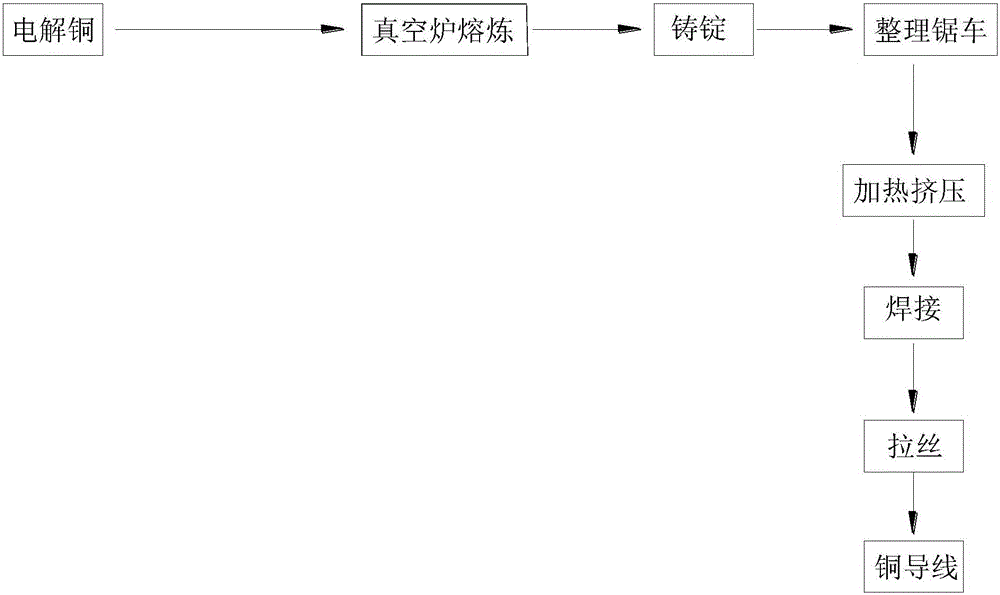

[0029] Refer to figure 1 , A method for preparing a high-conductivity silver-free copper alloy, including the following steps;

[0030] Choose electrolytic copper with a copper content of 99.99% as the copper raw material;

[0031] The vacuum melting furnace is filled with argon to -0.6 to -0.3P when the vacuum degree is -1P;

[0032] After the moisture and residual gas in the heating furnace and raw materials are released, the copper is gradually melted;

[0033] In the copper melting state of 1150-1200 degrees, add 0.5-1% of element manganese, add 0.01-0.05% of rare earth elements cerium and lanthanum, and 0.002%-0.005% of lithium element. And other trace rare elements, so that the copper liquid can completely remove impurities and change the copper metallographic crystal structure to become uniform and compact; improve and enhance the conductive function of the copper alloy.

[0034] Under vacuum conditions, solid solution elements are added to improve the conductivity of copper, r...

Embodiment 1

[0040] A new high-conductivity silver-free copper alloy material is composed of the following components by weight: 0.5% manganese, 0.01% cerium, 0.01% lanthanum, 0.002% lithium, and the rest is copper.

Embodiment 2

[0042] A new high-conductivity silver-free copper alloy material consisting of the following components by weight:

[0043] 1% manganese, 0.05% cerium, 0.05% lanthanum, 0.005% lithium, and the rest is copper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com