Preparation method of carbon nanotube-alumina hybrid reinforced magnesium-aluminum alloy composite material

A nano-alumina, carbon nanotube technology, applied in metal material coating process, nanotechnology, nanotechnology and other directions, can solve the problems of weak interface bonding, poor dispersion effect, poor wettability of the enhanced phase-matrix interface, etc. Mechanical properties, the effect of enhancing mechanical properties, improving interfacial wettability and bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

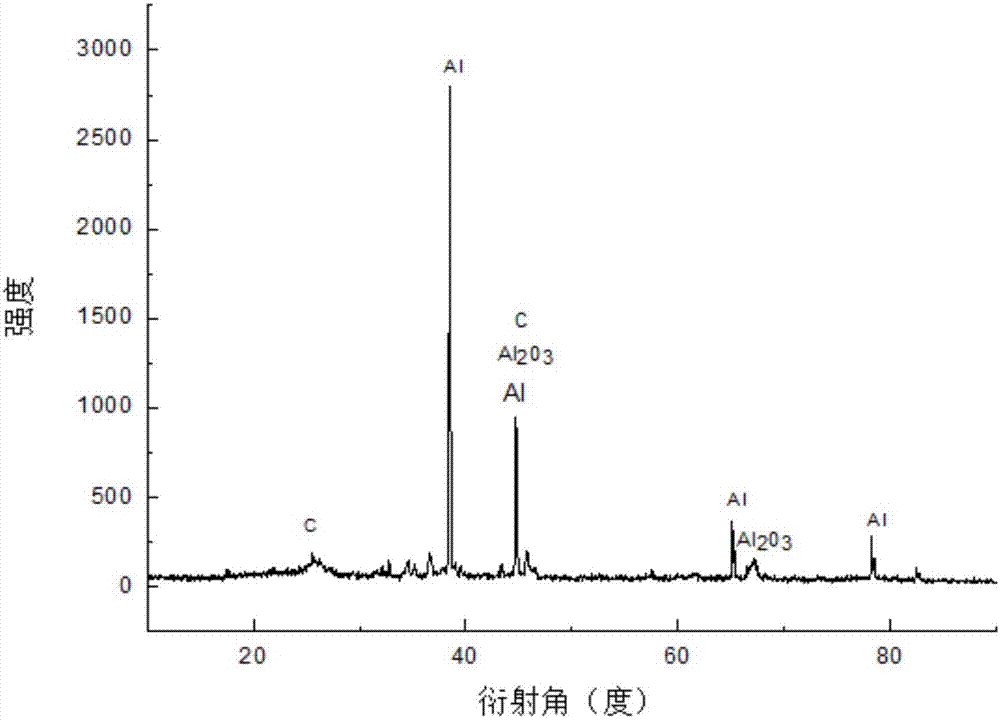

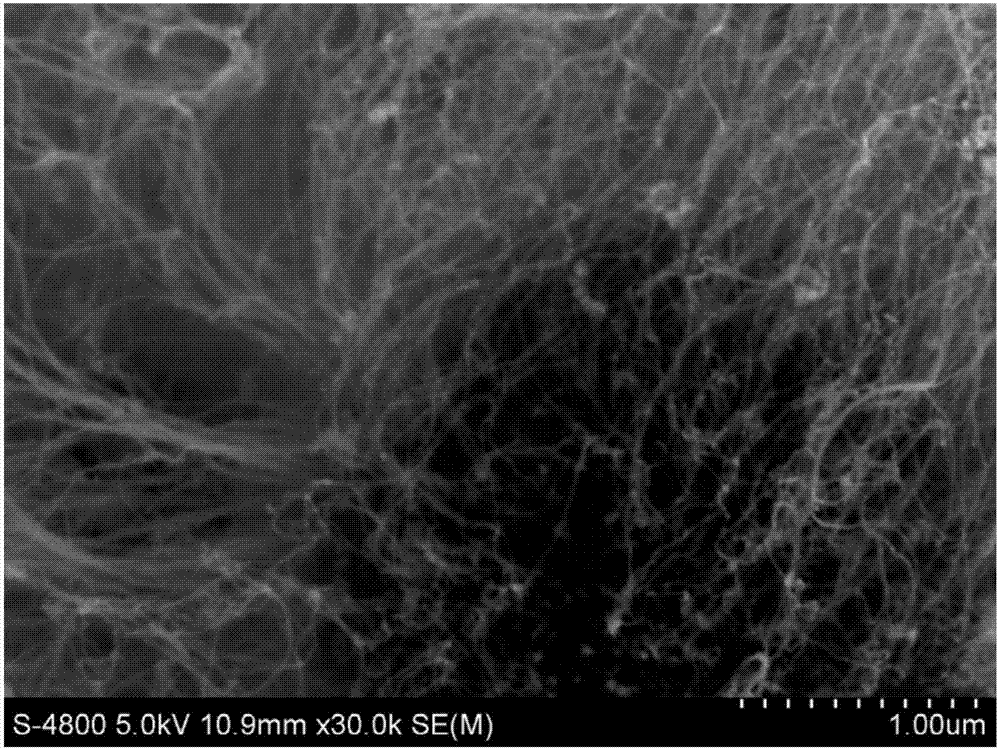

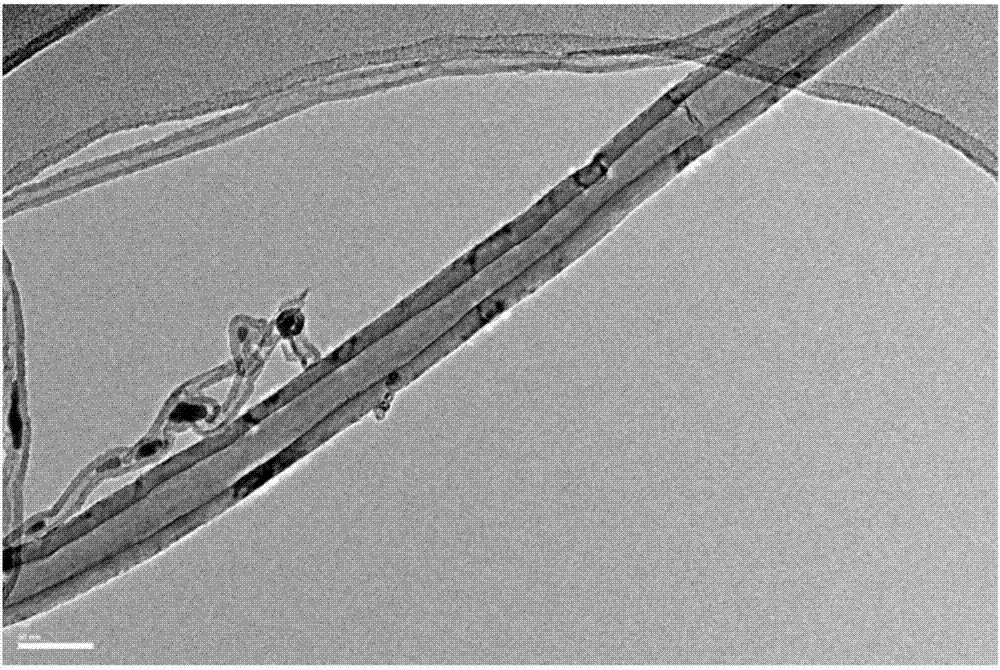

[0039] The first step, preparation of in-situ composite carbon nanotube-alumina and in-situ composite carbon nanotube-aluminum hybrid reinforcement phase:

[0040] Add cobalt acetylacetonate to ethylene glycol to ensure that the concentration of cobalt acetylacetonate in ethylene glycol is 0.8g / mL, and use an ultrasonic disperser to ultrasonically disperse for 16 minutes to fully dissolve cobalt acetylacetonate in ethylene glycol. To obtain the ethylene glycol solution of cobalt acetylacetonate, the mixed powder of spherical nano-alumina particles with a particle diameter of 80 nm and aluminum powder with a particle diameter of 40 μm is placed in a volume of 50 cm 3 In the quartz ark, the mass percentage of nano-alumina and aluminum is guaranteed to be 0.8:1. The quartz ark is placed in the constant temperature zone of the horizontal tube furnace. After closing the tube furnace, the vacuum degree at the place of the quartz ark reaches - 0.08MPa, then argon gas is introduced into...

Embodiment 2

[0049] The first step, preparation of in-situ composite carbon nanotube-alumina and in-situ composite carbon nanotube-aluminum hybrid reinforcement phase:

[0050] Add cobalt acetylacetonate to ethylene glycol to ensure that the concentration of cobalt acetylacetonate in ethylene glycol is 0.1g / mL, and ultrasonically disperse for 3 minutes in an ultrasonic disperser to fully dissolve cobalt acetylacetonate in ethylene glycol. To obtain the ethylene glycol solution of cobalt acetylacetonate, put the mixed powder of spherical nano-alumina particles with a particle diameter of 10 nm and aluminum powder with a particle diameter of 10 μm in a volume of 50 cm 3 In the quartz ark, the mass percentage of nano-alumina and aluminum is guaranteed to be 0.7:1. The quartz ark is placed in the constant temperature zone of the horizontal tube furnace. After closing the tube furnace, the vacuum degree at the place where the quartz ark is located reaches - 0.1MPa, then argon gas was introduced...

Embodiment 3

[0054] The implementation conditions and process of this embodiment are the same as those of Example 2, except that the mass percentage of nano-alumina and aluminum in the first step is 0.9:1, and a carbon nanotube-alumina hybrid reinforced magnesium-aluminum alloy composite material is obtained. In the carbon nanotube-alumina hybrid reinforced magnesium-aluminum alloy composite material, the mass percentage of carbon nanotubes is 1.88%, the mass percentage of aluminum oxide is 16.87%, the mass percentage of aluminum is 18.75%, and the rest is magnesium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com